Multi-zone circulating reaction device and method for olefin polymerization

A technology for olefin polymerization and cyclic reaction, applied in the direction of chemical recovery, etc., can solve the problems of undisclosed reaction gas channeling, uneven distribution of high and low molecular weight of particles, unstable process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Preferred embodiments of the present invention are described in detail as follows.

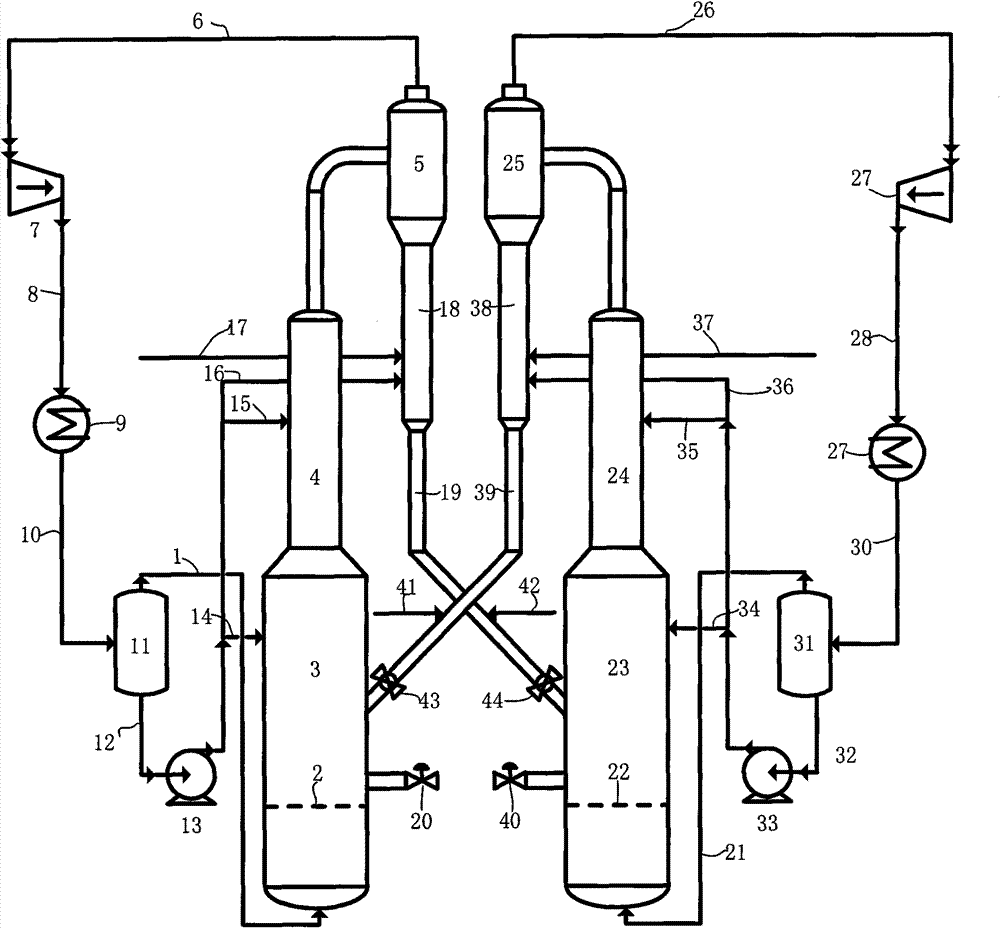

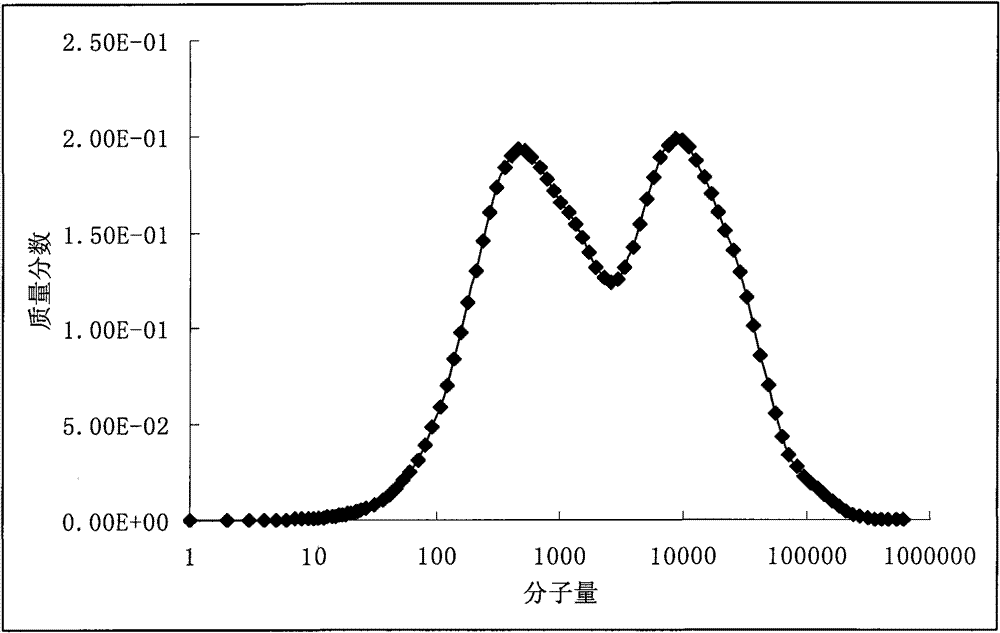

[0102] There are two circulating gas systems in the reaction process. The two reaction conditions and the monomer content are controlled according to the requirements of producing high molecular weight and low molecular weight respectively. The relevant parameters are listed in Table 1.

[0103] The solid catalyst preparation process used in the example is as follows:

[0104] In an inert atmosphere, 28.4 g of MgCl 2, 49.5 grams of absolute alcohol, 10 milliliters of ROL OB / 30 vaseline oil and 100 milliliters of silicone oil with a viscosity of 350CS are introduced into a reactor equipped with a stirrer. The reaction mixture was heated at a temperature of 120 °C with stirring and MgCl 2 The adduct with ethanol, the adduct is kept in a mixed state with the dispersant after melting. The mixture was then introduced while hot into a 1500 ml container equipped with an Ultra Turrax T-45 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com