Method and device for producing plant fiber straw mattress substrate

A plant fiber and production method technology, applied in the direction of wood processing equipment, pretreatment of molding materials, household components, etc., can solve the problems of waste, decreased stability, and increased wastewater treatment costs, etc., to reduce waste and facilitate loading and moving convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

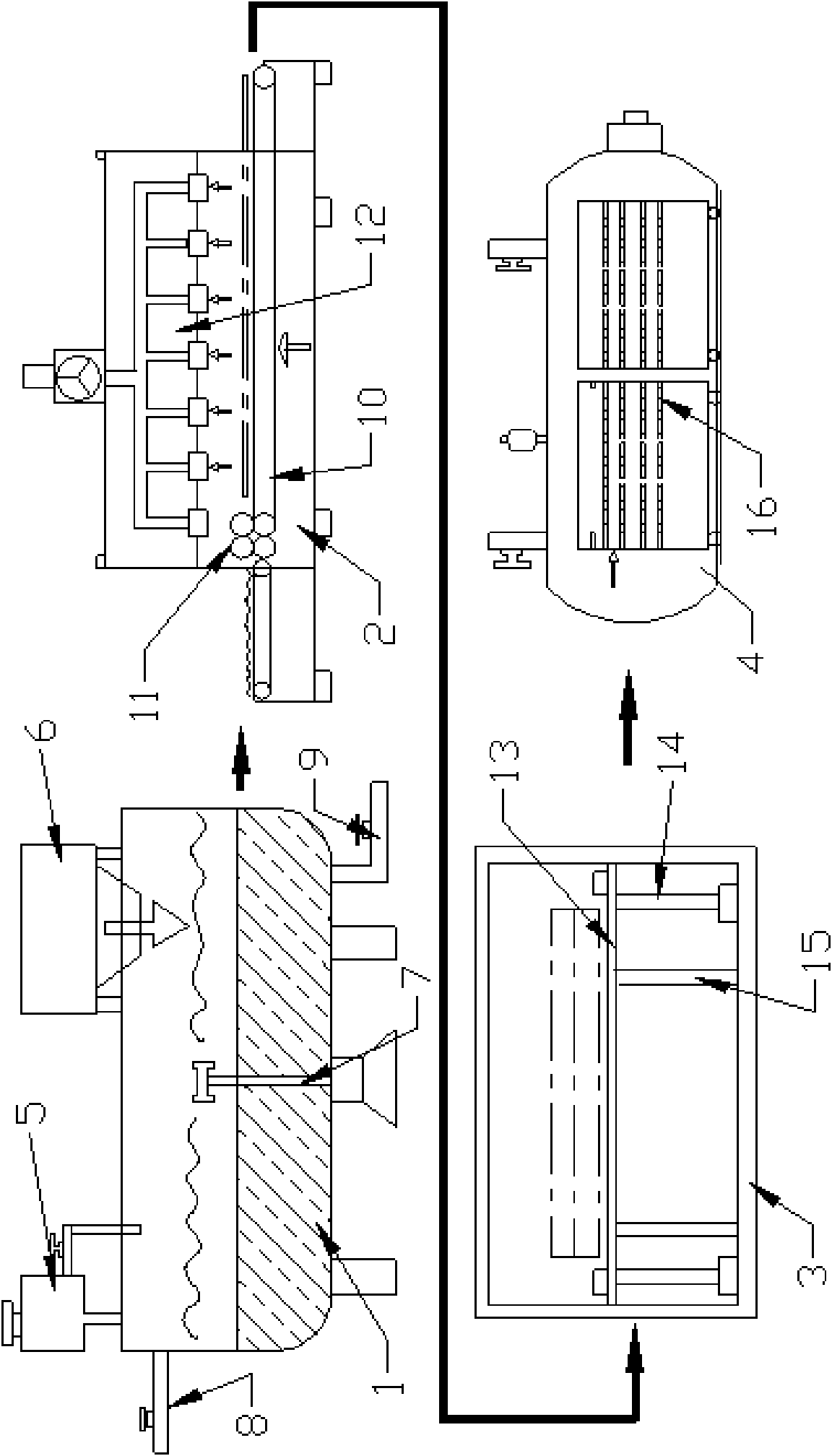

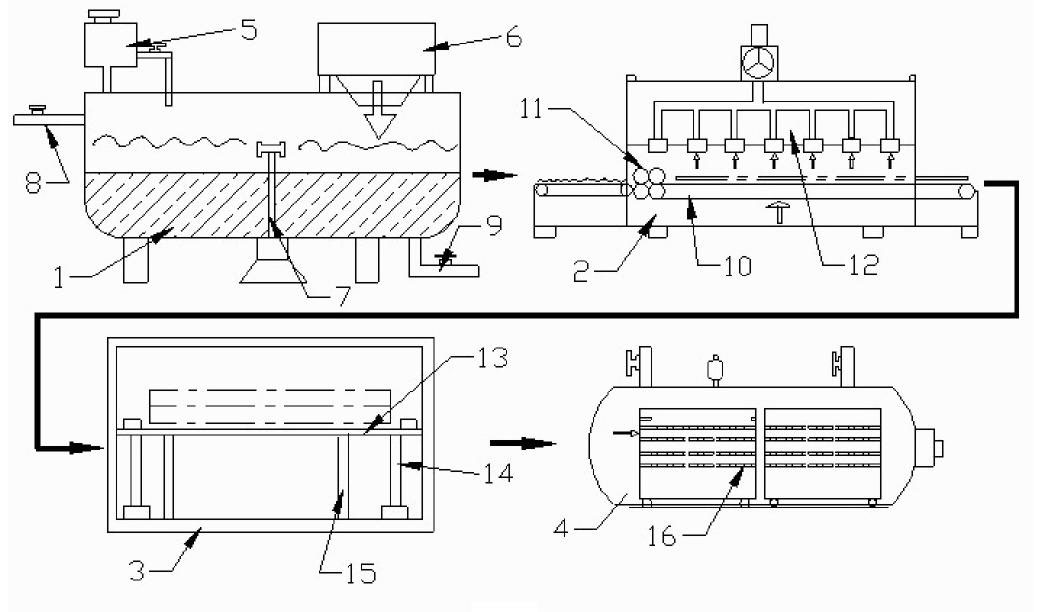

[0015] Embodiment 1 of the present invention: as figure 1 As shown, the device structure includes a settling tank 1 for settling latex waste liquid and plant fiber waste residue, a press dryer 2 for pressing and drying the sediment, and a hot press 3 for hot pressing and Vulcanized vulcanization tank4.

[0016] Install plant fiber adding device 6 and latex waste liquid delivery port 8 on settling tank 1, settling agent conveying box 5 is used to add settling agent, and stirring paddle 7 is installed in settling tank 1, latex waste liquid and plant fiber waste residue Stir evenly, set a discharge port 9 at the bottom of the settling tank 1, and discharge the raffinate.

[0017] The molding dryer 2 structure includes a conveyor belt 10 on which a roller 11 (roller) for molding is installed, and a drying device 12 is installed behind the roller 11 . The drying device 12 is composed of a hot air blower installed below the conveyor belt 10 , a hot air distribution plate, and a de...

Embodiment 2

[0023] Embodiment 2 of the present invention: device is identical with embodiment 1, and during settling, the settling agent that adopts is hydrochloric acid, polyacrylamide, and calcium nitrate, uses industrial hydrochloric acid to adjust the liquid pH value of settling tank to 6, by weight, Mix 1 part of polyacrylamide with 2 parts of calcium nitrate, add the mixture to the settling tank, and stir until gelation begins to appear in the settling tank, stop adding the settling agent.

[0024] After testing, the parameters of each section are as follows, and the effect is better: the drying temperature is kept at 80-100°C, and the moisture in the dried sheet is 14-16%. The temperature during hot pressing is 100-110°C. The vulcanization temperature is 110-115°C, the vulcanization time is 20-40 minutes, and the vulcanization pressure is 0.2-0.35MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com