Quality assurance method by high-quality composite degradation of pesticide residues in orange peels

A pesticide residue, high-quality technology, applied in pharmaceutical formulations, food preparations, cosmetic preparations, etc., can solve the problems of ineffective pesticides, unstable light, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Pesticide Residue Degradation of Tangerine Peel in Xin'anjiang, Hangzhou

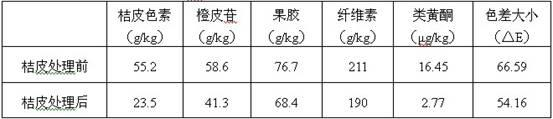

[0029] After peeling fresh Hangzhou Xin'anjiang real estate oranges, weigh about 4kg of orange peel, and prepare 5L Na 2 CO 3 Or NaOH solution (pH=11) and turn on the ozone generator, use a tube to introduce the generated ozone into the lye, the ozone concentration is 50mg / L, put the container containing the lye into the ultrasonic cleaner, and turn on the ultrasonic cleaner , where the ultrasonic intensity is 75W / cm 2 , frequency 20kHz, completely soak the orange peel in the lye, soak for 20min, and stir properly during the soaking process. After the composite immersion treatment is completed, transfer the orange peel to an ultrasonic cleaner filled with clean water, keep the ultrasonic intensity and frequency unchanged, soak in clean water for 5 minutes, and stir properly, at this time, mainly remove the decomposition of pesticides remaining on the surface of the orange peel Residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com