Self-adaptive control method and device for eliminating drifting of sensor

A technology of self-adaptive control and self-adaptive algorithm, applied in the direction of transmission control, special recording/indicating device, measuring device, etc., can solve the problems of poor safety and fuel consumption, different zero-point drift values, and zero-point drift changes, etc. Achieve strong self-adaptive ability, eliminate zero-point drift, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

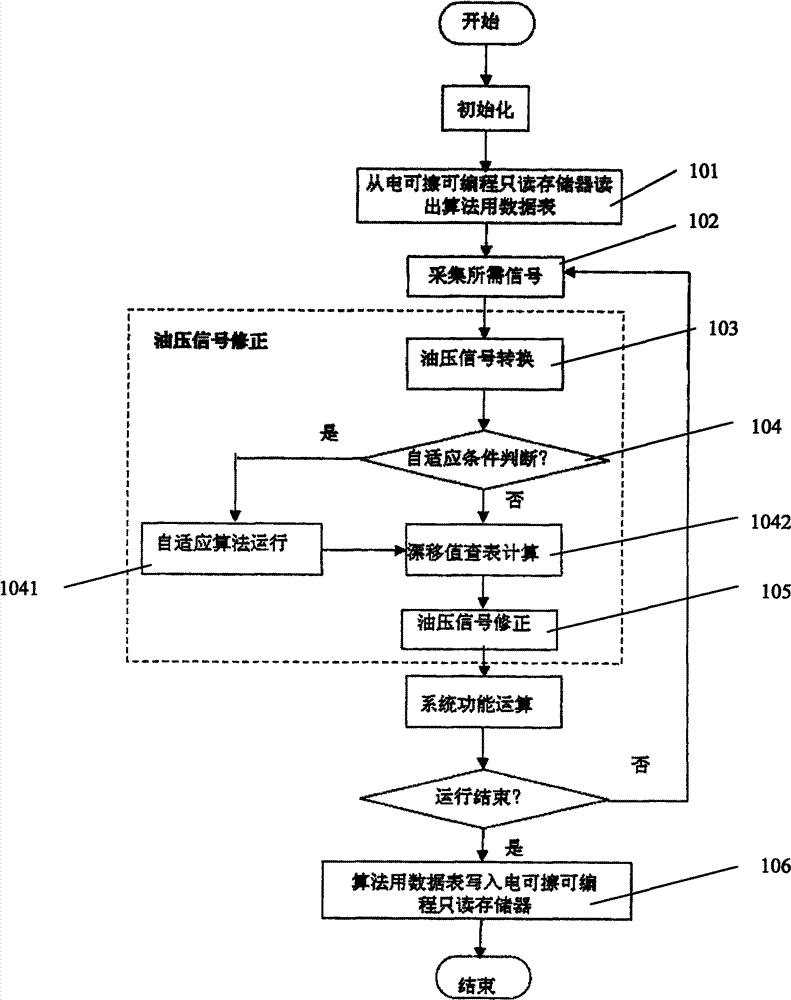

[0030] as attached figure 1 Shown, a kind of adaptive control method for eliminating sensor drift of the present invention is as follows:

[0031] 101. When the automatic transmission control unit (TCU) software is running, it first reads the data table for the adaptive algorithm into the random access memory (RAM), so as to update the data table after the algorithm runs.

[0032] This data table is the object modified by the adaptive algorithm. It is used to record and describe the characteristic curve of the zero point drift of the oil pressure sensor under different operating temperature conditions. The initial value of the data table is 0. After the working time of the vehicle is extended, Its data is constantly improving.

[0033] 102. The single-chip A / D module of the automatic transmission control unit (TCU) collects signals required for adaptive control such as oil pressure sensor signals (signals required for adaptive control include ignition valid signal, engine spe...

Embodiment 2

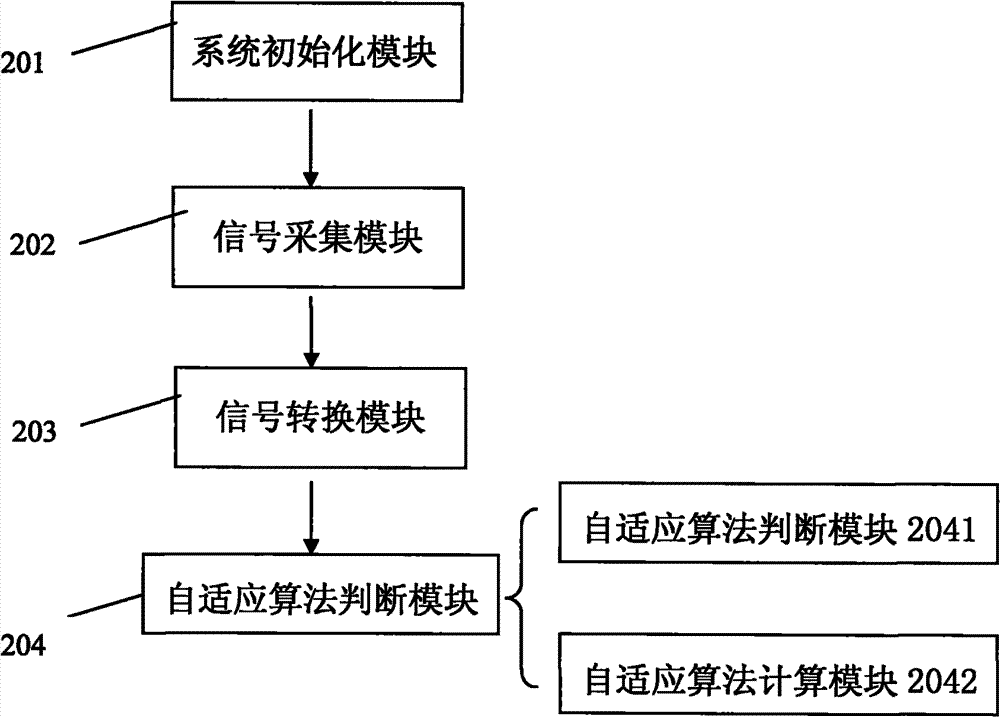

[0050] as attached image 3 As shown, an adaptive control device for eliminating sensor drift of the present invention includes a system initialization module 201, which is used to automatically read out a one-dimensional table data representing the relationship between oil temperature and sensor zero drift value when powered on, and It is stored in random access memory;

[0051] A signal acquisition module 202, configured to acquire signals required for adaptive control;

[0052] A signal conversion module 203, configured to convert the collected signals required for adaptive control into engineering units;

[0053] The adaptive algorithm working module 204 is used to determine whether the current working condition meets the operating conditions of the adaptive algorithm according to the collected signals required for adaptive control, and perform corresponding calculations to obtain the sensor zero drift value under the current working condition.

[0054]The device also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com