Coating composition coated on glass surfaces and preparation method thereof

A glass surface and composition technology, applied in the chemical field, can solve the problems of high light pollution and high manufacturing cost, and achieve the effects of reducing hazards, low manufacturing cost, and reducing light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is used for the preparation method of the coating composition of coating glass surface, comprises the following steps:

[0042] S1, prepared by 11% quality water, 80% quality acrylic acid or polyurethane dispersion, 6% quality dipropylene glycol monomethyl ether, 0.9% quality defoamer, 1.5% quality thickener, 0.6% quality Aqueous solvents composed of wetting agents;

[0043] S2, adding a nano-slurry composed of 20% by mass of silicon carbide, 20% by mass of antimony tin oxide, 4% by mass of a wetting and dispersing agent, 4% by mass of a hyperdispersant, and 52% by mass of water;

[0044] S3, mixing the aqueous solvent and the nano slurry in steps S1 and S2 at a ratio of 100:40.

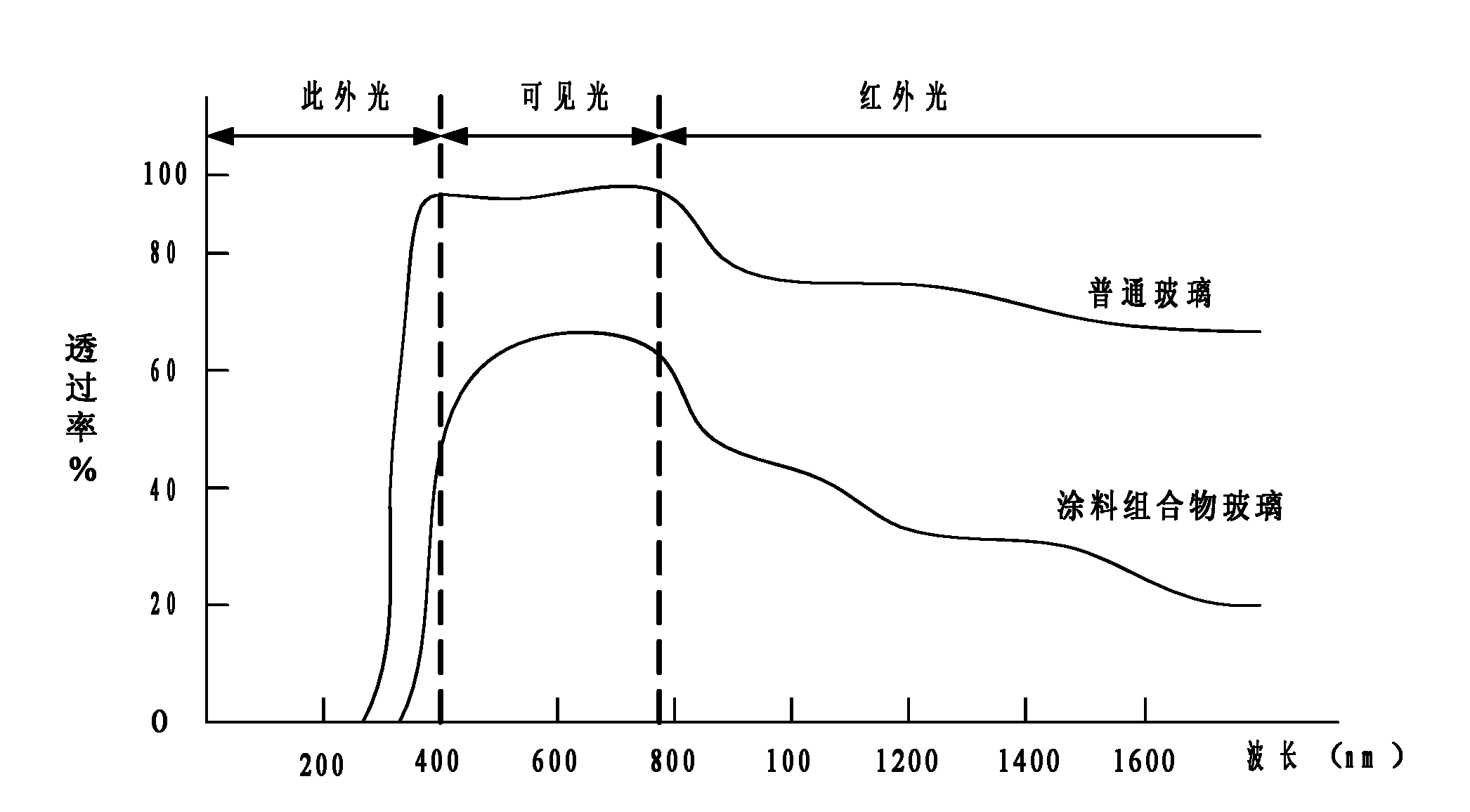

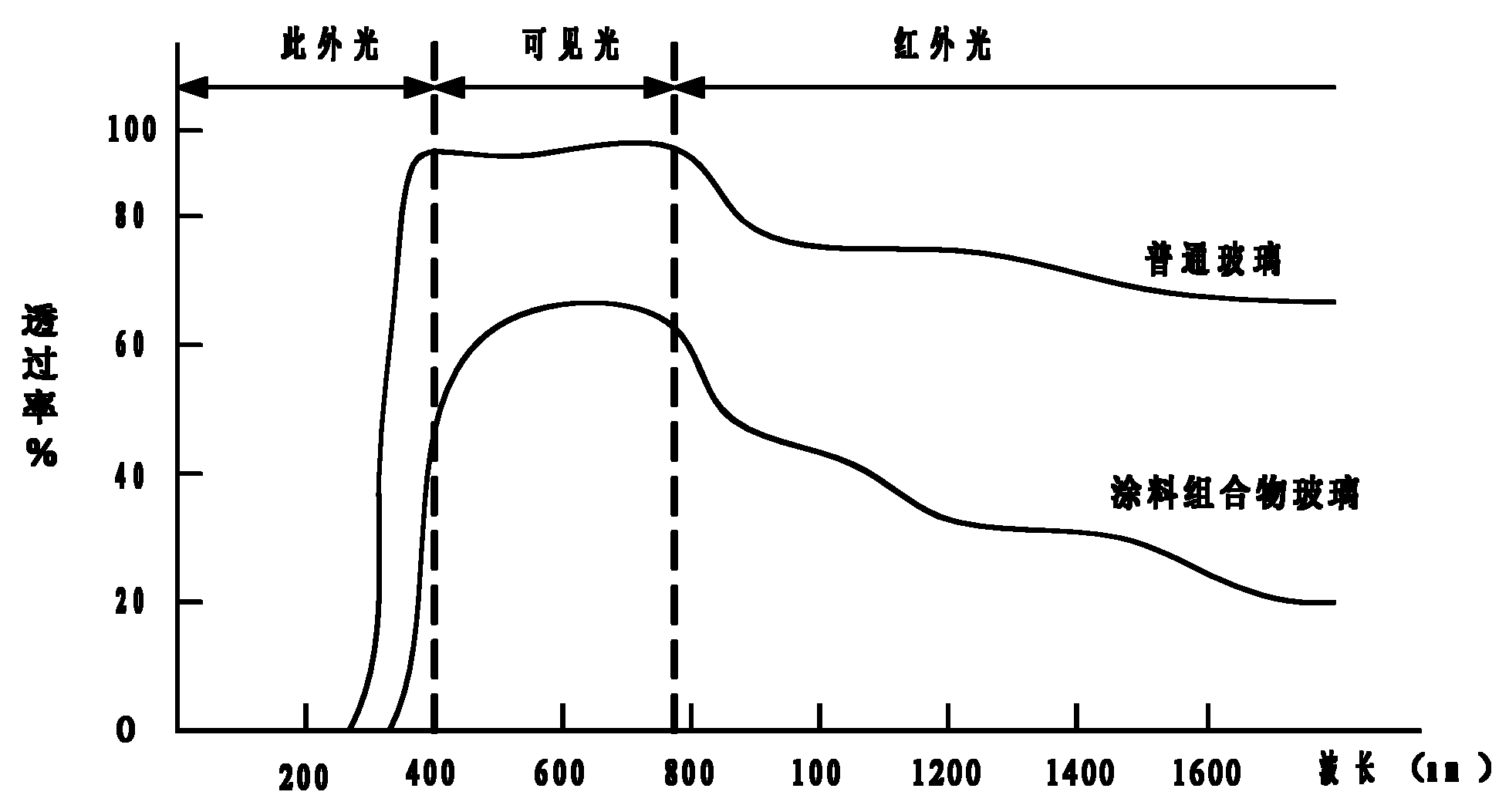

[0045] The coating composition for coating the glass surface prepared by the above method is water-based. After being coated on the glass surface, the reflectance of visible light is 200%, and the shading coefficient is 0.62. On the coated glass substrate, the thickness of th...

Embodiment 2

[0047] This embodiment is used for the preparation method of the coating composition of coating glass surface, comprises the following steps:

[0048] S1, preparing an alcoholic solvent consisting of 24% by mass of silicone resin, 36% by mass of ethanol, and 0.4% by mass of a defoamer;

[0049] S2, adding 39.6% quality nano slurry;

[0050] S3, mixing the nano slurry and the alcoholic solvent in steps S1 and S2.

[0051] The nano slurry includes 20% by mass of silicon dioxide, 15% by mass of indium tin oxide, 8% by mass of a wetting and dispersing agent, 6% by mass of a hyperdispersant, and 51% by mass of ethanol.

[0052] The coating composition for coating the glass surface prepared by the above method is alcoholic. After being coated on the glass surface, the reflectance of visible light is 22%, and the shading coefficient is 0.62. On the coated glass substrate, the thickness of the paint film is 10 microns, the reflectance of visible light is 15%, and the shading coeffic...

Embodiment 3

[0054] This embodiment is used for the preparation method of the coating composition of coating glass surface, comprises the following steps:

[0055] S1, preparing an oily solvent composed of 49% quality acrylic resin, 20% quality xylene, 0.5% quality leveling agent, and 0.5% quality defoamer;

[0056] S2, adding 30% quality nano slurry;

[0057] S3, mixing the oily solvent and nano slurry in steps S1 and S2.

[0058] The nano slurry includes 35% by mass of titanium nitride, 8% by mass of lanthanum hexaboride, 4% by mass of wetting and dispersing agent, 5% by mass of hyperdispersant, and 48% by mass of xylene.

[0059] The coating composition for coating glass surfaces prepared by the above method is oily. After being coated on the glass surface, the reflectance of visible light is 22%, and the shading coefficient is 0.62. On the coated glass substrate, the paint film thickness is 10 microns, the reflectance of visible light is 12%, and the shading coefficient is 0.50.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com