Method for testing influence of water treatment agent on membrane system operation

A technology for water treatment and membrane systems, which is used in measurement devices, analysis of suspensions and porous materials, and scientific instruments. intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

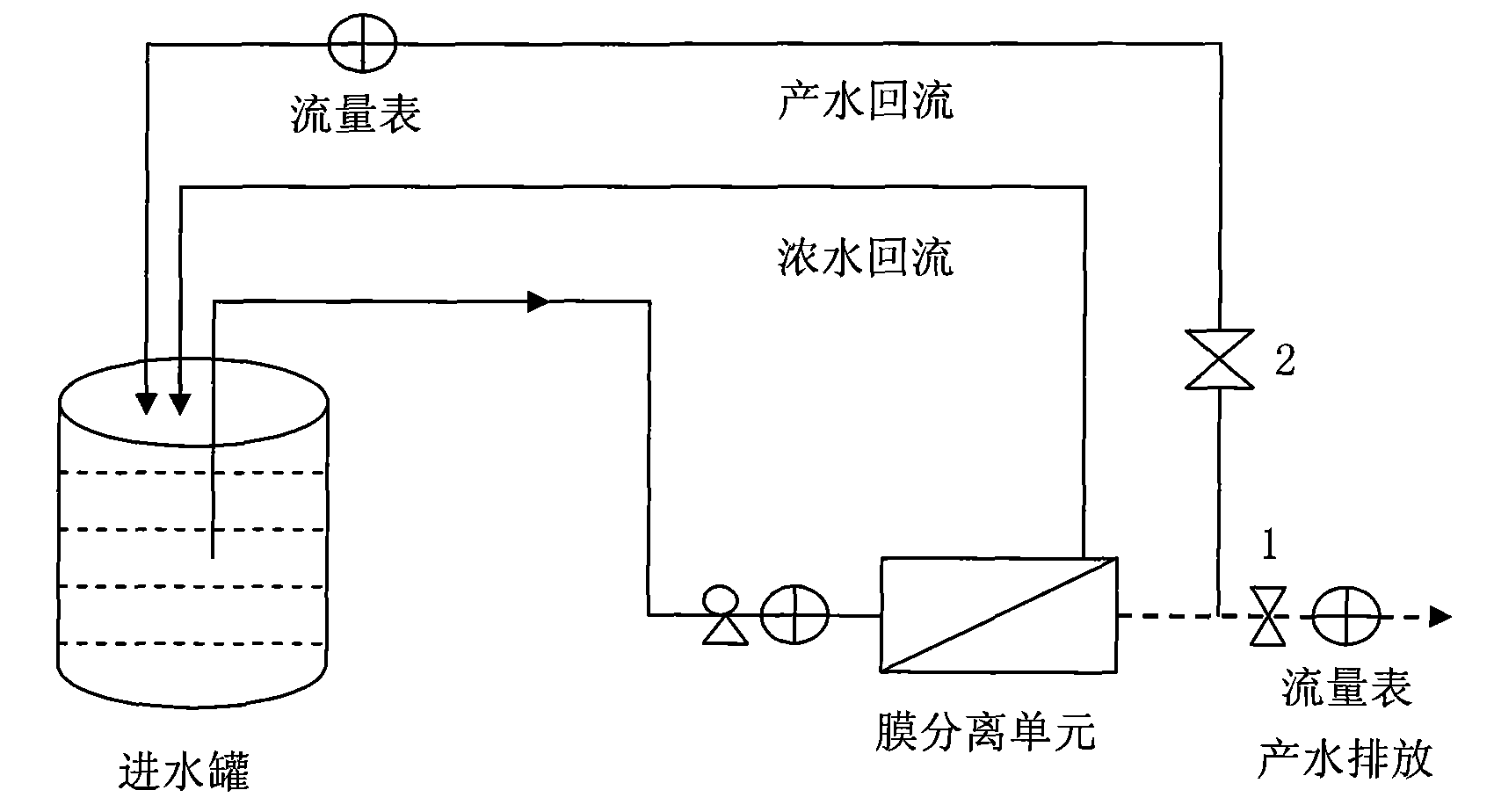

[0031] The membrane system includes: water inlet tank, membrane unit, water inlet pipeline, product water return pipeline, product water discharge pipeline, concentrated water return pipeline:

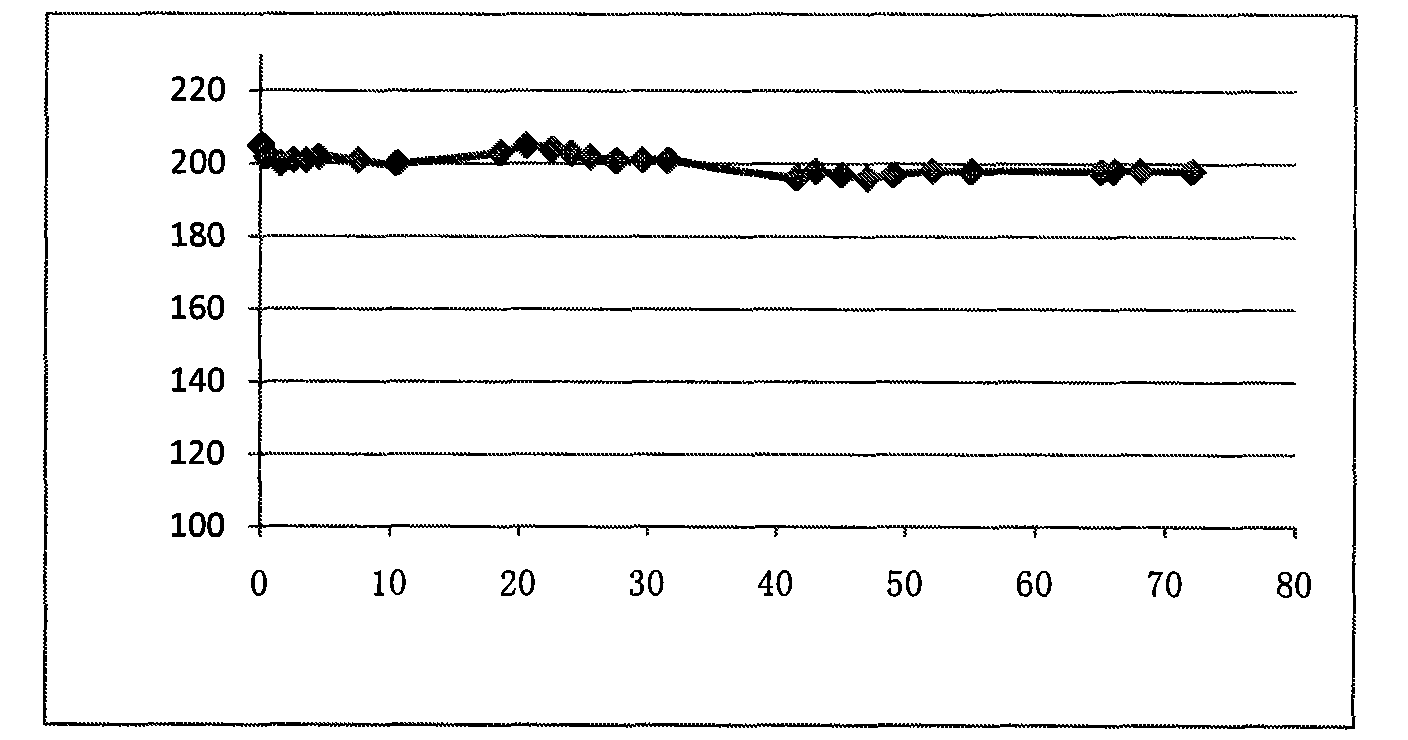

[0032] Dissolve 1g of corrosion and scale inhibitor (mainly composed of sulfonic acid copolymer, PBTCA) water treatment agent in 20L of deionized water solution, stir evenly, and add it to the inlet of the membrane system (CSM RE-1812-50 reverse osmosis membrane) In the water tank, open the membrane system, drain the product water of the membrane system, and return the concentrated water to the water inlet tank. Return to the water inlet tank to measure the water production of the membrane system, and take samples to analyze and measure the concentration of corrosion and scale inhibitors in the aqueous solution in the water inlet tank, and determine the amount of the agent by measuring the amount of total phosphorus and acrylic acid polymer. The concentration basically did not change e...

Embodiment 2

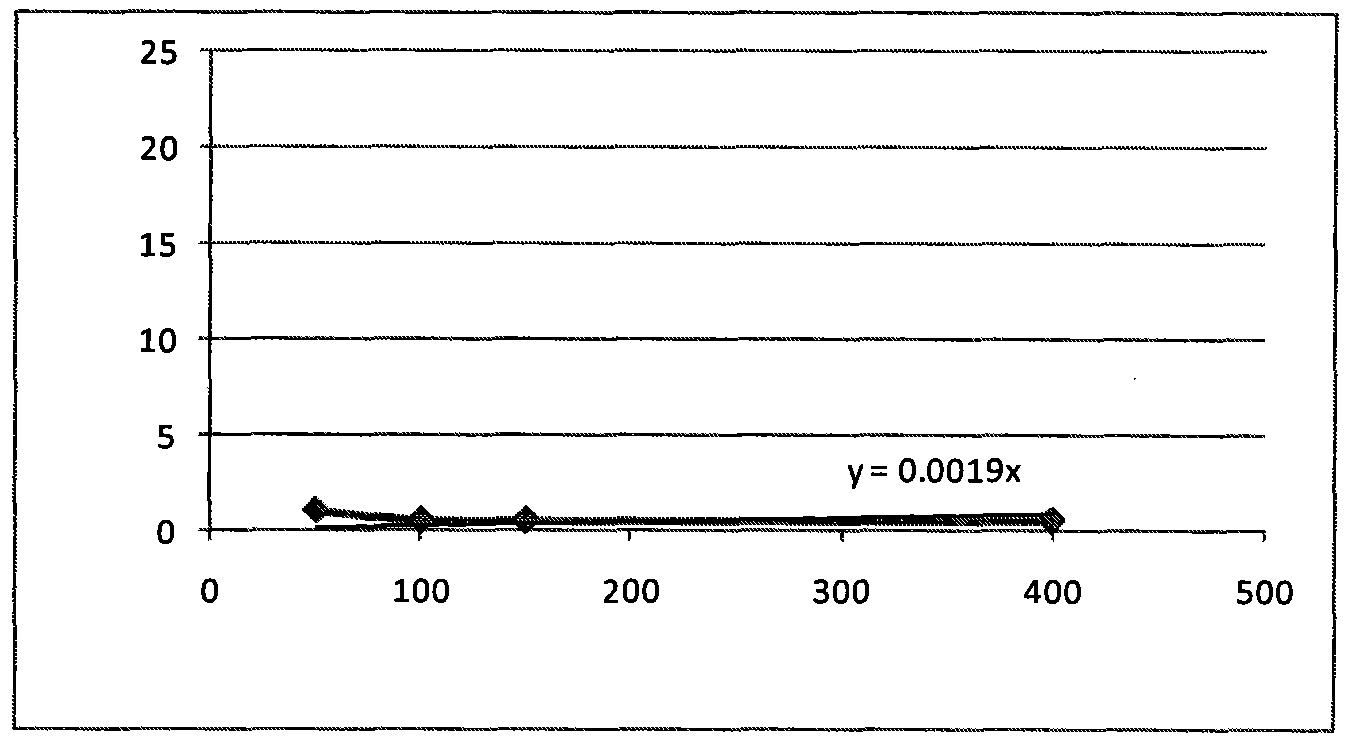

[0034] Dissolve 10g of bactericide (a compound agent, the main component is polyquaternary ammonium salt) water treatment agent in 400L of aqueous solution, stir evenly, and add it to the water inlet tank of the membrane system (BW30-2540 reverse osmosis membrane), Open the membrane system, drain the product water of the membrane system, and return the concentrated water to the water inlet tank. When the discharged water product is 75% of the influent water, return all the product water and concentrated water of the membrane system to the water inlet In the tank, take a sample to analyze and measure the concentration of the fungicide in the aqueous solution in the water inlet tank after concentration. If the fungicide has no effect on the operation of the membrane system, the concentration of the fungicide in the water inlet tank after concentration should be 100mg / L. The actual measurement The value is 90mg / L, and the dose has decreased by 10%, so it is judged that the compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com