Method for producing insulating bricks by utilizing aluminum-electrolyzed waste refractory materials

A refractory, aluminum electrolysis technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problem of aluminum electrolysis waste refractory pollution and other problems, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

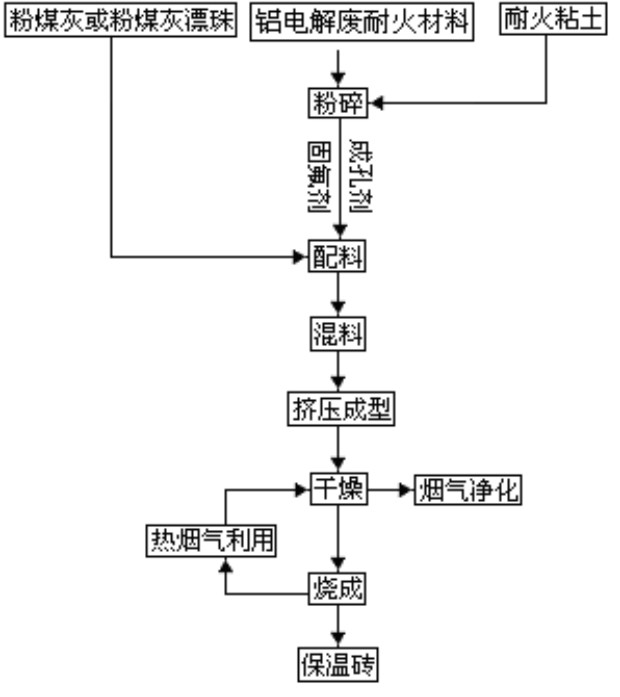

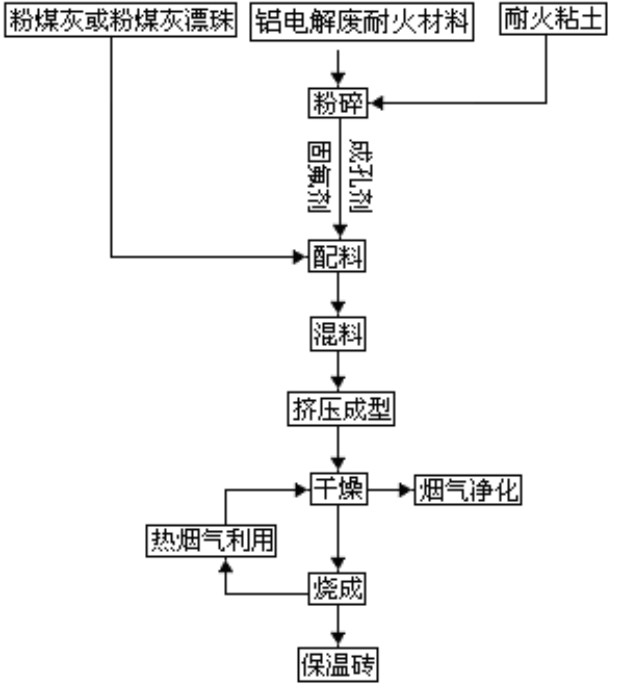

[0025] combine figure 1 1,020 kg of aluminum electrolytic waste refractory materials except carbonaceous materials and silicon carbide bricks are added to the raw materials for production, and added in the form of particles smaller than 2mm; 1,610 kg of fly ash are added; 987 kg of refractory clay are added, crushed to 40 mesh Sieve; add 139 kg of crushed lime; add 300 kg of pore-forming agent and 800 kg of water. The above materials are mixed with a forced mixer to ensure uniform mixing, and then extruded by a semi-dry method, and the formed insulation bricks are sent to the drying room in batches for drying. The drying gas is fired to discharge flue gas. It is adsorbed by alumina, and the firing temperature is controlled at 1000 ° C to 1260 ° C, and the temperature is kept for 2 to 4 hours. It is tested that the soluble fluoride content in the insulation brick is 17.6mg / l, the cyanide content is 0.021mg / l, and the content of harmful substances in the insulation brick and fl...

example 2

[0028] combine figure 1 680 kg of aluminum electrolytic waste refractory materials except carbonaceous materials and carbonized silicon bricks are added to the raw materials for production, and added in the form of particles smaller than 2mm; 967 kg of fly ash and fly ash floating beads are added; 623 kg of refractory clay is added kg, crushed through a 40-mesh sieve; add 103 kg of crushed lime; add 180 kg of pore-forming agent and 500 kg of water. The above materials are mixed with a forced mixer to ensure uniform mixing, and then extruded by a semi-dry method, and the formed insulation bricks are sent to the drying room in batches for drying. The drying gas is fired to discharge flue gas. It is adsorbed by alumina, and the firing temperature is controlled at 1000 ° C to 1260 ° C, and the temperature is kept for 2 to 4 hours. It is tested that the soluble fluoride content in the insulation brick is 15.4mg / l, the cyanide content is 0.019mg / l, and the content of harmful substa...

example 3

[0031] combine figure 1 1,130 kg of aluminum electrolytic waste refractory materials except carbonaceous materials and carbonized silicon bricks were added to the raw materials for production, and added in the form of particles smaller than 2mm; 1,962 kg of fly ash floating beads were added; 1,106 kg of refractory clay were added, crushed 40 mesh sieve; add 197 kg of crushed lime; add 900 kg of water. The above materials are mixed with a forced mixer to ensure uniform mixing, and then extruded by a semi-dry method, and the formed insulation bricks are sent to the drying room in batches for drying. The drying gas is fired to discharge flue gas. It is adsorbed by alumina, and the firing temperature is controlled at 1000 ° C to 1260 ° C, and the temperature is kept for 2 to 4 hours. It is tested that the soluble fluoride content in the insulation brick is 11.8mg / l, the cyanide content is 0.011mg / l, and the content of the insulation brick and the harmful substance in the flue gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com