Powder-metallurgy release yoke and manufacturing method thereof

A technology of powder metallurgy and manufacturing method, which is applied in the direction of transmission device control, components with teeth, belt/chain/gear, etc. It can solve the problems of low product qualification rate, complicated process, and cost of materials, so as to improve the appearance quality, The effect of high production efficiency and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 0.8% C by weight and a small amount of micro-wax powder to 1 part of Fe powder, stir evenly, prepare rigid metal powder, fill it into a preset mold, and press it into an alloy blank under a pressure of 5-9tf / cm2. The billet is sintered at high temperature, the temperature is 1150-1200°C, and it is kept in a reducing gas for 1.5-3h; it is cooled to room temperature in a water jacket; the formed billet is placed in a finishing mold for further extrusion, and finally a small amount of local cutting and trimming set shape. The carbon steel separation fork manufactured in this embodiment is easy to process, but carburizing and quenching is still required to improve the wear resistance of the separation fork.

Embodiment 2

[0033] Fill the alloy powder with a particle size ≥100 mesh into the prefabricated mold, seal and stir evenly, and the ingredients are 3.5% Cu, 2.5% Ni, 2% Mo, 0.8% C, and a small amount of micro wax powder by weight , and the rest is Fe powder. Pressed into an alloy steel blank under a pressure of 7tf / cm2; the blank was sintered at a high temperature of 1180±2°C, and kept in a reducing gas for 2.5h; cooled to room temperature through a water jacket; the formed blank was put into finishing Further extrusion in the mold; finally a small amount of local cutting, trimming and setting.

[0034] Compared with Embodiment 1, this embodiment can save a large amount of raw materials and processing man-hours, improve the processing accuracy of the product, and improve the tensile strength and wear resistance of the product.

Embodiment 3

[0036] Fill the alloy powder with a particle size of ≥100 mesh into the prefabricated mold, and the proportion of each component by weight is: 4.5% Cu, 3% Ni, 3% Mo, 0.8% C, a small amount of micro wax powder, and the rest is Fe powder; pressed into an alloy steel billet under a pressure of 8tf / cm2; the billet was sintered at a high temperature of 1180±2°C, and kept in a reducing gas for 2.5h; cooled to room temperature through a water jacket; the formed billet was placed in Further extrusion in the finishing mold; finally, a small amount of local cutting, trimming and setting.

[0037] Compared with Example 1, this embodiment can save a large amount of raw materials, save processing man-hours, save product cost, improve the tensile strength and wear resistance of the product, and improve the impact toughness index.

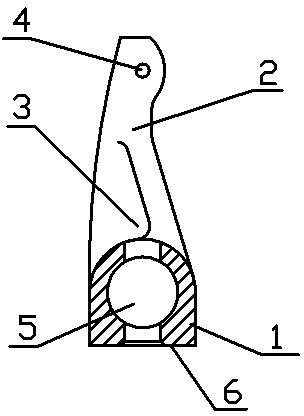

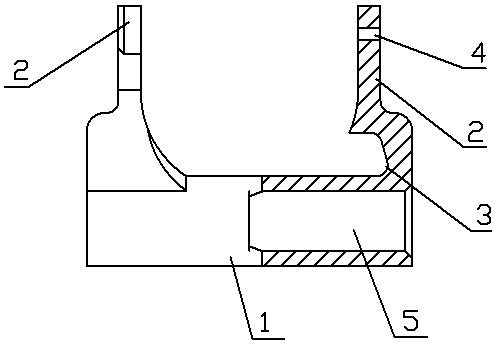

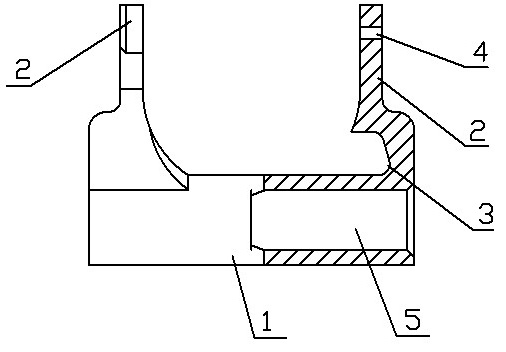

[0038] Such as figure 1 and figure 2 As shown, a powder metallurgy separation fork is composed of a separation fork main body 1 and two separation fork arms 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com