Method for recovering oxalate and acid liquor from acidic etching waste liquor

A technology of acidic etching waste liquid and oxalate, which is applied in the field of recycling oxalate and acid liquid, can solve the problems of mountains and rivers and soil environmental pollution, and achieve the effect of eliminating procedures and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

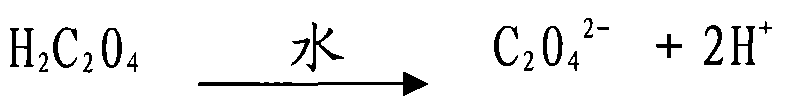

[0015] When the acidic etching waste liquid is a copper sulfate solution, oxalic acid is added to the copper sulfate solution to react to form a copper oxalate precipitate and a sulfuric acid solution. The chemical reaction formula is as follows:

[0016] CuSO 4 +H 2 C 2 o 4 →CuC 2 o 4 ↓+H 2 SO 4

[0017] The copper oxalate precipitate is separated from the acidic etching waste liquid by filtration or precipitation clarification to obtain solid copper oxalate. The copper sulfate waste liquid after extracting the copper ion components becomes a sulfuric acid solution with a higher concentration, which can be used as the raw material of the acid etchant in combination with the new liquid.

Embodiment 2

[0019] When the acidic etching waste liquid is a copper chloride solution, oxalic acid is added to the copper chloride solution to react to form a copper oxalate precipitate and a hydrochloric acid solution. The chemical reaction formula is as follows:

[0020] CuCl 2 +H 2 C 2 o 4 →CuC 2 o 4 ↓+2HCL

[0021] The copper oxalate precipitate is separated from the acid waste liquid by filtration or precipitation clarification to obtain solid copper oxalate. The waste copper chloride solution after extracting the copper ion components becomes a hydrochloric acid solution with a higher concentration, which can be used as a raw material for an acid etchant in conjunction with the new solution.

Embodiment 3

[0023] When the acidic etching waste liquid is a ferric chloride solution, oxalic acid is added to the ferric chloride solution, and the reaction forms a copper oxalate precipitate and contains iron ions (Fe 2+ ) and chloride ion Cl - Hydrochloric acid solution, its chemical reaction formula is as follows:

[0024] CuCl 2 +FeCl 3 +H 2 C 2 o 4 →CuC 2 o 4 ↓+Fe 2+ +3Cl - +2HCL

[0025] The copper oxalate precipitate is separated from the acidic etching waste liquid by filtration or precipitation clarification to obtain solid copper oxalate. The ferric chloride waste liquid after the copper ion component is extracted becomes acidity concentration higher and contains iron ion (Fe 2+ ) and chloride ion Cl - The hydrochloric acid solution can be used with the new solution as the raw material of the acid etchant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com