Modularized CCD industrial camera

An industrial camera, modular technology, applied in TV, optics, instruments, etc., can solve problems such as inapplicability to detect high-speed moving objects, difficulty in product update and upgrade, and imperfect functions, and achieve the benefits of system resource scheduling, power consumption, etc. The effect of low, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

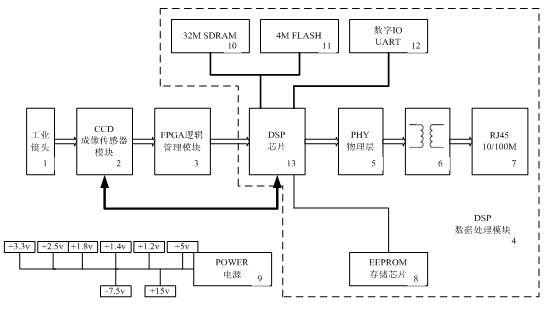

[0030] Such as figure 1 As shown, the hardware part of the modular CCD industrial camera of the present invention includes an industrial lens 1, a CCD imaging sensor module 2, an FPGA logic management module 3, a DSP data processing module 4 and a camera housing (not shown in the figure). The DSP data processing module 4 includes a PHY physical layer chip 5, a network isolation transformer 6, an RJ45 interface 7, an EEPROM chip 8, an SDRAM data memory 10 with a total capacity of 32M, a 4M FLASH program memory 11, a digital IO port 12 and a DSP chip 13. The effect of PHY physical layer chip 5, network isolation transformer 6 and RJ45 interface 7 is to realize the network communication with computer, the effect storage CMOS configuration parameter of EEPROM chip 8, the SDRAM data memory 10 of total capacity 32M is used for the storage of image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com