Greenhouse quilt rolling machine and operating method thereof

A solar greenhouse and quilt rolling machine technology, which is applied in greenhouse cultivation, botany equipment and methods, horticulture, etc., can solve the problems of complex quilt mechanism, affecting the growth of greenhouse crops, and increasing operating costs, so as to achieve accurate and stable operation, Easy to implement and popularize, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

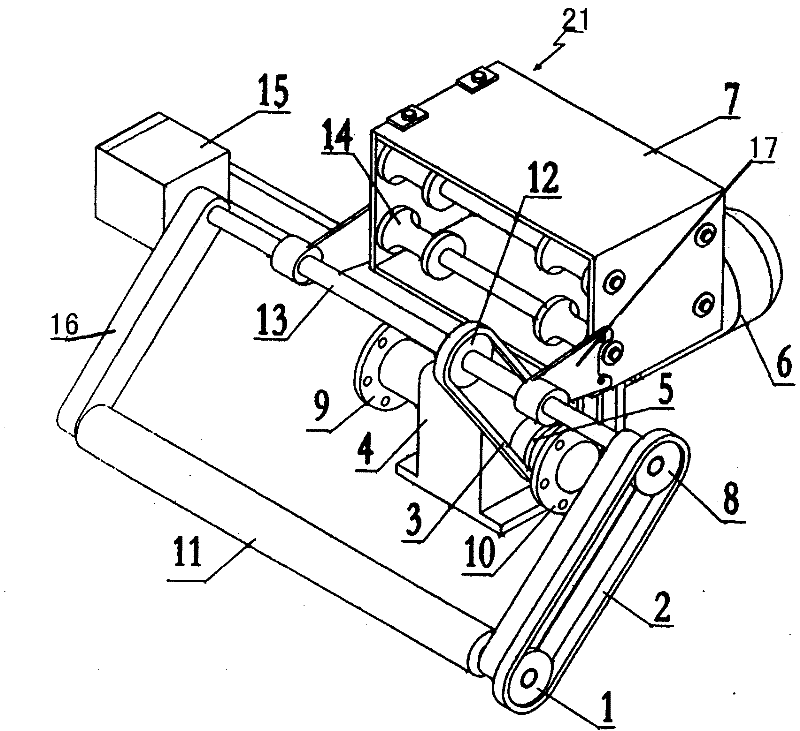

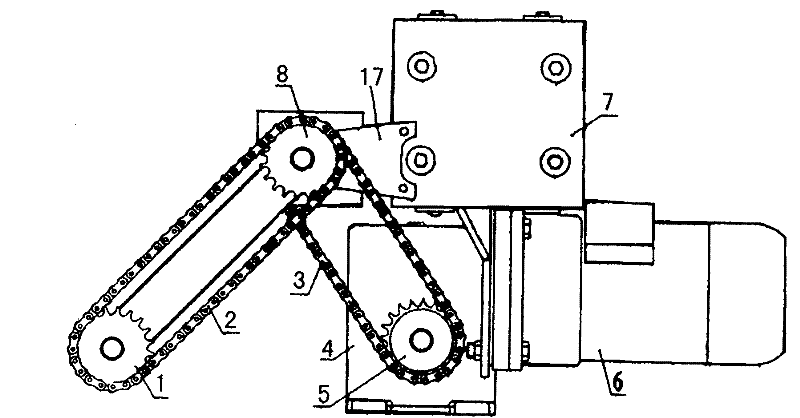

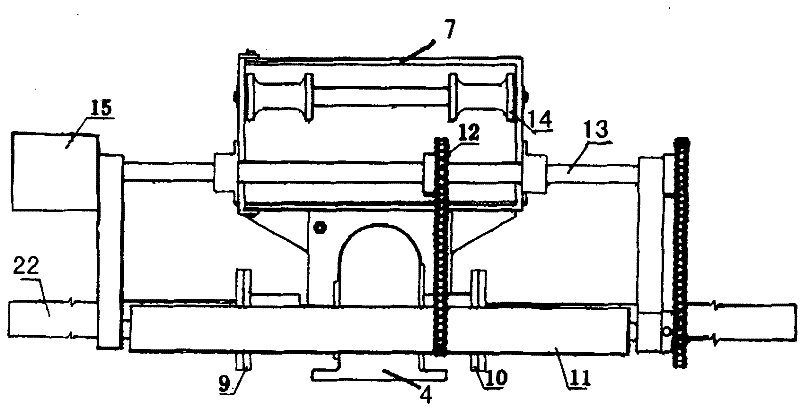

[0020] The invention provides a solar greenhouse roll-up machine and an operation method. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] figure 1 , figure 2 Shown is a structural schematic diagram of the rolling quilt machine in the solar greenhouse. In the figure, the solar greenhouse roll-up machine is composed of a motor 6, a reducer 4, a guide rail support 7, a middle roll-up mechanism, a stroke control box 15, two-side roll-up shafts 22 and double-row arc-shaped guide rails 20. The solar greenhouse consists of three enclosure walls 18 in the east, west and north and a north-south roof arch frame 23. A transparent plastic film 19 is laid on the north-south roof arch frame 23; On the northern enclosure wall and the ground foundation at the south front end of the greenhouse, above the north-south roof arch frame 23 of the solar greenhouse, the roll-up machine 21 is installed on the double-row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com