Anodic aluminum oxide template with three-dimensional gradual-changed hole array nanostructure and preparation method of anodic aluminum oxide template

A technology of anodized aluminum and nanostructures, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of difficult effective regulation and high cost, and achieve the effect of reducing template preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

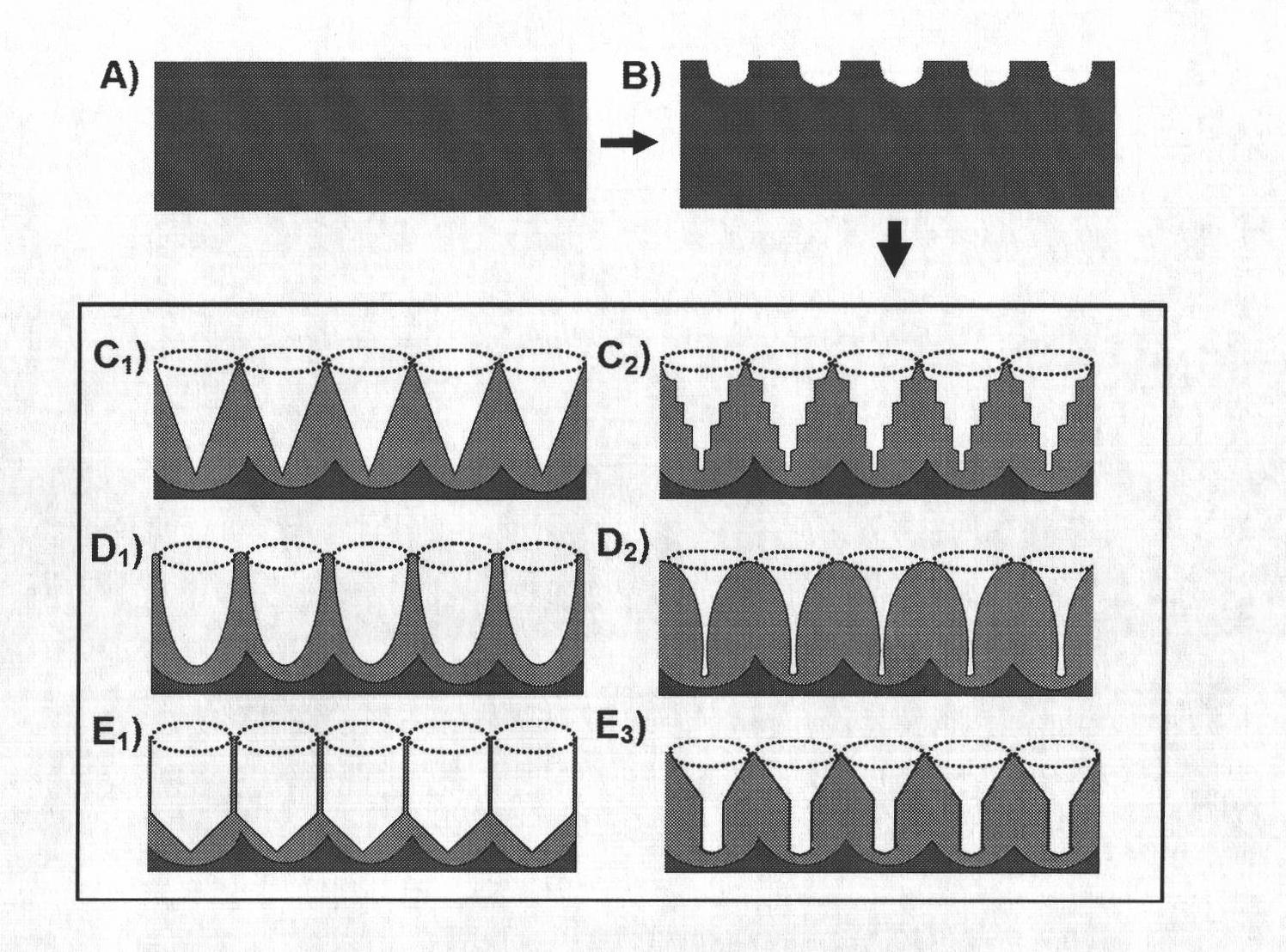

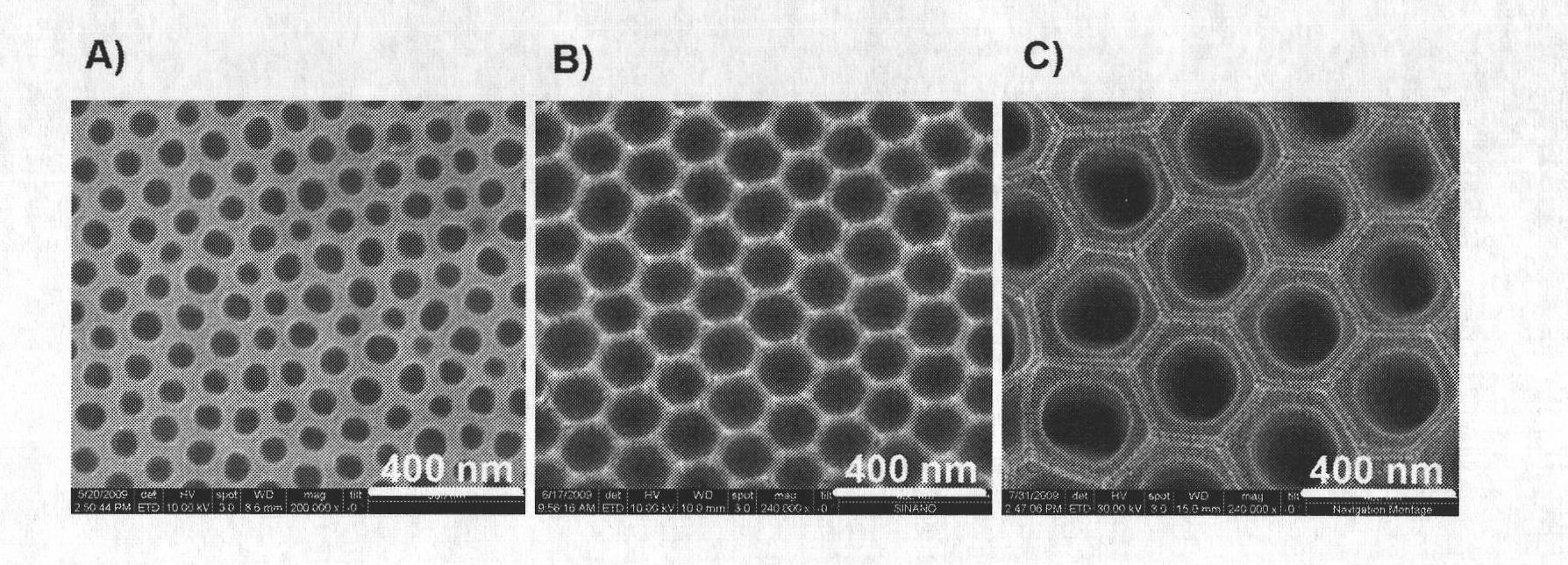

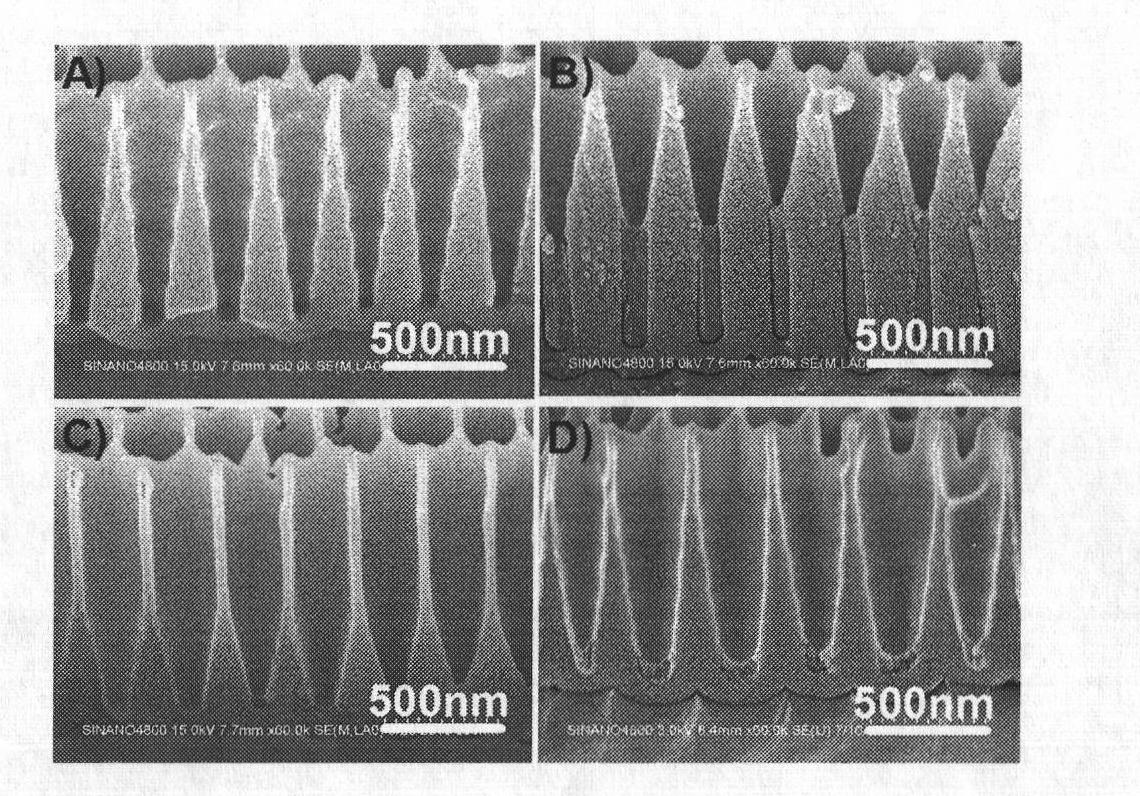

[0047] Embodiment 1 The preparation process of the three-dimensional graded hole array nanostructured anodic aluminum template is as follows:

[0048] Using sulfuric acid solution as electrolyte, sulfuric acid concentration is 0.01M~10M, aluminum sheet is oxidized with high intensity under the voltage of 10V~100V (current density>30mA / cm 2 ). After the oxide layer is stripped off, a regularly arranged pit structure is produced on the surface of the aluminum sheet. The period (pitch, the same below) of the pits is 50 nm to 200 nm. The aluminum sheet with the pit structure is subjected to cyclic oxidation and hole expansion, and the number of cycles is 3 to 20 times. The oxidation conditions are in acidic electrolyte, such as in 0.1vol%~10vol% phosphoric acid solution, the oxidation voltage is 35V~200V, and the oxidation is carried out, and the single oxidation time is 0min~60min, and the time of each oxidation is the same. The hole expansion condition is to perform hole expa...

Embodiment 2

[0049] Embodiment 2 The preparation process of the three-dimensional graded hole array nanostructured anodic aluminum template is:

[0050] The sulfuric acid-oxalic acid mixed solution is used as the electrolyte, the sulfuric acid concentration is 0.0001M~10M, the oxalic acid concentration is 0.001M~5M, and the aluminum sheet is subjected to high-intensity oxidation under the voltage of 15V~150V (current density> 30mA / cm 2 ). After the oxide layer is stripped off, a regularly arranged pit structure is produced on the surface of the aluminum sheet. The period of the pits is 60 nm to 350 nm. The aluminum sheet with the pit structure is subjected to cyclic oxidation and hole expansion, and the number of cycles is 3 to 20 times. The oxidation conditions are in acidic electrolyte, such as in 0.001M ~ 5M oxalic acid solution, the oxidation voltage is 25V ~ 300V, and the oxidation is carried out. The single oxidation time is 0min ~ 60min, and the time of each oxidation is the same ...

Embodiment 3

[0051] Embodiment 3 The preparation process of the three-dimensional graded hole array nanostructured anodic aluminum template is as follows:

[0052] The oxalic acid solution is used as the electrolyte, the oxalic acid concentration is 0.01M-1M, and the aluminum sheet is subjected to high-intensity (current density> 30mA / cm) under the voltage of 15V-200V. 2 ) oxidation. After the oxide layer is stripped off, a regularly arranged pit structure is produced on the surface of the aluminum sheet. The period of the pits is 150 nm to 380 nm. The aluminum sheet with the pit structure is subjected to cyclic oxidation and hole expansion, and the number of cycles is 3 to 20 times. , For example, in the mixed solution of oxalic acid and sulfuric acid, the concentration of sulfuric acid is 0.0001M~10M, the concentration of oxalic acid is 0.001M~5M, the oxidation voltage is 45V~400V, and the oxidation is carried out, and the oxidation time is 0min~450min each time, and the single oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com