Method for using baffle reaction-rectification equipment for anti-disproportionation reaction of dichlorosilane and silicon tetrachloride

A technology of dichlorodihydrosilane and reactive distillation, which is applied in the direction of silicon halide compounds, chemical instruments and methods, fractionation, etc., can solve the problems of flammable and explosive, large amount of silicon tetrachloride to be treated, dichlorodihydrosilane Low boiling point and other issues, to achieve the effect of reducing energy consumption, increasing the utilization rate of raw materials, and increasing the total conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] The clapboard anti-disproportionation reaction rectification comprehensively utilizes 4000 tons / year of dichlorodihydrosilane and 6800 tons / year of silicon tetrachloride.

[0022] Composition of mixed chlorosilane raw materials: DCS:TCS:STC=1:1:1 (molar ratio). The feeding amount of mixed chlorosilane raw materials is 2t / h.

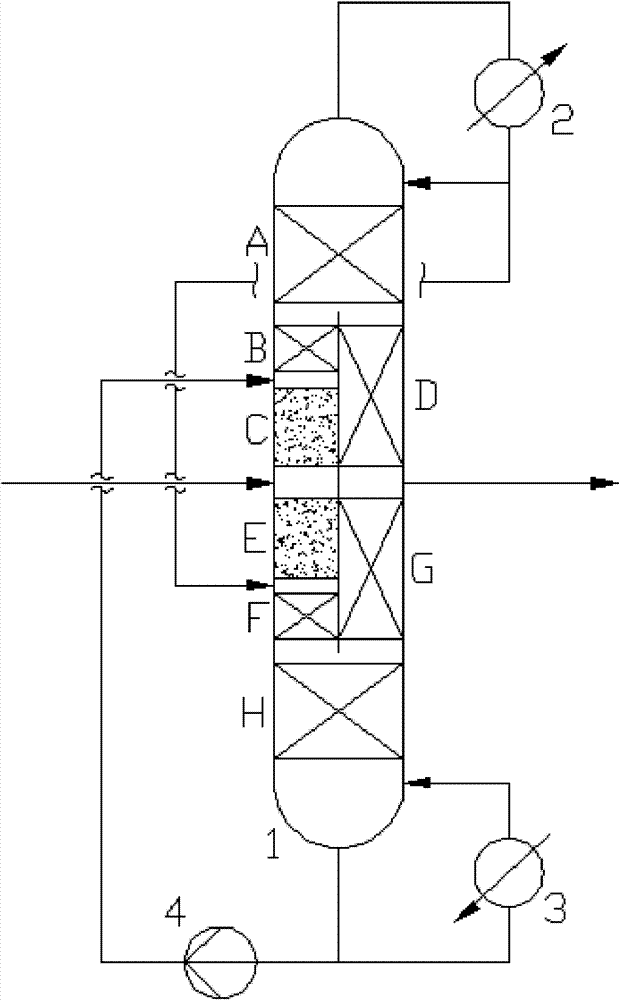

[0023] There are 6 theoretical plates in the A\H section of the clapboard reactive distillation column, 6 theoretical plates in the B\F section, 12 theoretical plates in the D\G section, and 2-meter-high reaction plates in the C\E sections. Catalyst, this example selects solid-loaded quaternary ammonium salt as reaction catalyst. The 2t / h mixed chlorosilane raw material enters the reaction pre-separation section in the middle of the C\E section. The operating pressure is 0.5MPa, the temperature at the top of the tower is 62°C, and the temperature at the bottom of the tower is 114°C. The liquid phase on both sides of the separator is evenly distr...

example 2

[0025] The clapboard anti-disproportionation reaction rectification comprehensively utilizes 4000 tons / year of dichlorodihydrosilane and 6800 tons / year of silicon tetrachloride.

[0026] Composition of mixed chlorosilane raw materials: DCS:TCS:STC=1:1:1 (molar ratio). The feeding amount of mixed chlorosilane raw materials is 2t / h.

[0027] There are 12 theoretical plates in the A\H section of the clapboard reactive distillation column, 12 theoretical plates in the B\F section, 24 theoretical plates in the D\G section, and four-meter-high reaction plates in the C\E sections. Catalyst, present example selects macroporous anion exchange resin as reaction catalyst for use. The 2t / h mixed chlorosilane raw material enters the reaction pre-separation section in the middle of the C\E section. The operating pressure is 0.2MPa, the temperature at the top of the tower is 30°C, and the temperature at the bottom of the tower is 75°C. The liquid phase on both sides of the separator is ev...

example 3

[0029] The clapboard anti-disproportionation reaction rectification comprehensively utilizes 4000 tons / year of dichlorodihydrosilane and 6800 tons / year of silicon tetrachloride.

[0030] Composition of mixed chlorosilane raw materials: DCS:TCS:STC=1:1:1 (molar ratio). The feeding amount of mixed chlorosilane raw materials is 2t / h.

[0031]There are 12 theoretical plates in the A\H section of the clapboard reactive distillation column, 12 theoretical plates in the B\F section, 24 theoretical plates in the D\G section, and four-meter-high reaction plates in the C\E sections. Catalyst, present example selects macroporous anion exchange resin as reaction catalyst for use. The 2t / h mixed chlorosilane raw material enters the reaction pre-separation section in the middle of the C\E section. The operating pressure is 0.3MPa, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 90°C. The liquid phase on both sides of the separator is eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com