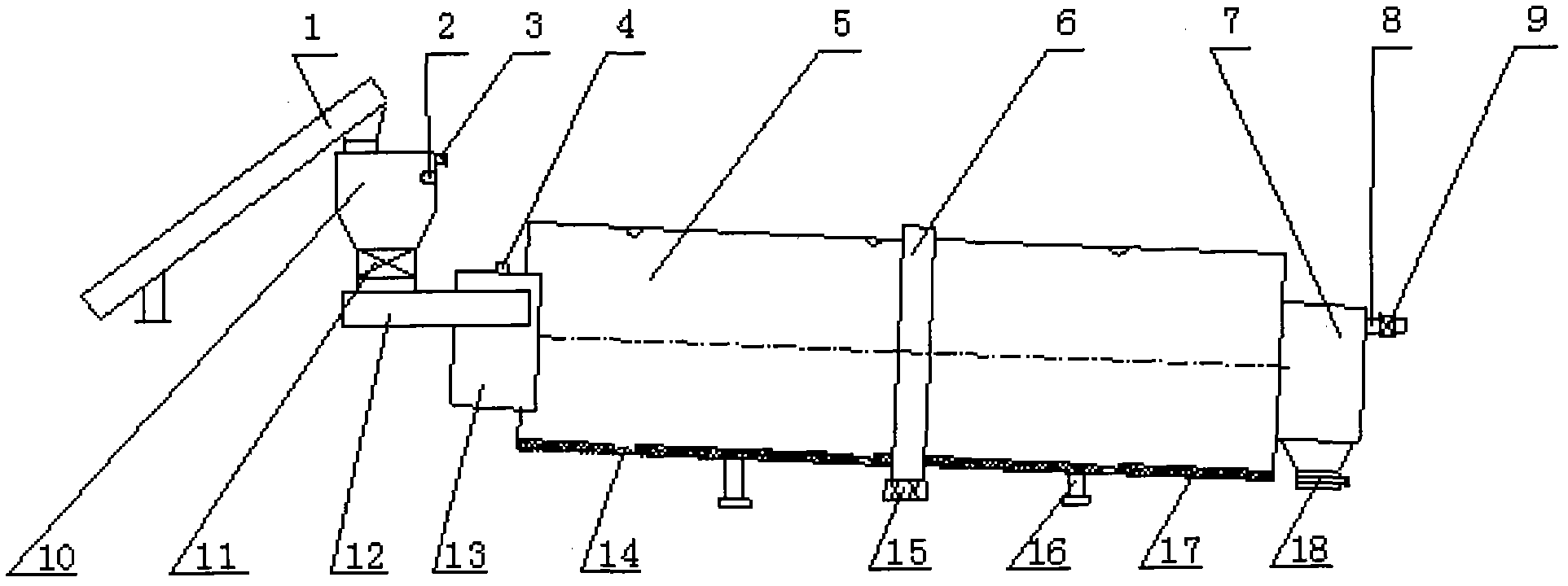

Continuous solid-state fermentation device for preparing fuel ethanol

A kind of solid state fermentation, fuel ethanol technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

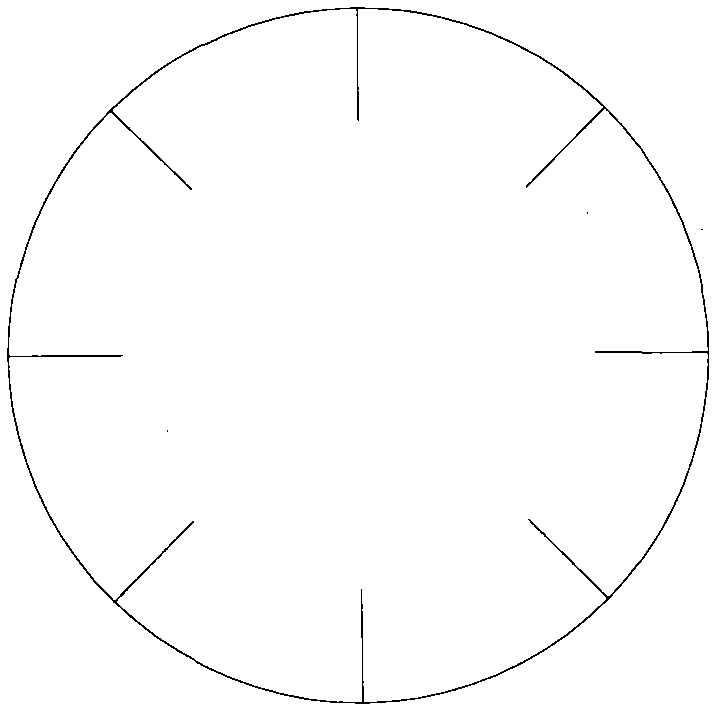

Method used

Image

Examples

Embodiment 1

[0033] Mature sweet sorghum stalks are harvested, and sweet sorghum stalks with a water content of 70%, a total sugar content of 11% and a reducing sugar content of 7% are used as raw materials and crushed into filaments with a diameter of 1-2 mm and a length of less than 30 mm. At the same time, TSH-Sc-001 strains are added into the closed silo, mixed with the pulverized material, and then continuously fermented in a continuous solid-state fermenter. The inoculation amount of the fermenting bacteria was 10% (V / W), and each operating parameter was adjusted to keep the temperature in the tank at 30-36° C., the fermentation time was 30 h, and the rotation speed of the fermenter was 0.25 rpm. After fermentation, the yield of ethanol is 92.2%, and the conversion rate of total sugar is 98.6%.

Embodiment 2

[0035]Mature sweet sorghum stalks are harvested, and sweet sorghum stalks with a water content of 70%, a total sugar content of 12% and a reducing sugar content of 8% are used as raw materials and crushed into filaments with a diameter of 1-2 mm and a length of less than 30 mm. At the same time, TSH-Sc-001 strains are added into the closed silo, mixed with the pulverized material, and then continuously fermented in a continuous solid-state fermenter. The inoculum amount of the fermenting bacteria was 10% (V / W), and each operating parameter was adjusted to keep the temperature in the tank at 30-36° C., the fermentation time was 36 hours, and the rotation speed of the fermenter was 0.1 rpm. After fermentation, the yield of ethanol is 94.1%, and the conversion rate of total sugar is 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com