Coating liquid for preparation of high barrier milk packaging film as well as preparation method and application thereof

A technology of packaging film and coating liquid, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems affecting the application range of high-barrier layers, and achieve the effects of stable liquid viscosity, preservation of fragrance shelf life, and extended shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

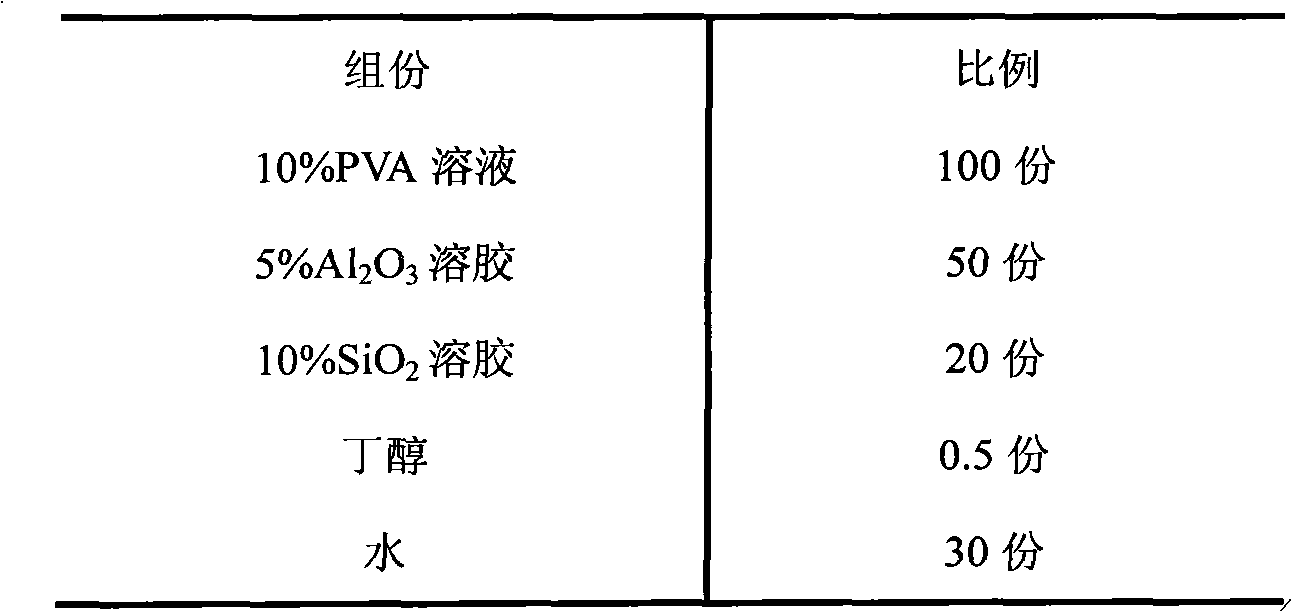

[0016] Table 1 The distribution ratio of each component of PVA high barrier coating liquid

[0017]

[0018] The proportion of PVA high-barrier coating solution is shown in Table 1. The preparation process is: add 0.5 parts of butanol to 100 parts of 10% PVA aqueous solution, stir well; then slowly add 50 parts of 5% Al under rapid stirring. 2 o 3 Sol, keep stirring for 2h; then slowly add 20 parts of 10% SiO 2 Sol, continue stirring for 0.5h; finally add 30 parts of water and stir evenly; the temperature in the whole process is controlled at about 25°C. The coating liquid obtained by the above method is a mixture.

[0019] Pour the above-mentioned high-barrier coating solution on a clean and flat stainless steel tray, place it in a vacuum oven at 45°C, and dry it. After the water is fully evaporated, place the film in an oven at 75°C for heat treatment for 2 hours, and peel it off to obtain Modified PVA film.

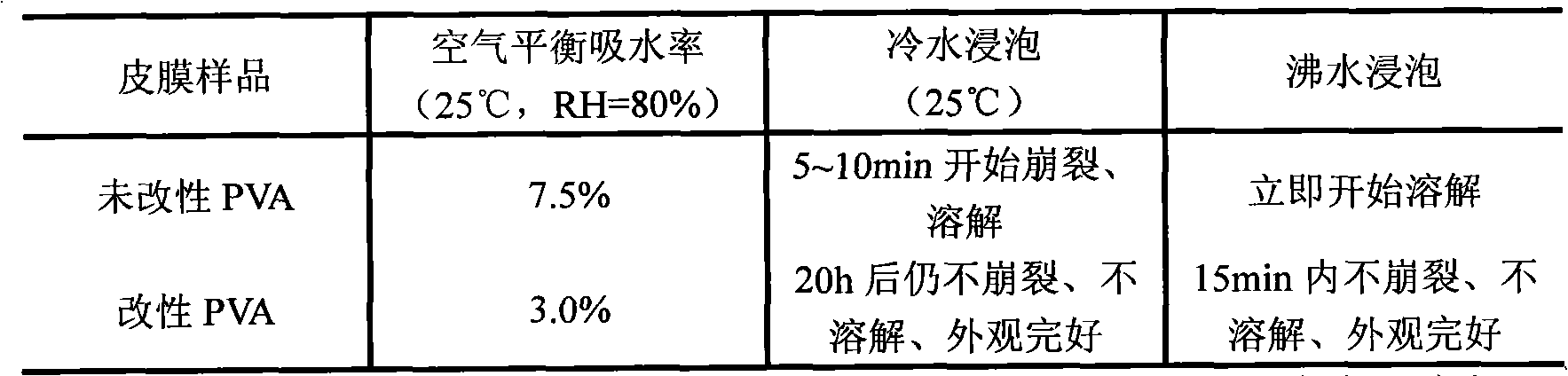

[0020] Table 2 Water resistance of modified PVA film

[0...

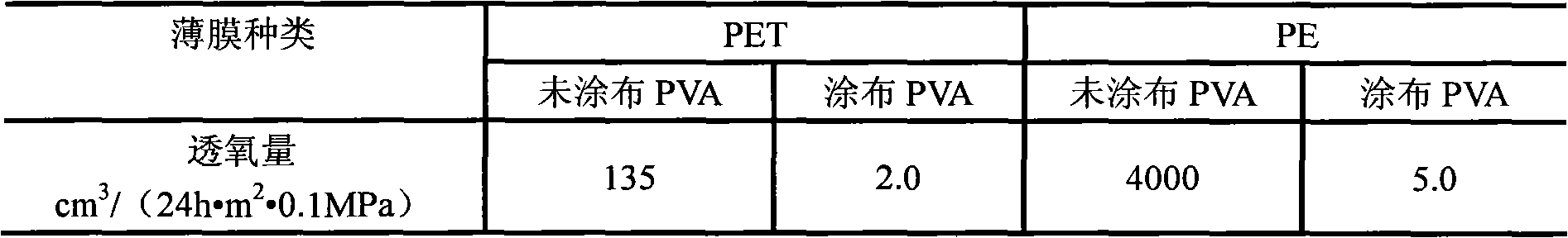

Embodiment 2

[0027] Table 4 The distribution ratio of each component of PVA high barrier coating solution

[0028]

[0029] The proportion of PVA high-barrier coating solution is shown in Table 4. The preparation process is: add 0.5 parts of butanol to 100 parts of 10% PVA aqueous solution, stir well; then slowly add 30 parts of 5% Al under rapid stirring. 2 o 3 Sol, keep stirring for 2h; then slowly add 20 parts of 10% SiO 2 Sol, continue to stir for 0.5h; finally add 50 parts of water and stir evenly; the temperature in the whole process is controlled at about 25°C.

[0030] Pour the above-mentioned high-barrier coating solution on a clean and flat stainless steel tray, place it in a vacuum oven at 45°C, and dry it. After the water is fully evaporated, place the film in an oven at 75°C for heat treatment for 2 hours, and peel it off to obtain Modified PVA film.

[0031] Table 5 Water resistance of modified PVA film

[0032]

[0033] After modification, the water resistance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com