Observation method of Ti-Ni alloy metallographic structure

A technology of metallographic structure and titanium-nickel alloy, which is applied in the direction of measuring devices, preparation of test samples, material analysis through optical means, etc., can solve the problems of pseudo-structure, difficult to polish, and inability to obtain titanium-nickel alloy metallographic structure, etc. , to achieve the effect of avoiding pseudo-organization and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

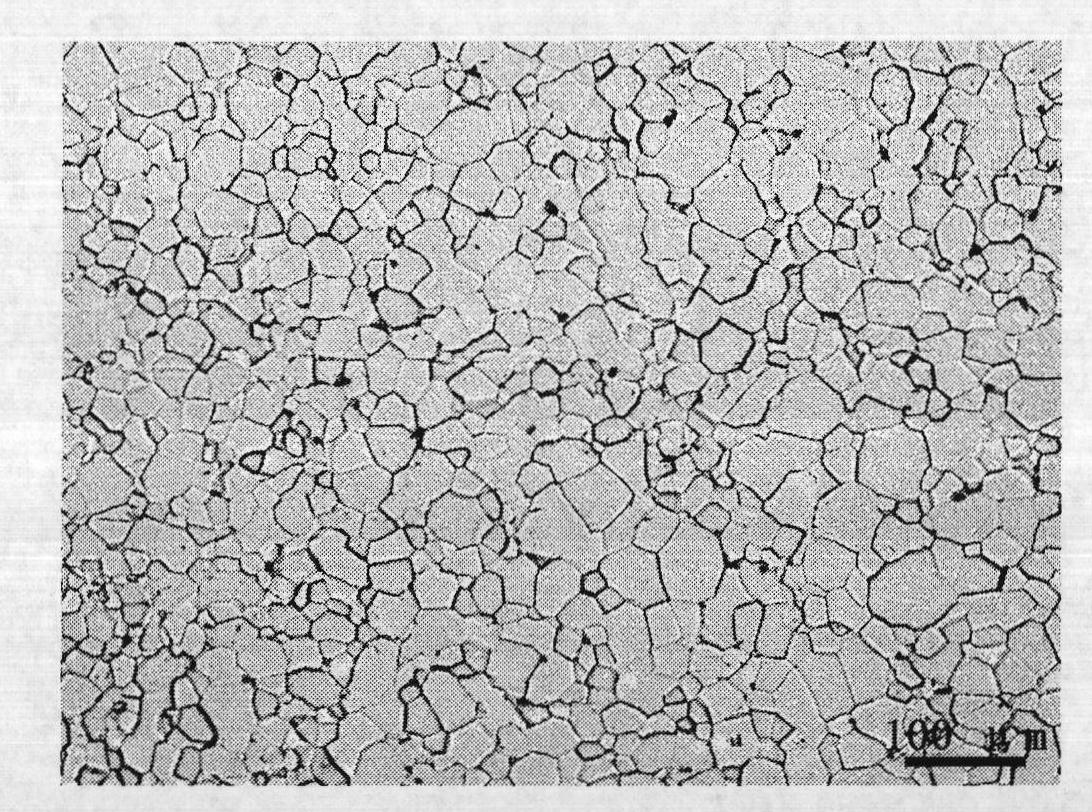

Embodiment 1

[0019] (1) Machining the titanium-nickel alloy sample into a metallographic observation plane;

[0020] (2) Put the machined metallographic observation plane on the grinding machine with a particle size of 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0021] (3) Place the metallographic observation plane, which has been ground and rinsed off the sand grains, on the polishing machine, and use Cr 2 o 3 The solution is used as a polishing agent for mechanical polishing;

[0022] (4) adopting mass concentration to be 95% H 2 SO 4 , with a mass concentration of 65% HNO 3 , mass concentration is 45% HF and water preparation corrosion solution, with corrosion solution etching step (3) in the metall...

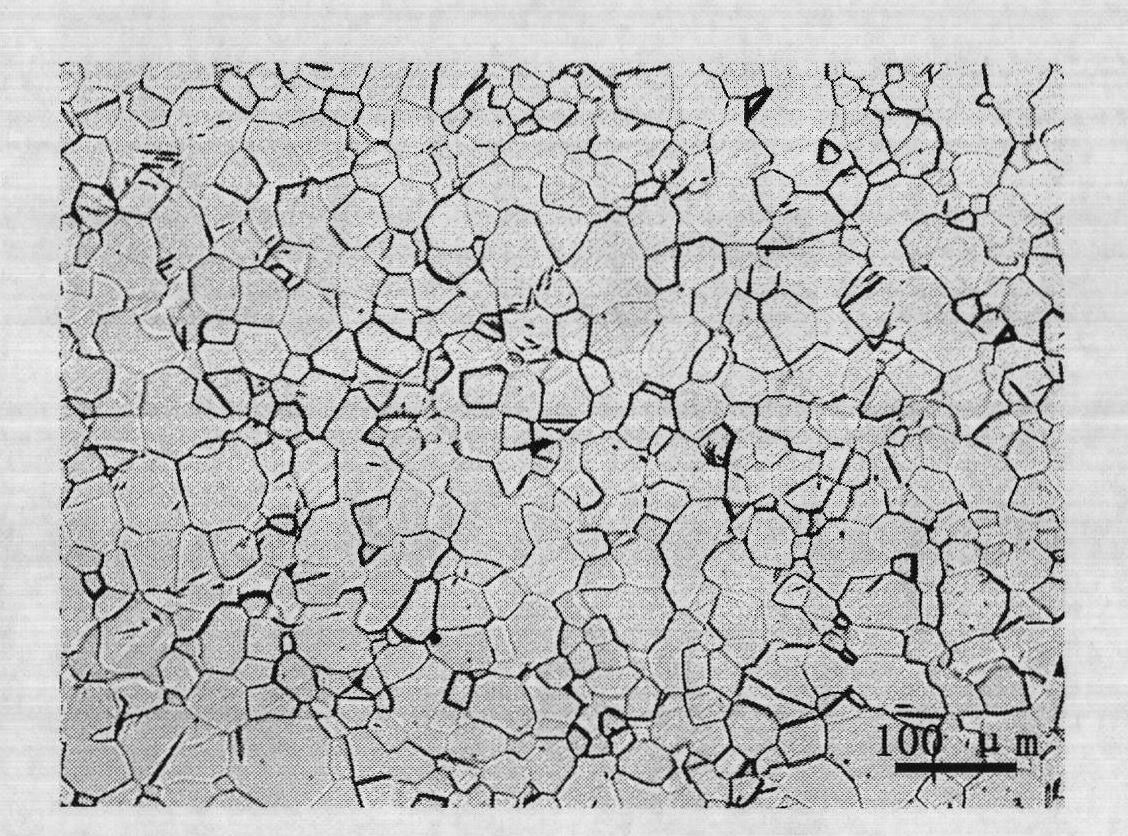

Embodiment 2

[0026] (1) Machining the titanium-nickel alloy sample into a metallographic observation plane;

[0027] (2) Put the machined metallographic observation plane on the grinding machine with a particle size of 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0028] (3) place the metallographic observation plane that rinses off the grit after grinding on the polishing machine, and use diamond powder with a particle size of 2.5 μm as a polishing agent to perform mechanical polishing;

[0029] (4) adopting mass concentration to be 98% H 2 SO 4 , with a mass concentration of 66.5% HNO 3 , mass concentration is 50% HF and water preparation corrosion solution, with corrosion solution corrosion step (3) in ...

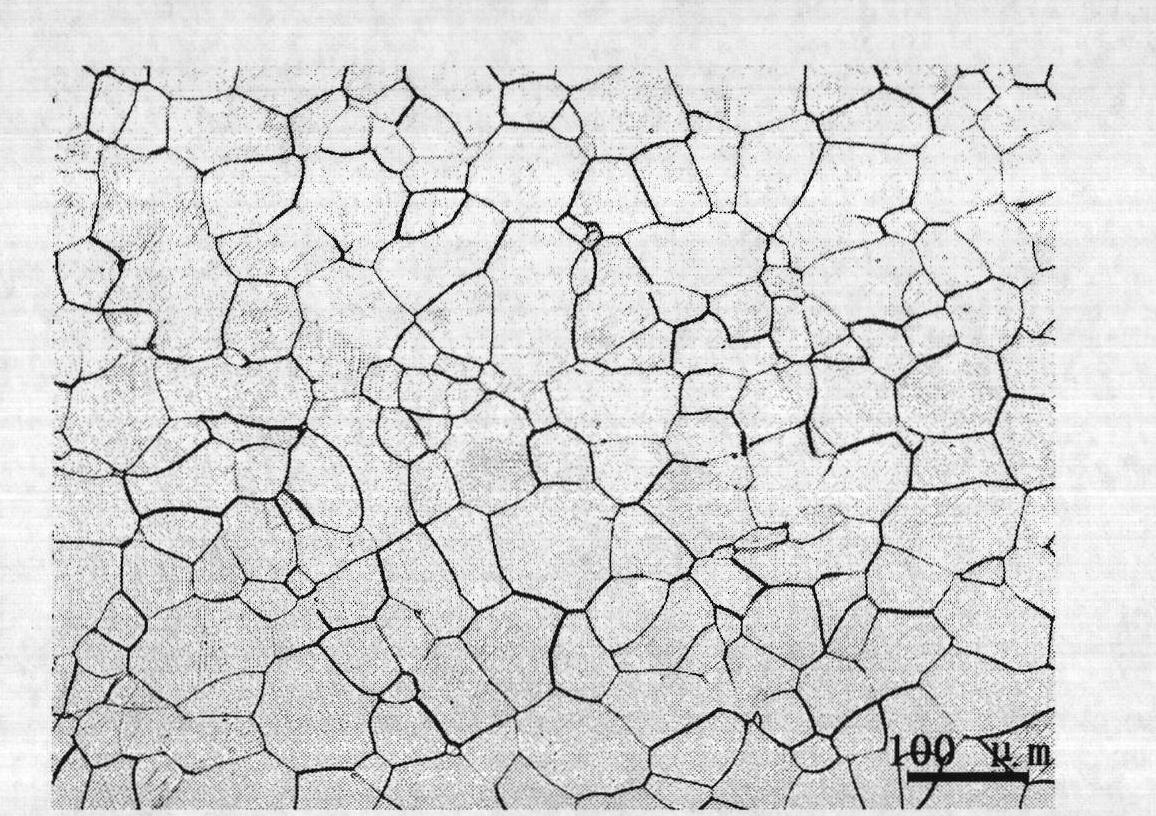

Embodiment 3

[0033] (1) Machining the titanium-nickel alloy sample into a metallographic observation plane;

[0034] (2) Put the machined metallographic observation plane on the grinding machine with a particle size of 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, and the grinding direction is rotated 90° every time the grain size sandpaper is changed to ensure that the last grinding trace is completely eliminated, and the sand grains on the metallographic observation plane are washed away after grinding;

[0035] (3) Place the metallographic observation plane, which has been ground and rinsed off the sand grains, on the polishing machine, and use Cr 2 o 3 The solution is used as a polishing agent for mechanical polishing;

[0036] (4) adopting mass concentration to be 96.5% H 2 SO 4 , with a mass concentration of 65% HNO 3 , a mass concentration of 40% HF and water to prepare an etching solution, etch the mechanically polished metallographic obse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com