Method for assembling rechargeable battery

A technology for rechargeable batteries and assembly methods, which is applied in the manufacture of alkaline storage batteries, battery pack parts, and alkaline storage batteries. Insufficient electrohydraulic volume, prevents pollution, and improves battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred specific embodiments.

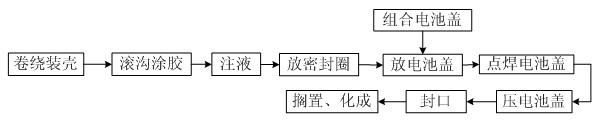

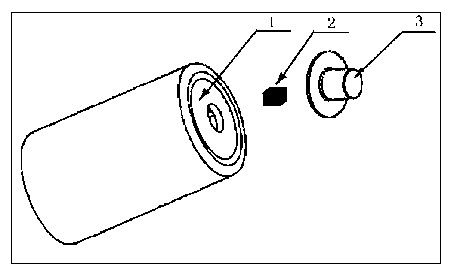

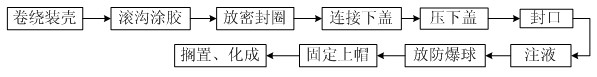

[0026] A method for assembling a rechargeable battery. The rechargeable battery includes a battery core, a steel shell, and a battery cover. The battery core includes a positive electrode, a negative electrode, and a diaphragm. The positive electrode is led out with tabs. The battery cover includes a lower cover, an explosion-proof The ball and the upper cap, the lower cover is provided with a hole, which includes the following steps in turn: 1) Winding and packing: winding the positive electrode, negative electrode and separator to form the battery core and loading it into the steel case; 2 ) Groove glue application: Roll the groove on the groove machine and apply glue to the mouth of the steel shell; 3) Put the sealing ring: Put the sealing ring on the battery core; 4) Connect the lower cover: Put the tab fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com