Cation polyacrylamide solution and application thereof as surface sizing assistant

A technology of polyacrylamide and acrylamide, which is applied in the direction of water-repellent addition, coating, paper coating, etc., can solve the problems of loss of reactivity, slow AKD sizing speed, and decrease of AKD utilization rate, so as to improve the utilization of energy The effect of improving the rate, improving the tensile index and shortening the molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare cationic polyacrylamide solution:

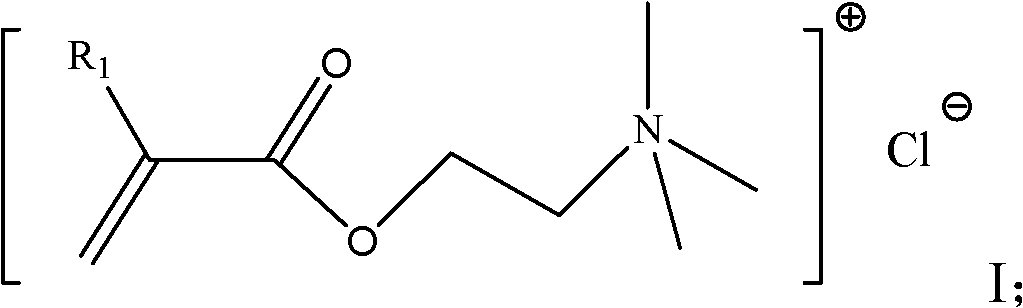

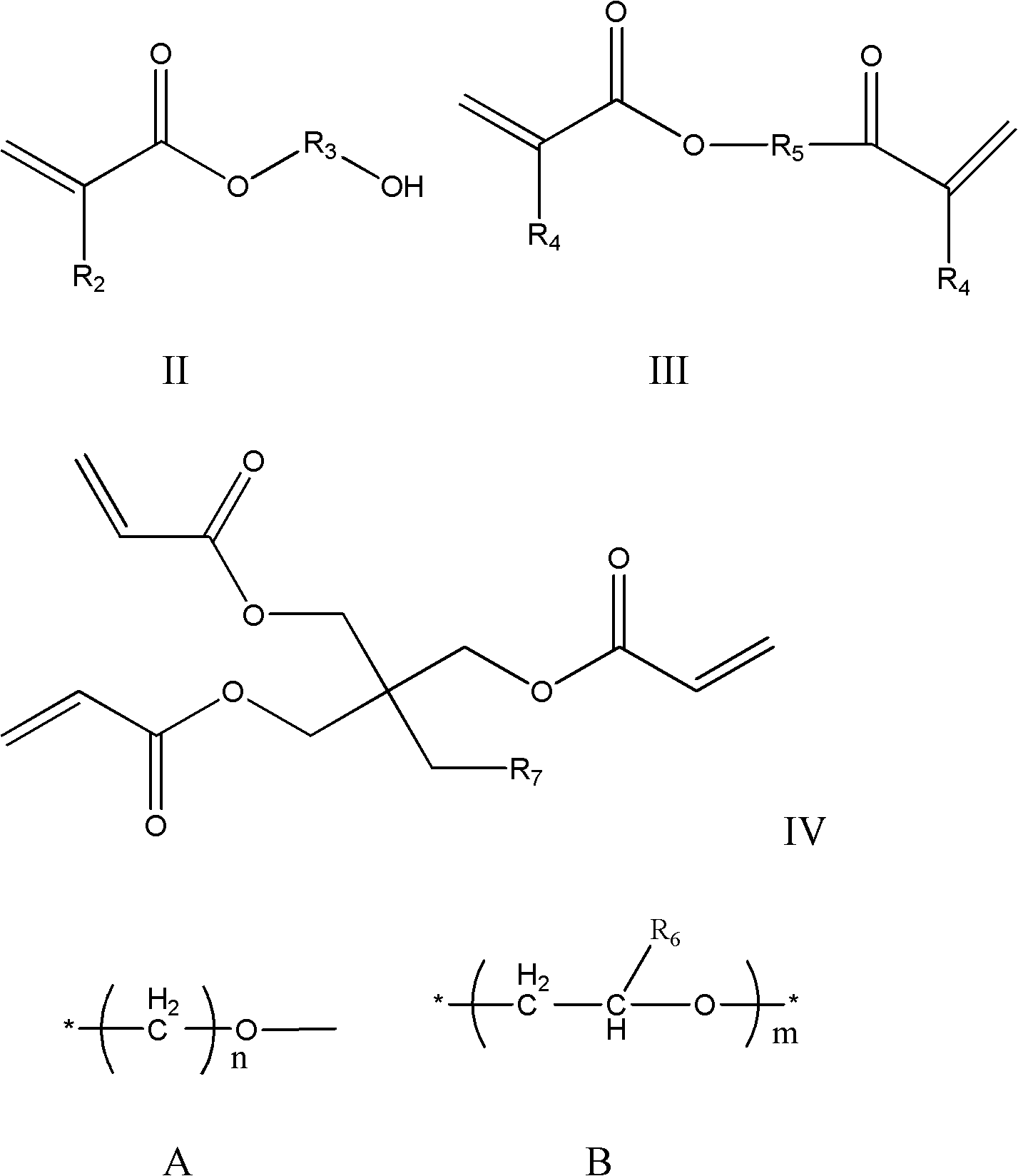

[0046] Raw material: 6.0g of acrylamide (98% purity, 0.0845mol), 2.27g of methacryloyloxyethyltrimethylammonium chloride (77.11% of solid content, 0.00845mol), 0.48g of hydroxyethyl methacrylate (0.0037mol), deionized water 150ml, absolute ethanol 5ml.

[0047] Steps: 6.0g of acrylamide (purity: 98%, 0.0845mol), 2.27g of methacryloxyethyltrimethylammonium chloride (solid content: 77.11%, 0.00845mol), 0.44% of hydroxyethyl methacrylate g (0.0037mol), be dissolved in the mixed solvent of 150mL deionized water and 5ml dehydrated ethanol, under nitrogen protection, stir at 30 ℃ temperature to obtain mixed solution, then stir 0.16g initiator (0.05g bisulfite Sodium, 0.11g ammonium persulfate) was added dropwise in the mixed solution, and after the dripping was completed, the reaction was incubated for 8 hours, and then cooled under stirring to obtain 160 g of cationic polyacrylamide solution, wherein the content of cationic polyac...

Embodiment 2

[0063] Raw materials: 6.0g of acrylamide (purity: 98%, 0.0845mol), 2.27g of methacryloxyethyltrimethylammonium chloride (solid content: 77.11%, 0.00845mol), 0.53g of hydroxypropyl methacrylate (0.0037mol), deionized water 150ml, absolute ethanol 5ml.

[0064] Steps: 6.0 g of acrylamide (purity 98%, 0.0845 mol), 2.27 g of methacryloxyethyltrimethylammonium chloride (solid content of 77.11%, 0.00845 mol), 0.53 hydroxypropyl methacrylate (0.0037mol), be dissolved in the mixed solvent of 150mL deionized water and 5ml dehydrated ethanol, under nitrogen protection, stir at 30 ℃ of temperature to obtain mixed solution, then stir with 0.16g initiator (0.05g sodium bisulfite , 0.11g ammonium persulfate) was added dropwise in the mixed solution, and after the drop was completed, it was incubated for 8 hours and then cooled under stirring to obtain 160 g of cationic polyacrylamide solution, wherein the content of cationic polyacrylamide was 5.1%.

[0065] Preparation of surface sizing a...

Embodiment 3

[0071] Raw materials: acrylamide 6.0g (purity 98%, 0.0845mol), methacryloxyethyltrimethylammonium chloride 4.00g (solid content 77.11%, 0.0193mol), 1,6-hexanediol Acrylate 0.30g (0.00133mol), deionized water 150ml, absolute ethanol 10ml.

[0072] Steps: 6.0g of acrylamide (purity: 98%, 0.0845mol), 4.00g of methacryloyloxyethyltrimethylammonium chloride (solid content: 77.11%, 0.0193mol), 1,6-hexanediol Diacrylate 0.30 (0.00133mol), dissolved in a mixed solvent of 150mL deionized water and 10ml absolute ethanol, under nitrogen protection, stirred at a temperature of 70°C to obtain a mixed solution, and then stirred 0.09g initiator (0.015g Sodium bisulfite, 0.075g of ammonium persulfate) was added dropwise in the mixed solution, and after the drop was completed, it was incubated for 2 hours and then cooled under stirring to obtain 168g of cationic polyacrylamide solution, wherein the content of cationic polyacrylamide was 5.6%. .

[0073] Preparation of surface sizing agent: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com