Micro-electrolytic reactor

A micro-electrolysis reactor and micro-electrode technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of easy deposition of micro-electrode materials and reduce equipment operation and maintenance The effect of cost, reduction of stirring intensity, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

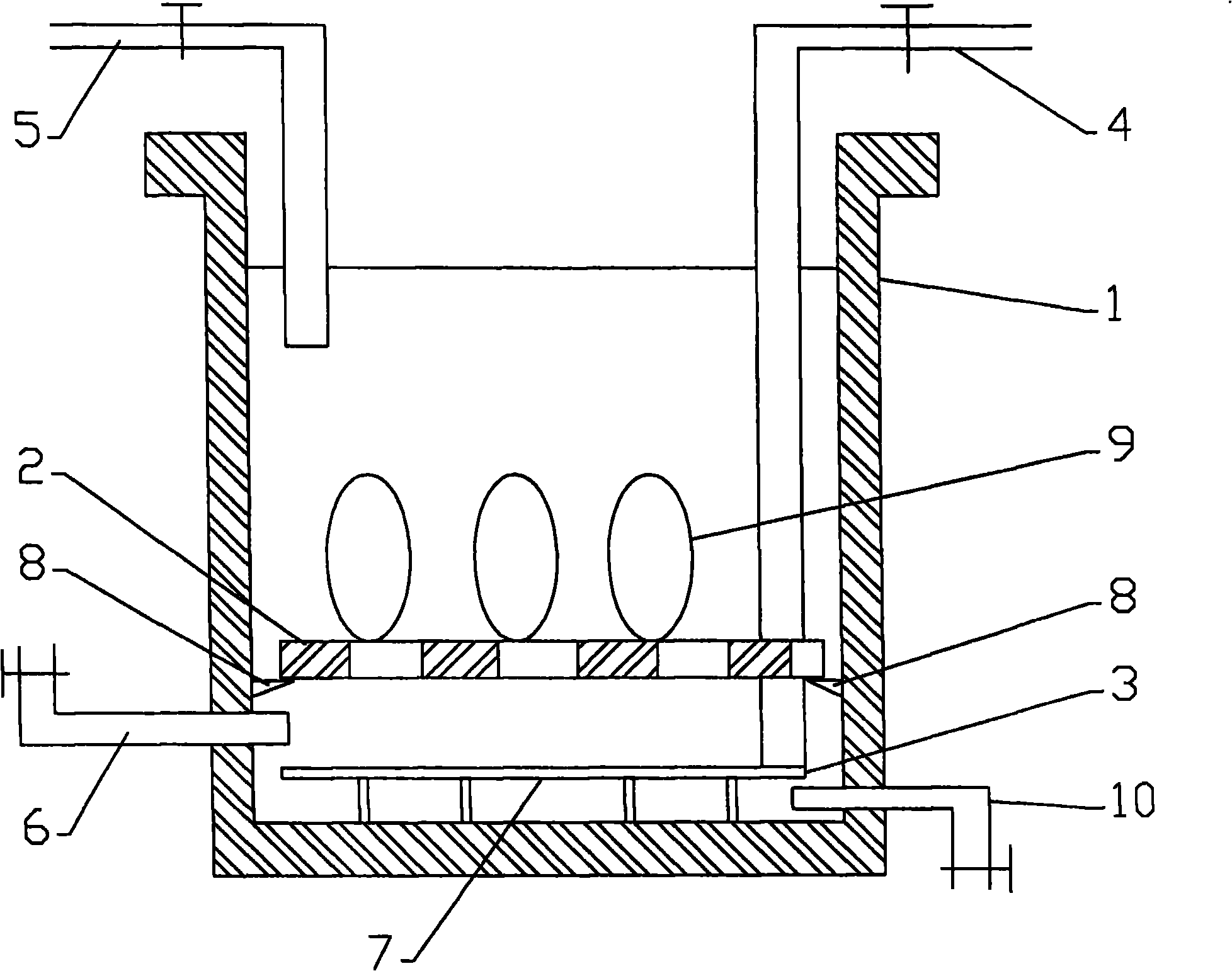

[0007] The present invention is based on the CN200910038783.1 invention patent of the designer of the present invention, and its gist is to use the lightweight microelectrode provided by this patent and provide auxiliary means to completely ensure that the lightweight microelectrode is not used in its use. Deposition, short circuit and other phenomena occur during the life time period. Invention patent CN200910038783.1 provides a microelectrode for waste water micro-electrolysis treatment composed of ceramsite, silicon dioxide, titanium dioxide, carbon powder and iron powder. The present invention will be described in further detail below in conjunction with the accompanying drawings.

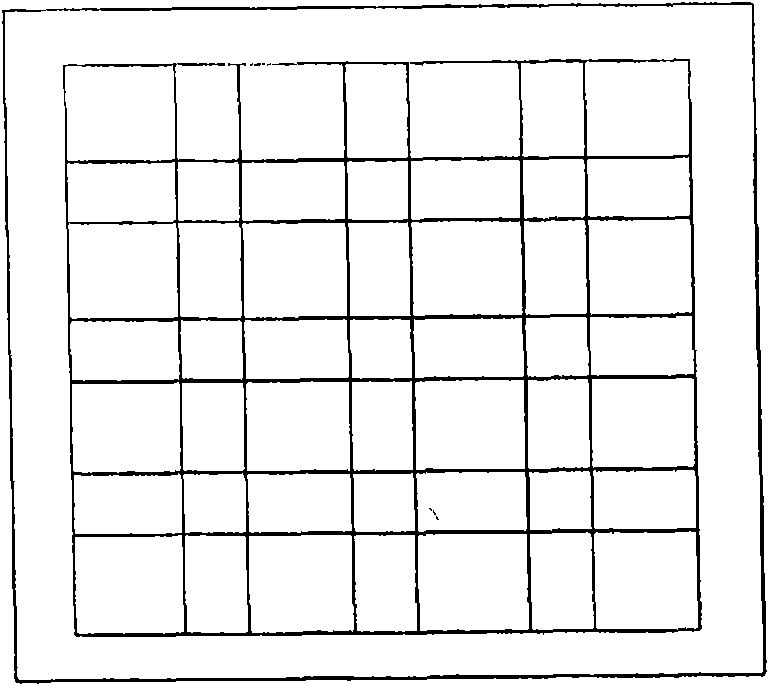

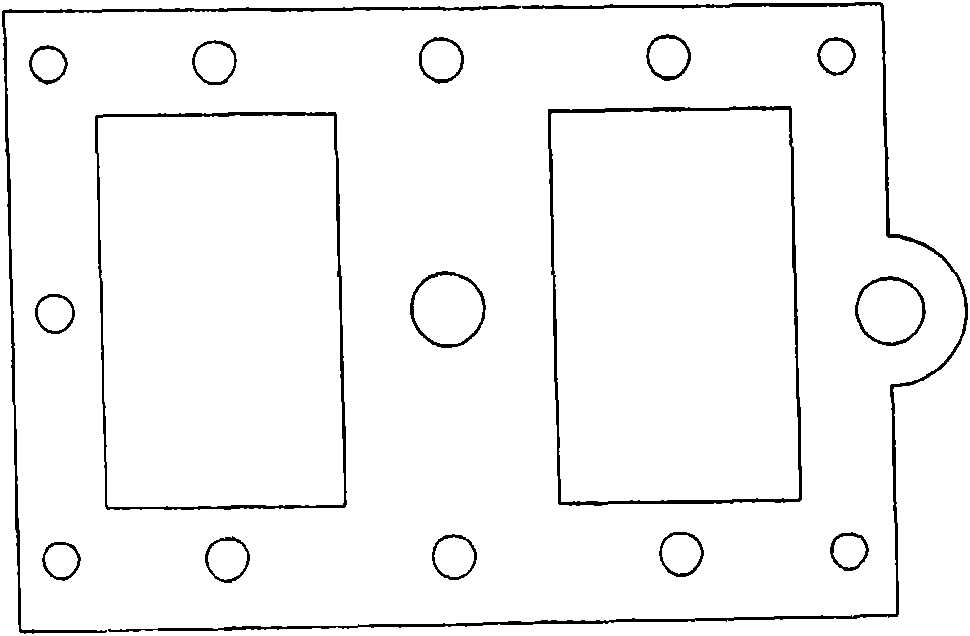

[0008] The invention discloses a micro-electrolysis reactor, comprising a waste water storage tank 1, the inner wall of the tank is coated with an acid-resistant and anti-corrosion paint layer, and a water outlet 6 for the treated clear water to flow out is provided at the lower part of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com