Precise combined-machining equipment for complicated profiles made of hard and brittle materials

A complex profile, composite processing technology, applied in metal processing equipment, metal processing, metal processing mechanical parts, etc., can solve the problems of limited processing capacity, low processing efficiency, single processing method, etc., to eliminate processing errors, reduce The effect of machining cost, improving machining accuracy and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

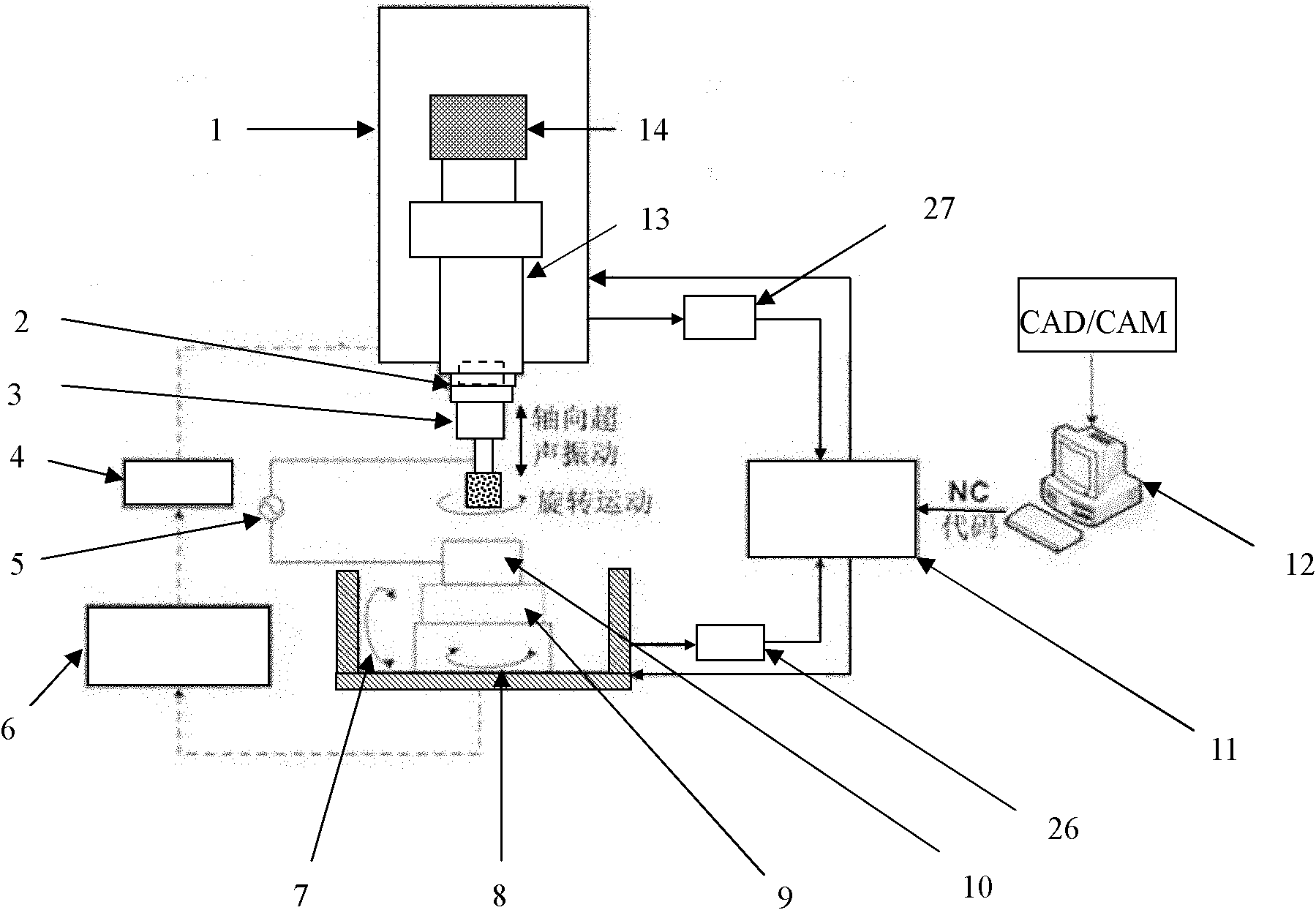

[0024] Adopt processing equipment of the present invention to carry out such as Figure 4 The ultra-precision machining of the workpiece shown in (a), the workpiece material is glass ceramics, the specific processing process is as follows:

[0025](1) Since the workpiece material is glass-ceramic, the compound processing method of ultrasonic-assisted grinding is used for processing this material. Using industrial computer programming to control the processing process;

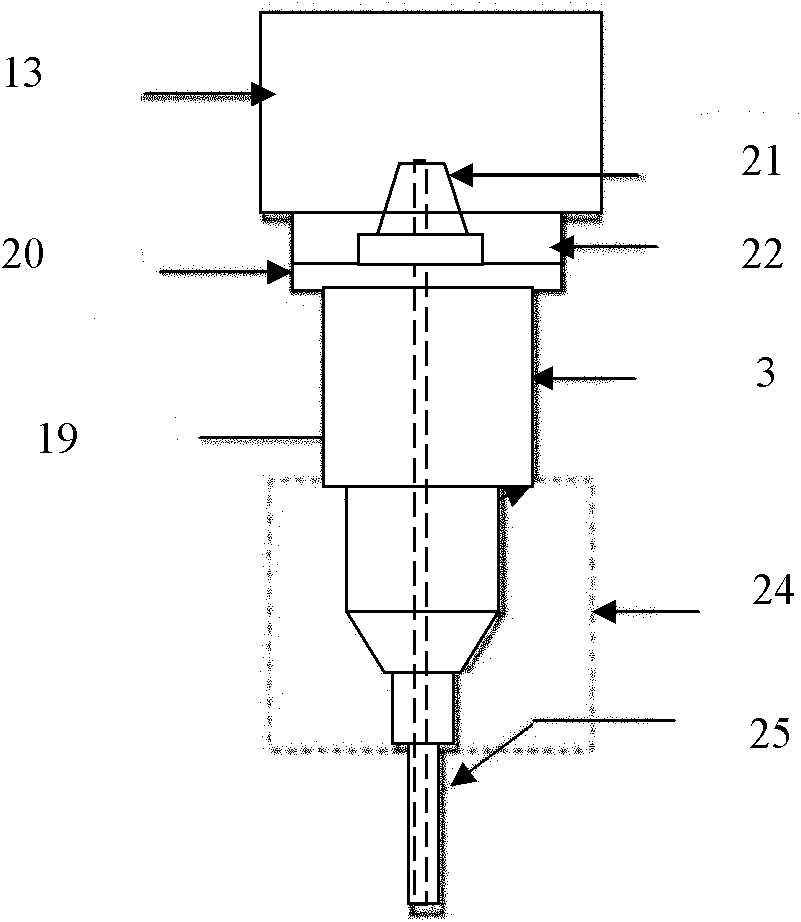

[0026] (2) First, rough machining the workpiece, select an electroformed diamond grinding head with a grain size of W120, and fix it on the front end of the spindle of the machine tool (such as image 3 shown).

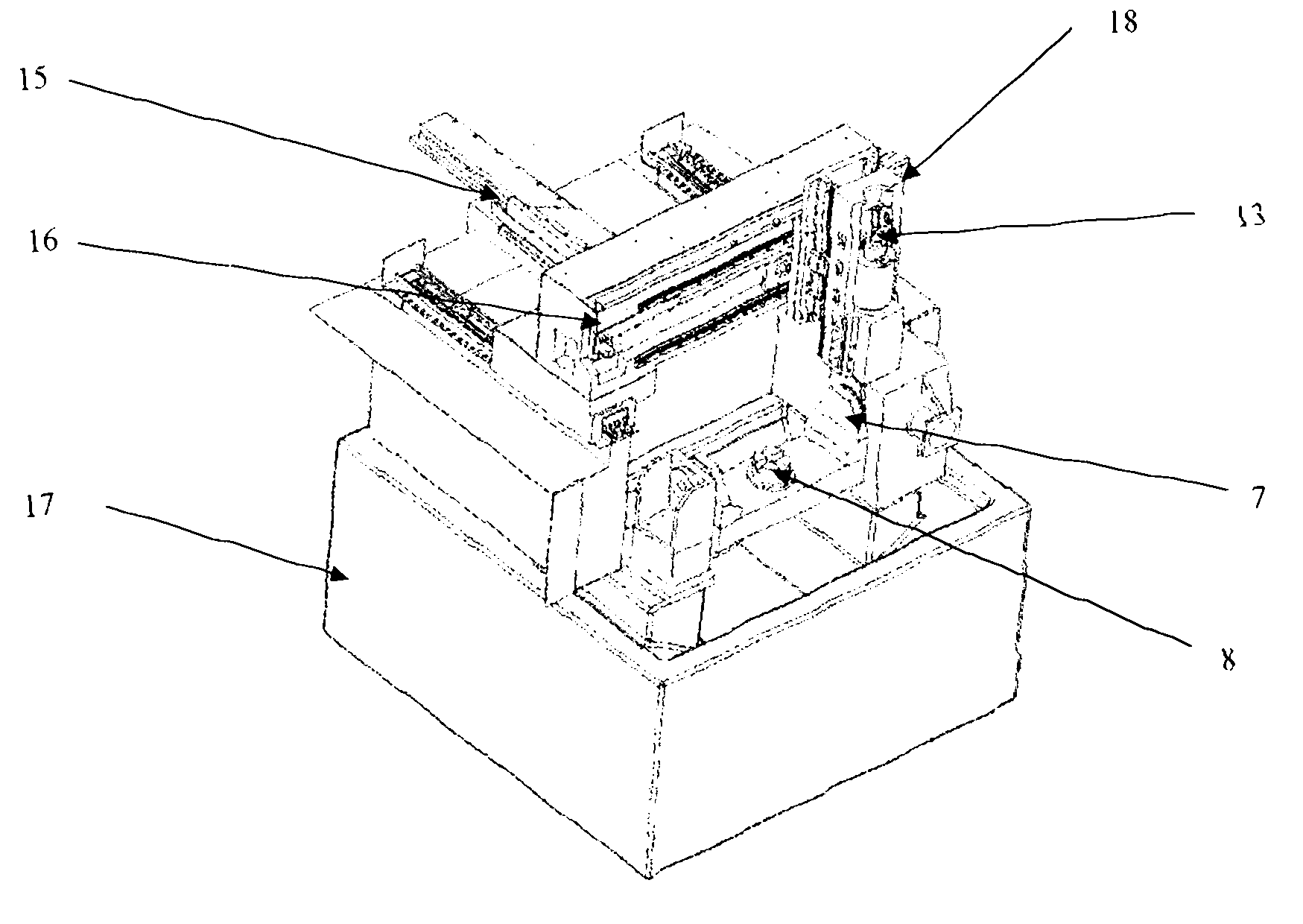

[0027] (3) Fix the unprocessed workpiece blank on figure 1 On the precision air flotation workbench shown (such as figure 1 shown).

[0028] (4) The processing parameters are set as: spindle speed 3000rpm, knife penetration 0.1mm, ultrasonic vibration frequency 25kHZ, cooling method water cooling,...

Embodiment 2

[0033] Carry out such as by processing equipment and processing method of the present invention Figure 4 The ultra-precision machining of the workpiece shown in (b), the workpiece material is hard alloy, the specific processing process is as follows:

[0034] (1) Since the workpiece material is cemented carbide, the composite processing method of ultrasonic-electric discharge-milling-grinding is used for processing this material. Using industrial computer programming to control the processing process;

[0035] (2) Fix the unprocessed workpiece blank on figure 1 On the precision air flotation workbench shown (such as figure 1 shown).

[0036] (3) Firstly, the workpiece is roughly machined, and the brass electrode is fixed on the tool handle at the front end of the spindle, and the electrode (+) and workpiece (-) are respectively connected to an external power supply (such as image 3 shown).

[0037] (4) The processing parameters are set as: EDM voltage 150V, pulse width / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com