Method for improving acid production rate of L-phenylalanine genetic engineering bacterial

A technology of genetically engineered bacteria and phenylalanine, applied in the field of bioengineering, can solve problems such as enhancing the ideal metabolic pathway, and achieve the effects of enhancing the accumulation of PEP, improving the ability, and achieving great benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A method of improving the acid production rate of L-phenylalanine genetically engineered bacteria of the present invention, it specifically comprises the following steps:

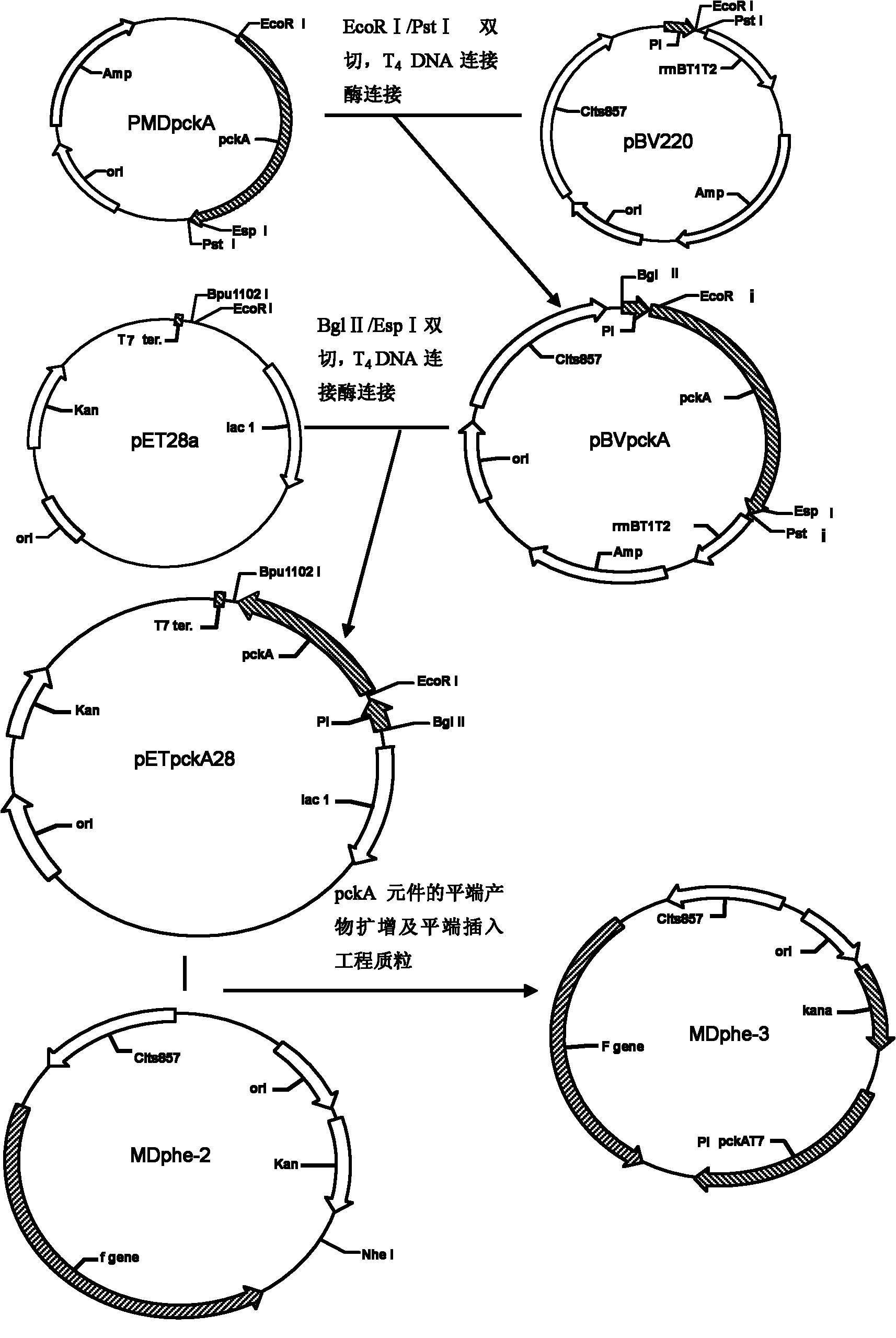

[0043] Step 1: Construction of a new generation of L-phenylalanine engineering plasmid MDphe-3, specifically including the following construction steps (see figure 1 ):

[0044] 1. PCR amplification of the pckA gene with restriction sites

[0045] According to the complete pckA gene sequence (GenBank NO.EG10688) published by NCBI, the primers with restriction sites were designed as follows, and were commissioned to be synthesized by Bioengineering (Shanghai) Co., Ltd. using a DNA synthesizer:

[0046] pckA-F: 5-ATGCGCGTTAACAATGGTTTG-3

[0047] pckA-R: 5- GCTCAGC TTACAGTTTCGGACCAGCC-3

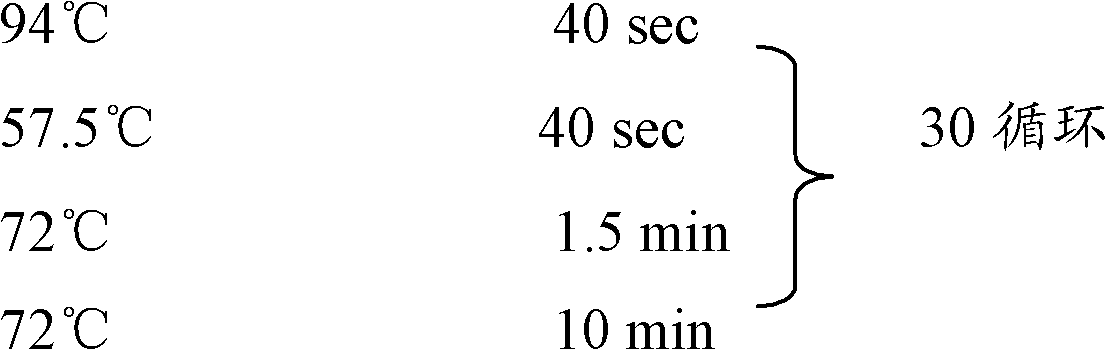

[0048] Among them, the downstream primer has the Esp 1 restriction sequence, the length of the PCR amplified product is 1623bp, and the optimal annealing temperature is 57.5°C. The PCR amplification reaction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com