Method for preparing compact nanocrystalline WC-Co hard alloy block material with small grain size

A technology of cemented carbide block and small grain, which is applied in the field of new materials and new powder metallurgy, to achieve the effect of small WC grain size, stable thermodynamic properties, and inhibition of WC grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

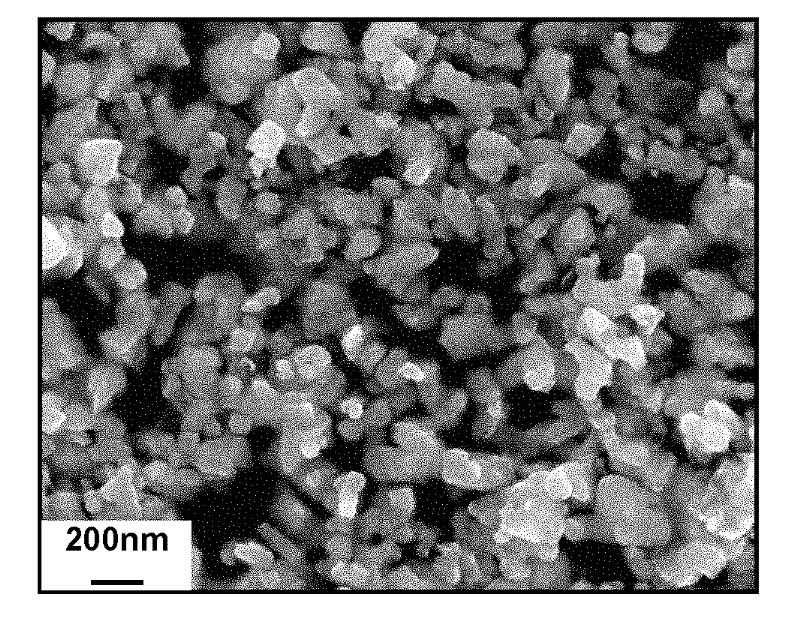

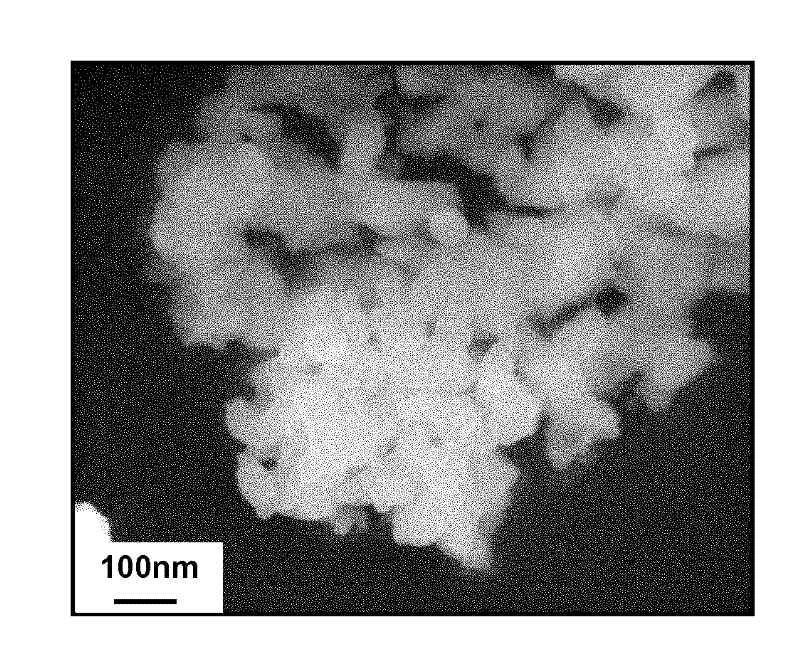

[0021] Firstly, the grain growth inhibitor VC powder particles are refined by ball milling. The ball milling process parameters are: ball-to-material ratio 5:1, ball milling time 50h, ball milling speed 600rpm, and the statistical average particle size of VC powder particles decreases after ball milling. to below 100nm; the VC powder particles after ball milling are 0.5% and the average particle diameter is the nanometer WC-Co composite powder of 90nm according to the total mass ratio of VC powder and WC-Co composite powder (microscopic appearance such as figure 1 ) for ball milling and mixing, the process parameters are: absolute ethanol is used as the liquid ball milling medium, the ball-to-material ratio is 1:1, the ball milling time is 20 hours, the ball milling speed is 600rpm, and the WC-Co-VC mixed powder after ball milling is put into 80°C vacuum drying Drying in the oven for 24 hours, the microscopic appearance of the prepared nano-WC-Co-VC mixed powder is as follows: ...

Embodiment 2

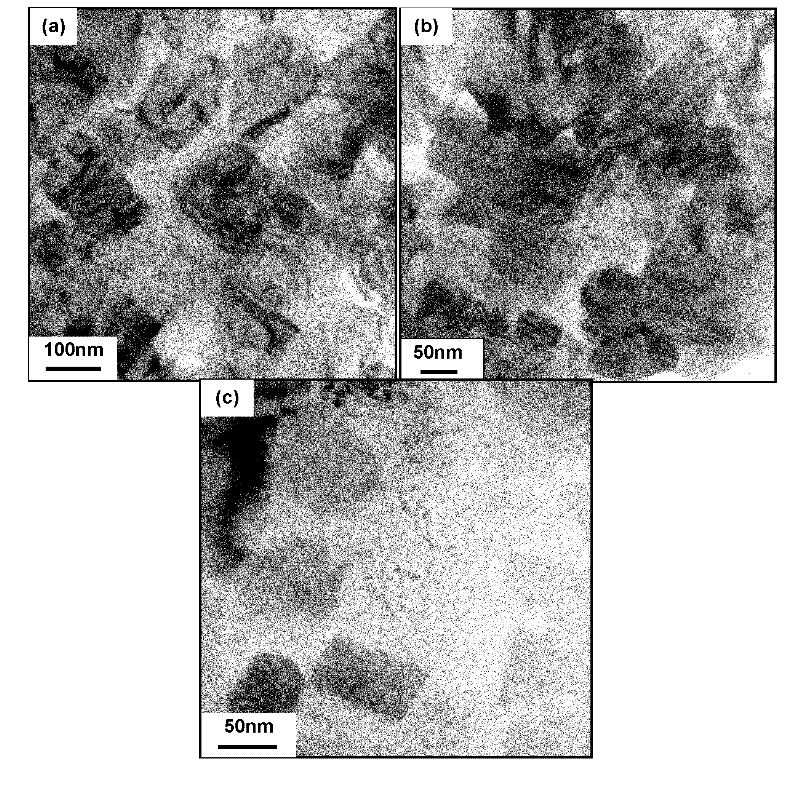

[0023] Firstly, the grain growth inhibitor VC powder particles are refined by ball milling. The ball milling process parameters are: ball-to-material ratio 20:1, ball milling time 20h, ball milling speed 300rpm, and the statistical average particle size of VC powder particles decreases after ball milling. to below 100nm; the VC powder particles after ball milling are mixed according to the total mass ratio of VC powder and WC-Co composite powder of 1.0% and nano-WC-Co composite powder with an average particle size of 70nm. The process parameters are: Anhydrous ethanol is used as the liquid ball milling medium, the ball-to-material ratio is 10:1, the ball milling time is 5 hours, the ball milling speed is 300rpm, and the WC-Co-VC mixed powder after ball milling is dried in a vacuum oven at 80°C for 12 hours; Sintering method The WC-Co-VC mixed powder is sintered and densified. The process parameters are: heating rate 200°C / min, after holding at 700°C for 1min, pressurizing 30MPa...

Embodiment 3

[0025] Firstly, the grain growth inhibitor VC powder particles are refined by ball milling. The ball milling process parameters are: ball-to-material ratio 10:1, ball milling time 30h, ball milling speed 500rpm, and the statistical average particle size of VC powder particles decreases after ball milling. to less than 100nm; the VC powder particles after ball milling are mixed according to the total mass ratio of VC powder and WC-Co composite powder of 2.0% and nano WC-Co composite powder with an average particle size of 60nm. The process parameters are: Anhydrous ethanol is used as the liquid ball milling medium, the ball-to-material ratio is 20:1, the ball milling time is 10 hours, the ball milling speed is 500rpm, and the WC-Co-VC mixed powder after ball milling is dried in a vacuum oven at 80°C for 20 hours; Sintering method The WC-Co-VC mixed powder is sintered and densified. The process parameters are: heating rate 300°C / min, after holding at 750°C for 3 minutes, pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com