Halogen-free, inflaming-retarding and high-toughness polyamide composition and preparation method thereof

A polyamide composition and high-toughness technology, applied in the field of halogen-free flame retardant plastic compositions, can solve the problem of lack of relevant data on the flame retardant properties of materials, and achieve the effects of suppressing melting and dripping and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

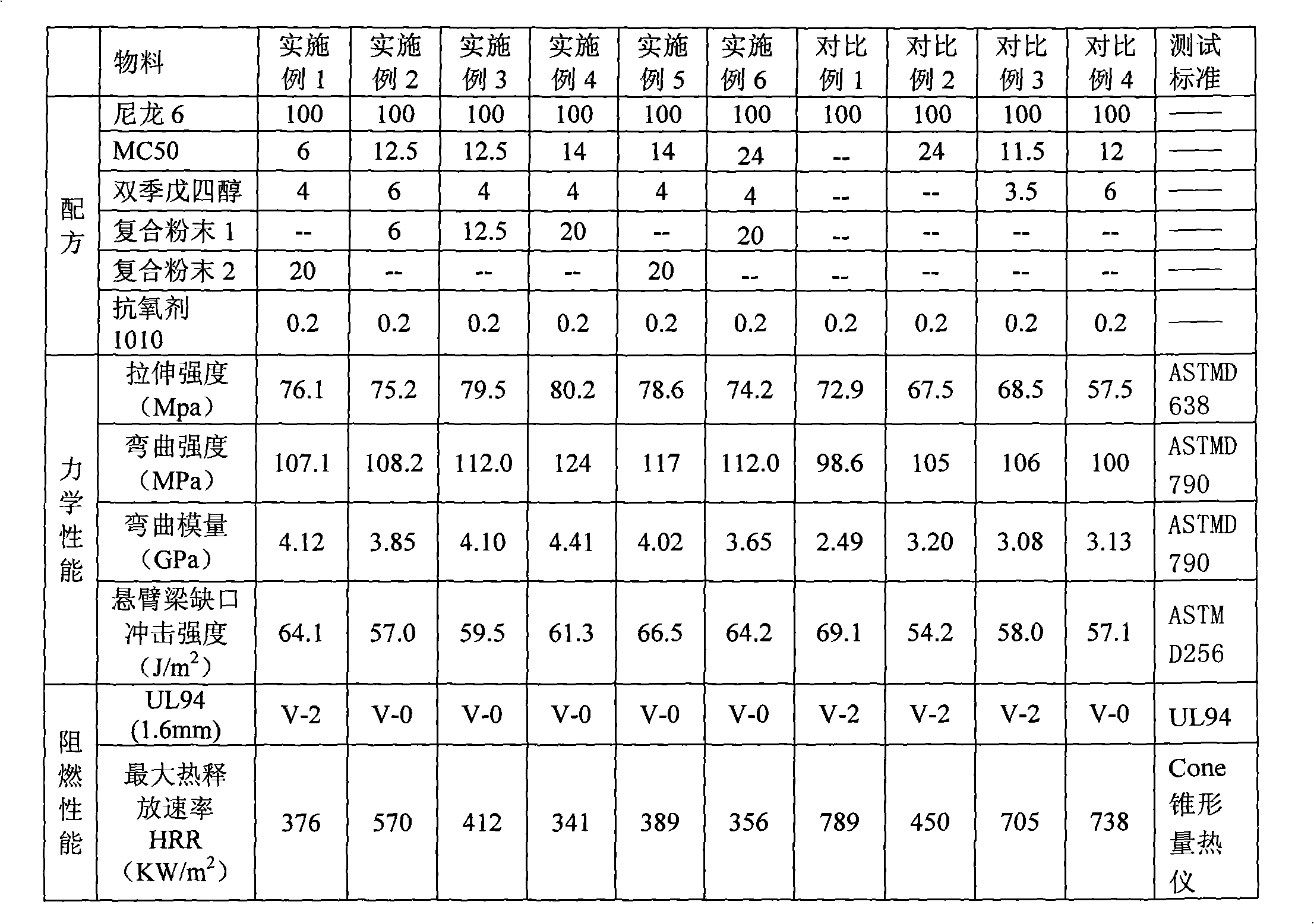

Examples

Embodiment 1~6

[0039] 1. Preparation method of composite powder rubber:

[0040] Acrylate rubber latex radiation crosslinking: 48% by weight of commercially available acrylate latex (the trade mark of Beijing Dongfang Chemical Factory is BC-01) 5Kg, place in the container, add dropwise 72g of isooctyl acrylate of 3% by weight under stirring , stirring was continued for one hour after the dropwise addition was complete. The latex was irradiated with a cobalt source with a dose of 2.5Mrad and a dose rate of 50Gy / min to obtain irradiated acrylate rubber latex. The gel content of the rubber particles is about 80%.

[0041] Organic montmorillonite (obtained through long-chain alkyl quaternary ammonium salt ion exchange reaction, the average particle size of its particles is 99.9% less than 200 mesh, the average wafer thickness is less than 25nm, product brand KD5, Zhejiang Fenghong Clay Chemical Co., Ltd. ) and water in a ratio of 1:10 by weight, and then use a high-shear dispersing emulsifier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com