Regenerative coagulant, and preparation method and using method thereof

A coagulant and concrete technology, which is applied in the direction of sludge treatment through temperature control, flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high coagulant price, secondary pollution, The problem of limited landfill space and other issues can achieve the effect of improving the utilization rate of coagulant, reducing the cost of wastewater treatment, and achieving remarkable technological progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

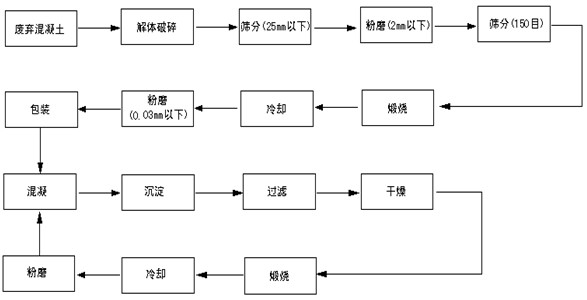

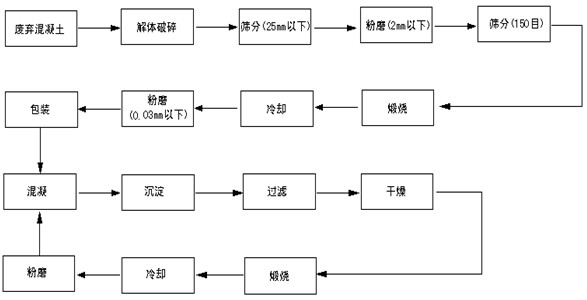

[0029] Such as figure 1 Shown is a schematic diagram of the process for the preparation and recycling of the new renewable coagulant proposed by the present invention. Collect waste concrete, remove sand and gravel, crush it to a particle size of less than 25 mm, and then use an autogenous mill to grind it to a particle size of less than 2 mm, pass through a 150-mesh sieve, and calcinate at 550°C for 2 hours, and then cool , using a high-pressure roller mill to grind to obtain a particle size of less than 0.03 mm and a specific surface area of 3000-4000 cm 2 / g of powder is the coagulant.

[0030] The simulated dye wastewater with hydrophobic disperse scarlet dye at a concentration of 0.15 g / L had an initial pH of about 8.0 and an absorbance of 1.41. It was treated with the above coagulant, first stirred at a high speed (200 r / min) for 30 min, then stirred at a slow speed (100 r / min) for 5 h, and finally settled for 30 min, and the supernatant was taken to measure the abso...

Embodiment 2

[0034]Collect the discarded concrete, remove the sand and gravel, first crush it to a particle size of less than 25 mm, then use an autogenous mill to grind it to a particle size of less than 2 mm, pass through a 150-mesh sieve, and calcinate at 600 °C for 2 h, after cooling , using a high-pressure roller mill to grind to obtain a particle size of less than 0.03 mm and a specific surface area of 3000-4000 cm 2 / g of powder is the coagulant.

[0035] The simulated dye wastewater with hydrophilic reactive brilliant blue dye at a concentration of 0.14 g / L had an initial pH of about 10.4 and an absorbance of 0.76. Treat it with the above coagulant, first stir it at a high speed (200 r / min) for 30 min, then adjust it at a slow speed (100 r / min) for 5 h, and finally settle it for 30 min, and take the supernatant to measure its absorbance and pH. Gradually increasing the dosage of coagulant, the coagulation dye removal rate increased accordingly, when the dosage of coagulant reach...

Embodiment 3

[0039] Collect the discarded concrete, remove the sand and gravel, first crush it to a particle size of less than 25 mm, then use an autogenous mill to grind it to a particle size of less than 2 mm, pass through a 150-mesh sieve, and calcinate at 650 ° C for 2 h, after cooling , using a high-pressure roller mill to grind to obtain a particle size of less than 0.03mm and a specific surface area of 3000-4000 cm 2 / g of powder is the coagulant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com