Method for efficiently manufacturing heat exchange pipes, and production line

A technology of a heat exchange coil and a manufacturing method, which is applied in the field of manufacturing process of the heat exchange coil, can solve the problem that inner micro-ribbed pipes or grooved pipes cannot be used, and achieve the effects of low production cost, efficient operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] High-efficiency heat exchange coil production line, including pipe production equipment, of which the pipe production equipment includes uncoiler 1, embossing device 18, shear butt welding equipment 2, horizontal spiral loop storage machine 4, lead frame 3, forming machine 5. Welding device 6, grinding machine 7, cooling device 8, sizing device 9, eddy current flaw detection 10, straightening unit 11 and cutting device 12, the above equipment are dynamically connected in sequence to form a pipe production line.

Embodiment 2

[0025] The high-efficiency heat exchange coil production line is a continuous pipe production line, including pipe production equipment and bent pipe production equipment. The pipe production equipment is the same as that of Embodiment 1, and the output of the pipe production equipment is directly input into the bent pipe production equipment through the transmission equipment 13. The pipe bending production equipment includes a blanking slide 14, a pipe bending platform 15, a numerically controlled pipe bending machine 16, and a sizing device 17, which are dynamically connected in sequence to form a pipe bending production line.

Embodiment 3

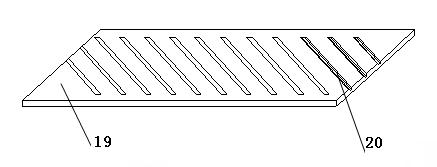

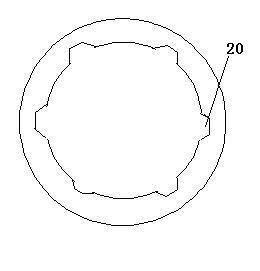

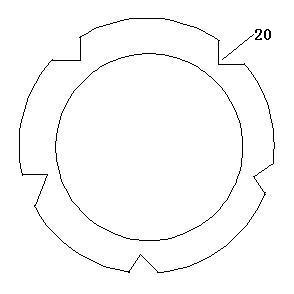

[0027] The manufacturing method of high-efficiency heat exchange coil adopts the production line described in Example 1, and the steel strip is used as the raw material for online continuous production of pipes. After the steel strip is uncoiled, it is first carried out on-line continuous embossing, so that the steel 19 strip is formed with grooves before curling and rounding. The surface of the groove 20, the steel strip after rolling and forming is leveled to the flatness requirements of the pipe, and the material is stored by the looper and then entered into the forming pre-bending machine for forming. After forming, the axial welding is carried out online, and the burr is removed after online cooling The rough tube is obtained, and after cooling, it is sized and cut for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com