Preparing method for synthesizing sanmate from calcium cyanamide

A technology of lime nitrogen and carbendazim, which is applied in the field of preparation of carbendazim by using lime nitrogen, can solve the problems of low yield and excessive waste water, and achieve the effects of high waste water concentration, increased concentration, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

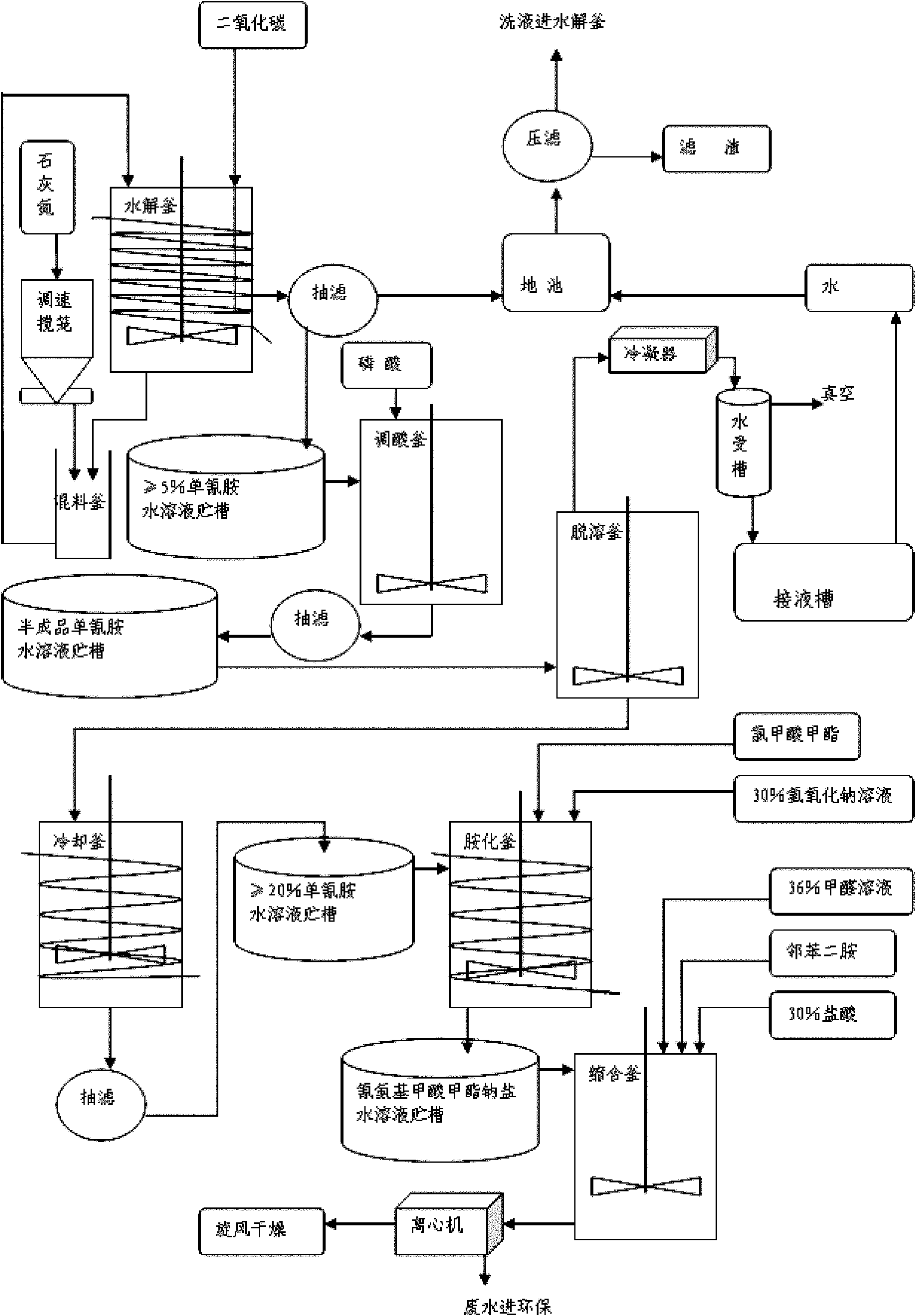

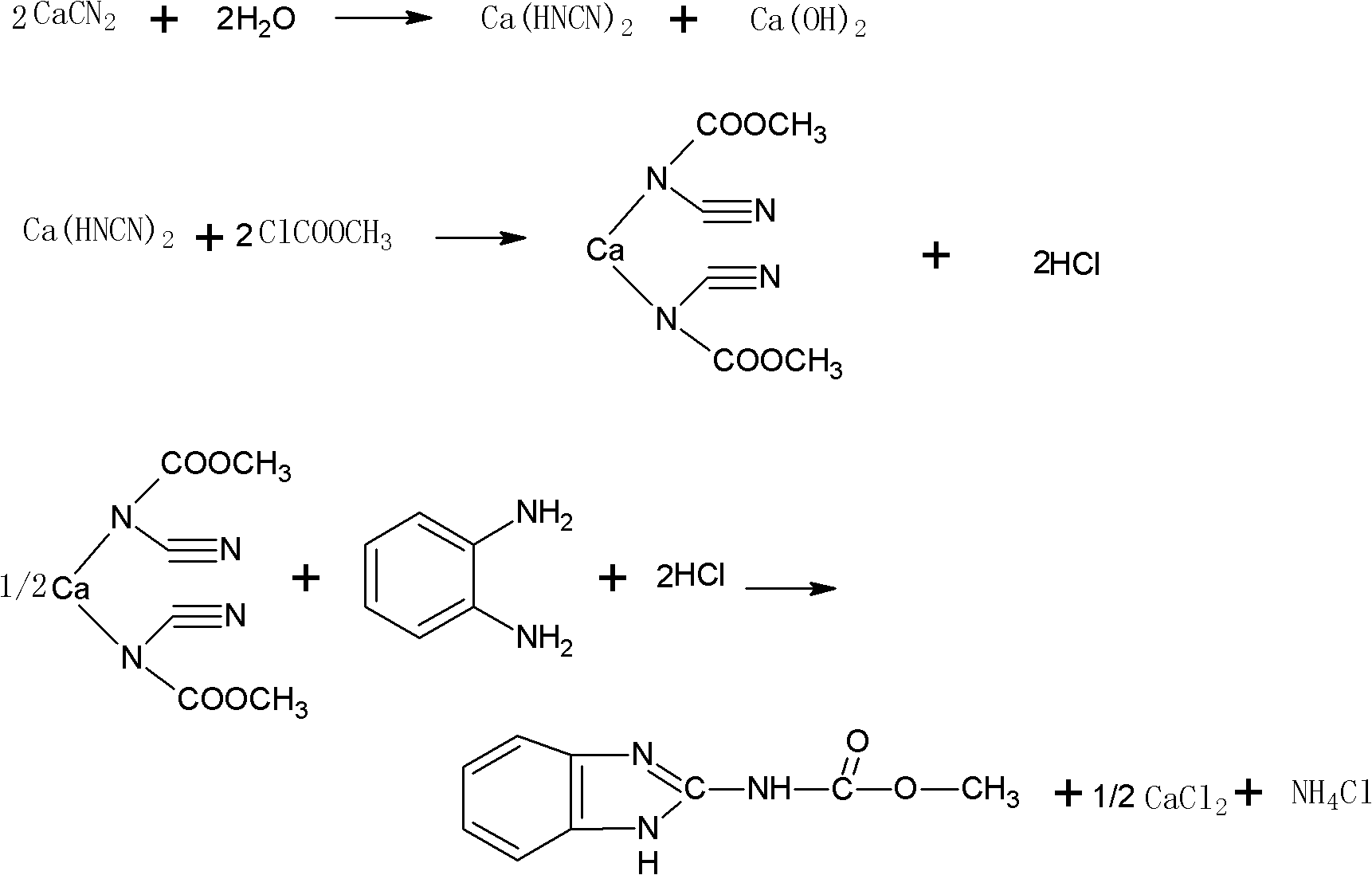

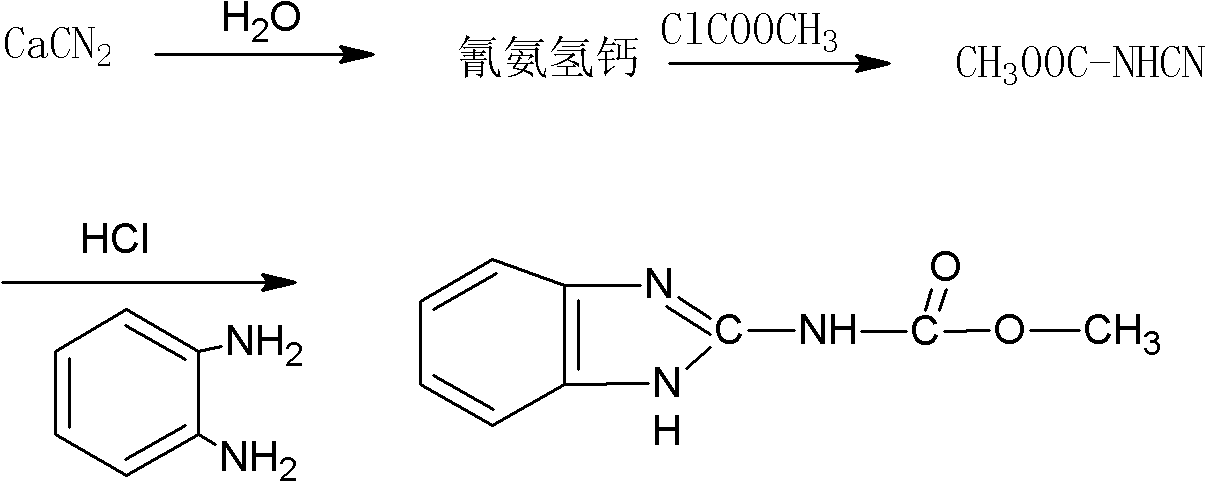

Method used

Image

Examples

Embodiment 1

[0062] 1) Put 1350ml of water or the last batch of washing liquid (need to make up if less than 1350ml) into a 2000ml four-necked bottle equipped with a thermometer, carbon dioxide ventilation device, condenser, and stirrer. The washing liquid is mentioned in step 3) below washing liquid;

[0063] 2) The temperature is controlled at 0°C, and 250g of lime nitrogen (effective nitrogen content 21%) is slowly added, and 82.5g of carbon dioxide gas is introduced during the feeding process to keep the pH value of the solution at 6;

[0064] 3) After feeding, vacuum filter, the filtrate is to adjust the pH value, wash the filter cake 4 times with 800ml of water, and collect the washing liquid to be used in the next batch of feeding;

[0065] 4) The filtrate is adjusted to pH 4 with an appropriate amount of 10% phosphoric acid, and then suction filtered to remove a small amount of solid impurities;

[0066] 5) The filtrate is concentrated in a rotary evaporator under reduced pressure...

Embodiment 2

[0072] 1) Put 500ml of water or the last batch of washing liquid (less than 500ml needs to be supplemented) into a 2000ml four-necked bottle equipped with a thermometer, carbon dioxide ventilation device, condenser, and stirrer. The washing liquid is mentioned in step 3) below. washing liquid;

[0073] 2) The temperature is controlled within the range of 50°C, and 250g of lime nitrogen (effective nitrogen content 21%) is slowly added, and 123.75g of carbon dioxide gas is introduced during the feeding process to keep the pH value of the solution at 9;

[0074] 3) After feeding, vacuum filter, the filtrate is to adjust the pH value, wash the filter cake with 500ml of water 4 times, and collect the washing liquid to be used in the next batch of feeding;

[0075] 4) The filtrate is adjusted to pH 6 with an appropriate amount of 80% phosphoric acid, and then suction filtered to remove a small amount of solid impurities;

[0076] 5) The filtrate is concentrated in a rotary evaporat...

Embodiment 3

[0082] 1) Put 800ml of water or the last batch of washing liquid (need to make up if less than 800ml) into a 2000ml four-necked bottle equipped with a thermometer, carbon dioxide ventilation device, condenser, and stirrer. The washing liquid is mentioned in step 3) below washing liquid;

[0083] 2) The temperature is controlled at 30°C, and 250g of lime nitrogen (effective nitrogen content 21%) is slowly added, and 91.67g of carbon dioxide gas is introduced during the feeding process to keep the pH value of the solution at 7;

[0084] 3) After feeding, vacuum filter, the filtrate is to adjust the pH value, wash the filter cake 4 times with 800ml of water, and collect the washing liquid to be used in the next batch of feeding;

[0085] 4) The filtrate is adjusted to a pH value of 5 with an appropriate amount of 60% phosphoric acid, and then suction filtered to remove a small amount of solid impurities;

[0086] 5) The filtrate is concentrated in a rotary evaporator under reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com