Regenerating unit and method of diesel particle trap

A particle trap and regeneration device technology, applied in the direction of mufflers, exhaust devices, machines/engines, etc., can solve problems such as poor thermal conductivity, easy ablation of glow plugs, poor heating and evaporation of fuel oil, etc.

Inactive Publication Date: 2013-01-30

MILITARY TRANSPORTATION UNIV PLA

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) The heating capacity is limited and the heating temperature control is difficult

The exhaust gas heated by the burner is greatly affected by the change of engine working conditions. Generally, it can only complete the heating requirements under the conditions of shutdown, idle speed or low-speed stability. Under high-speed and heavy-load conditions, the heating capacity is insufficient and the regeneration time is long. At the same time, Under all working conditions, the exhaust temperature is constantly changing, the oxygen content in the exhaust is constantly changing, and it is difficult to control the heating temperature

[0006] (2) Poor uniformity of regeneration temperature field

[0007] (3) Larger exhaust resistance

Part of the structure of the burner is installed in the center of the exhaust pipe, which affects the exhaust flow. When the engine is working, the exhaust resistance is increased, the power is reduced and the fuel consumption is increased.

[0008] (4) Insufficient fuel combustion and poor emission during regeneration

The heating and evaporation effect of fuel oil is poor, and the connection between oil vapor and oxygen is insufficient, resulting in insufficient combustion, low combustion temperature, and increased HC and soot emissions during the regeneration process

[0009] (5) Large fuel consumption and long regeneration heating time

DPF has a large specific heat capacity and poor thermal conductivity. During the regeneration process, a large amount of heat from fuel combustion is directly taken away by the exhaust gas and discharged into the atmosphere. The DPF bed temperature increases slowly and the heating time is long

[0010] (6) The glow plug is easy to ablate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0068] Experimental research was carried out on the Beiqi Foton Aumark automobile engine. The main technical parameters of the diesel engine are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

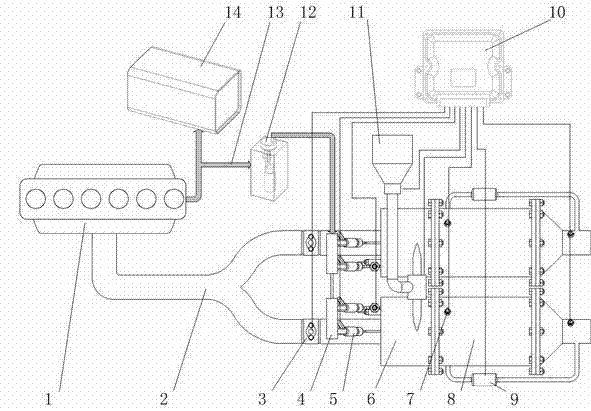

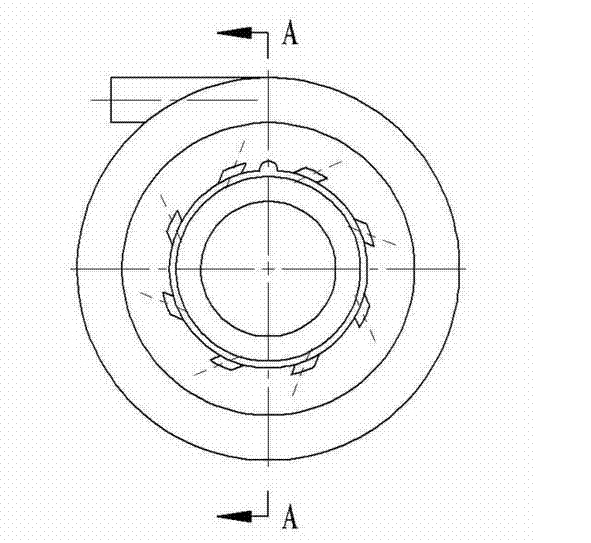

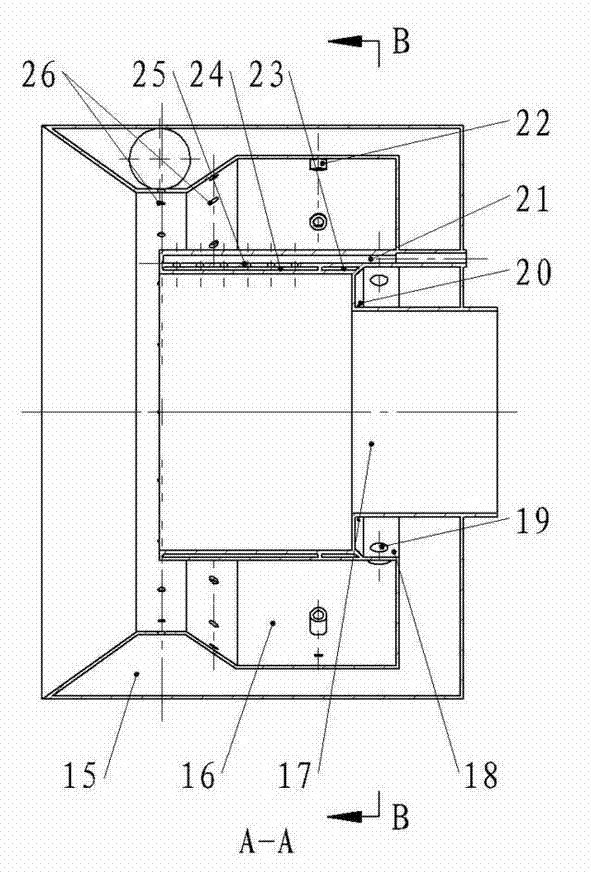

The invention discloses a regenerating unit and method of a self-evaporating diesel particle trap with the advantages of fuel and steam premixing and swirling flow combustion. The regenerating device of the diesel particle trap is arranged in the middle of an exhaust pipeline of a diesel powered vehicle. The device comprises a combustor, a fuel supply system, an air supply system, an exhaust pressure monitoring and controlling system and an igniting system which are respectively connected with an electronic control system, wherein the electronic control system comprises a control chip; an exhaust check valve is respectively arranged on the exhaust pipeline and controlled by the electronic control system. The regenerating method of the regenerating unit of the diesel particle trap comprises the following steps of: stopping exhaust; primarily igniting; secondarily heating; and regenerating the diesel particle trap. The fuel steam and pressurized air are premixed and fully combusted, andthe diesel particle trap is uniformly heated through a rotary fire field to rapidly reach the particle combusting temperature to ensure that particles in the diesel particle trap are combusted, so that the purpose of regenerating the diesel particle trap is achieved.

Description

technical field [0001] The invention belongs to the technical field of diesel engine exhaust particle pollution control, and further relates to a regeneration device and regeneration method of a diesel engine particle filter under all working conditions. Background technique [0002] Diesel particulate filter (DPF) is an effective way to reduce the emission of diesel exhaust particulate matter, and the regeneration of particulate filter (treatment after particulate capture) is the main difficulty in application. [0003] Thermal regeneration is a more commonly used regeneration method. By heating to increase the exhaust gas temperature or directly selectively heating the particles, the particles deposited in the trap are burned to restore the performance of the trap. The method of using the burner to heat the exhaust gas has better feasibility than other methods. [0004] At present, the burner heating regeneration device mainly has the following problems: [0005] (1) The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F01N3/025F02D43/00

Inventor 资新运姜大海刘宏威姚广涛张春润徐正飞卜建国庞海龙邓成林柳贵东

Owner MILITARY TRANSPORTATION UNIV PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com