Electrostatic dry single-component electronegative toner for laser printer

A laser printer, one-component technology, applied in optics, electrical recording, instruments, etc., can solve the problems of image density, image adhesion and fixing firmness that plague toner manufacturers and poor versatility, and achieve excellent performance indicators and reduce Wasteful, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

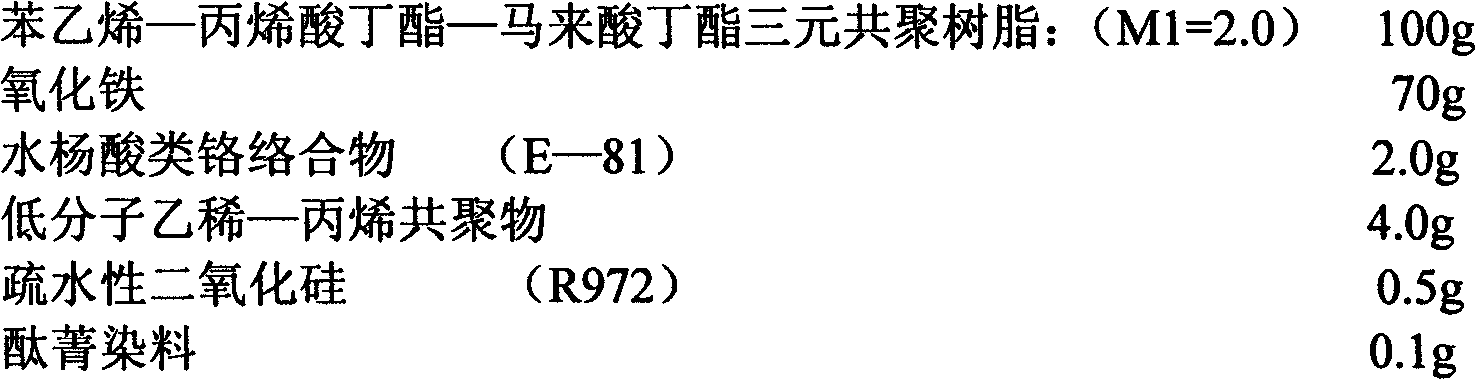

Embodiment 1

[0019]

[0020] After the above six kinds of raw materials are fully mixed with a high-speed mixer, they are mixed with an extrusion mixer, pressed into tablets, cooled, and then coarsely pulverized, finely pulverized, and then classified by wind to obtain a sub-extreme product with an average particle size of 11.2 μm. , add 0.7g of hydrophobic silicon dioxide treated with siloxane to this extreme product, and mix well to obtain high-quality toner. The image obtained by using this toner on the HP4300 printer has a high image density , High resolution, high image clarity, good fine lines and no sticking, good fixing firmness, and less wear on the photosensitive drum.

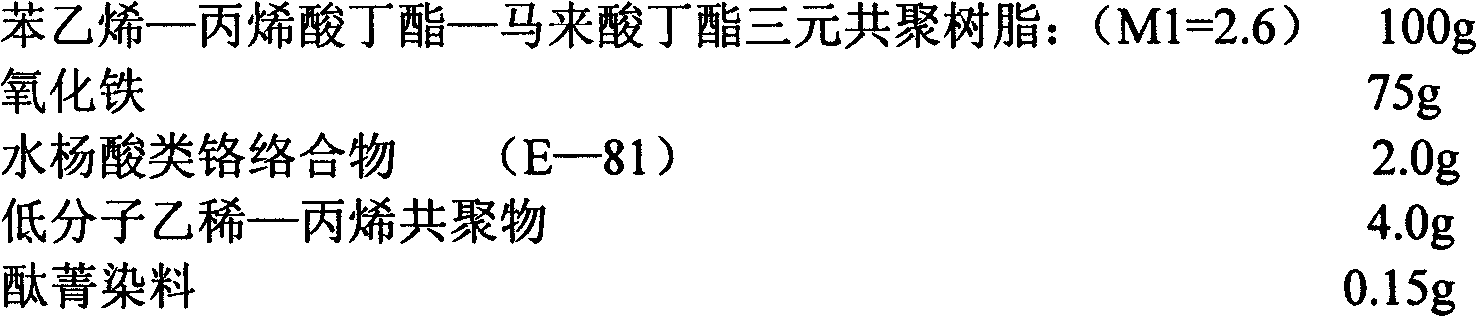

Embodiment 2

[0022]

[0023] The above-mentioned five kinds of raw materials are processed in the same way as Example 1, then add 0.72 of hydrophobic silicon dioxide treated with siloxane, and mix well. The image density of the image obtained by using the toner on the HP4300 printer is High, high resolution, high image definition, fine lines, good non-adhesion, good fixing firmness, and little wear on the photosensitive drum.

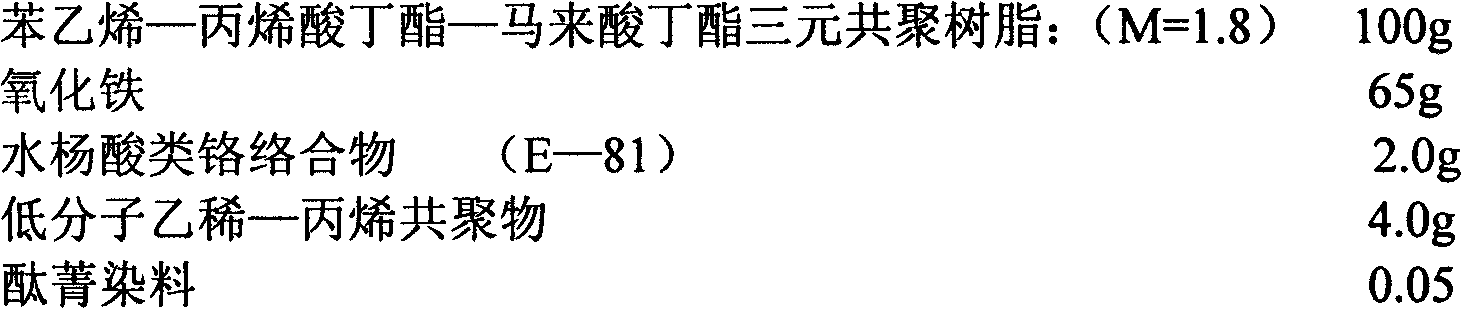

Embodiment 3

[0025]

[0026] The above five raw materials were processed in the same manner as in Example 1. After obtaining the graded toner, 0.68 g of siloxane-treated hydrophobic silica was added and mixed thoroughly. The image obtained by using the toner on the HP4300 printer has high image density, high resolution, high image definition, fine lines, good non-sticking, good fixation firmness, and little wear on the photosensitive drum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Loose density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com