Preparation of ZnO/ ZnS/ Ag nano-rod array in microchannel

A nanorod array, microchannel technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, to achieve the effect of simple operation and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Configure 0.01M zinc acetate dihydrate ethanol solution, 0.04M sodium hydroxide ethanol solution, 0.05M zinc nitrate hexahydrate solution, 0.05M hexamethylenetetramine solution, configure 2M thioacetamide (TAA) solution and 2M sodium thioglycolate (ST) solution.

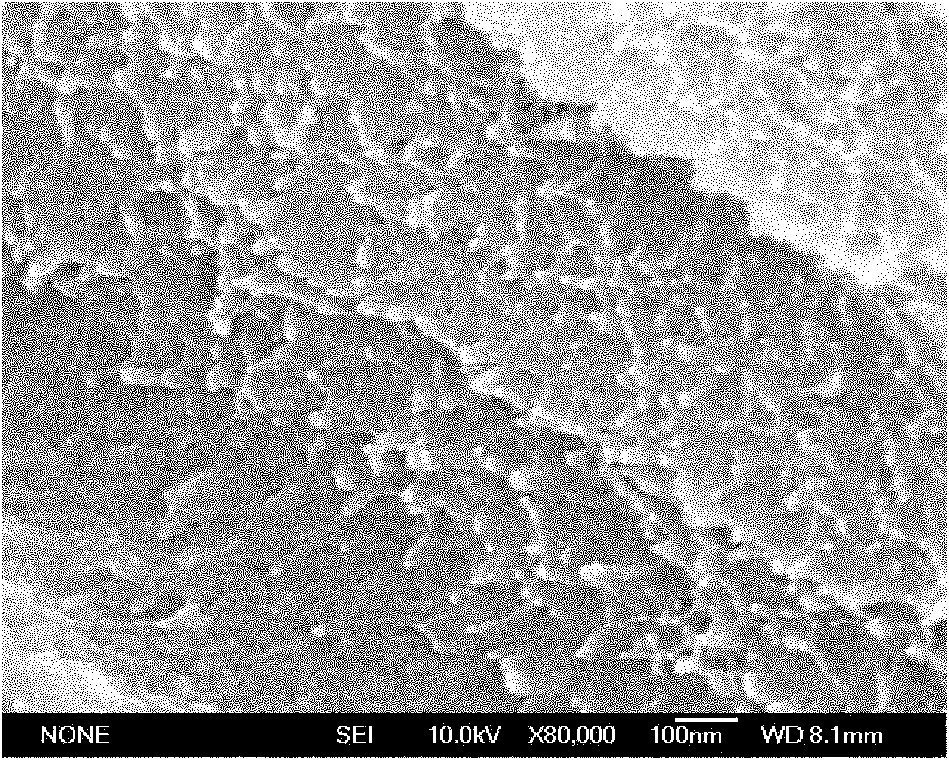

[0033] (1) Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the micro-syringe pump to 10 μL / min, and deliver them to the micro-syringe pre-placed in a 60°C oven at the same time. In the channel, stop conveying after the microchannel is filled. After 2 hours of reaction, raise the temperature of the oven to 150°C and anneal for 1 hour. Clean the microchannel with ethanol and deionized water successively, and dry it at 150°C for 2 hours. A ZnO seed layer film is obtained on the inner surface;

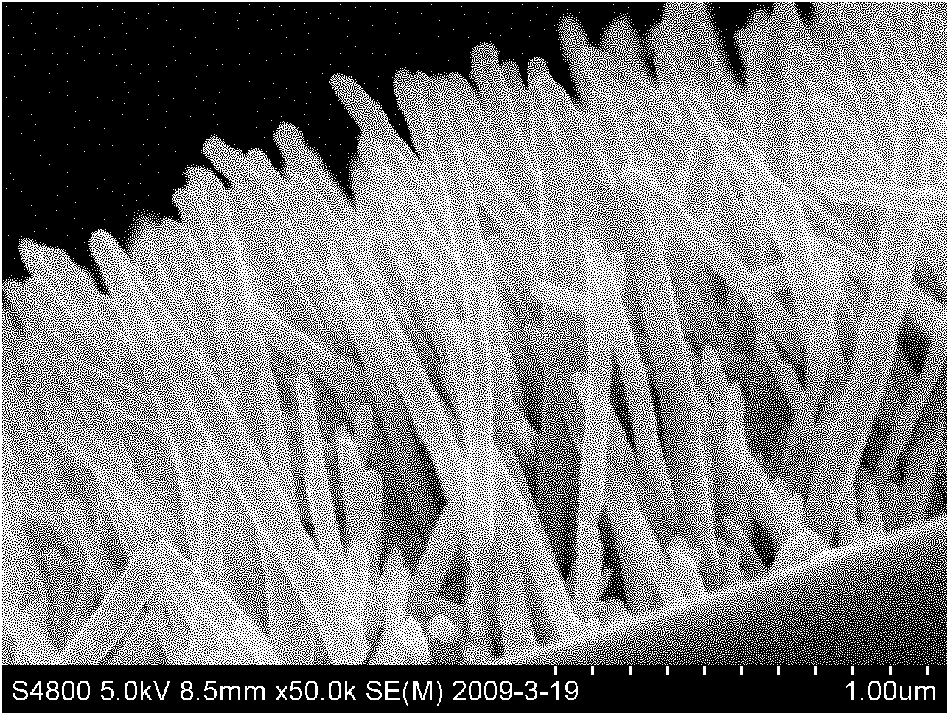

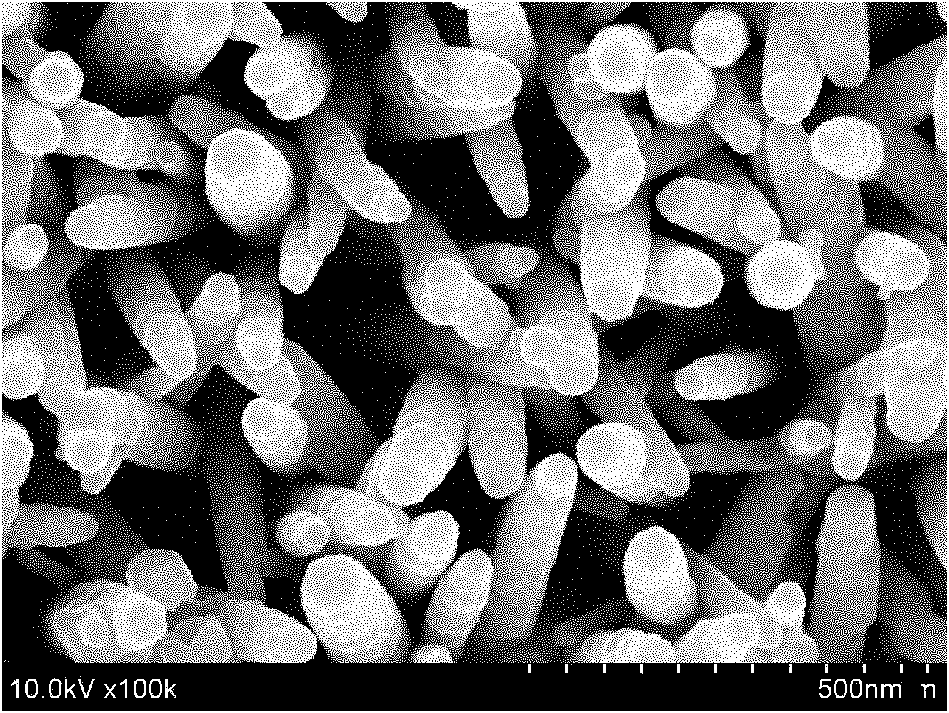

[0034] (2) Simultaneously transport the zinc nitrate hexahydrate solution and the hexamethylenetetramine soluti...

Embodiment 2

[0040] Prepare 0.03M zinc acetate dihydrate ethanol solution, 0.06M sodium hydroxide ethanol solution, 1M zinc nitrate hexahydrate solution, 1M hexamethylenetetramine solution, 1M thioacetamide (TAA) solution and 1M Sodium thioglycolate (ST) solution. (1) Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the micro-syringe pump to 20 μL / min, and deliver them to the micro-syringe pre-placed in a 70°C oven at the same time. In the channel, stop conveying after the microchannel is filled. After 4 hours of reaction, raise the temperature of the oven to 150°C for annealing for 2 hours. Clean the microchannel with ethanol and deionized water successively, and dry it at 170°C for 2 hours. A ZnO seed layer film is obtained on the inner surface;

[0041] (2) Simultaneously transport the zinc nitrate hexahydrate solution and the hexamethylenetetramine solution to the microchannel ...

Embodiment 3

[0047] Prepare 0.02 M zinc acetate dihydrate ethanol solution, 0.05 M sodium hydroxide ethanol solution, 0.08 M zinc nitrate hexahydrate solution, 0.08 M hexamethylenetetramine solution, 0.5 M thioacetamide (TAA) solution and 1M sodium thioglycolate (ST) solution.

[0048] (1) Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the micro-syringe pump to 20 μL / min, and deliver them to the micro-syringe pre-placed in a 65°C oven at the same time. In the channel, stop the transportation after the microchannel is filled, and after 1.5 hours of reaction, raise the temperature of the oven to 150 ° C for 1.5 hours, wash the micro channel with ethanol and deionized water, and dry at 170 ° C for 1.5 hours, Obtain a ZnO seed layer film on the inner surface of the microchannel;

[0049] (2) Simultaneously transport the zinc nitrate hexahydrate solution and the hexamethylenetetramine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com