Process gas afterheat recovery device of coking carbonization chamber furnace top and heat-removing element

A waste heat recovery device and process gas technology, applied in coke oven heating, coke oven, dry distillation gas discharge device, etc., can solve the problems that waste heat recovery cannot be conveniently and effectively applied, and improve comprehensive energy utilization efficiency and heat extraction efficiency High, improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

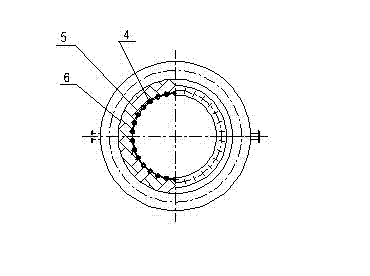

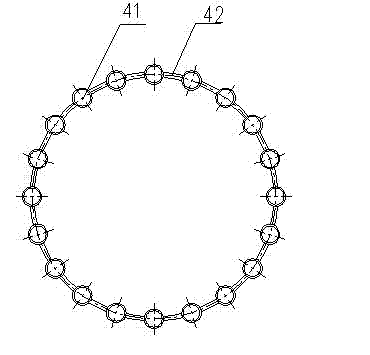

[0033] Such as figure 1 As shown, when the outer tube diameter d of the heat pipe 41 is less than or equal to 25mm, and the central arc length of two adjacent heat pipes is less than or equal to 2d, the circumferential ring fins are used, that is, the ring fins 42 are placed between the heat pipes 41. The annular line formed by the center of the tube is connected with each heat pipe 41 .

Embodiment 2

[0035] Such as figure 2 As shown, when the outer diameter d of the heat pipe 41>25mm, and the central arc length of two adjacent heat pipes is less than or equal to 2d, the circumferential cut tube fins are used, that is: the annular fins 42 and each The heat pipes 41 are tangential to each other in the circumferential direction, and the inner peripheral surface of the annular fin 42 coincides with the inner peripheral surface formed by each heat pipe 41 .

Embodiment 3

[0037] Such as image 3 As shown, the annular circumferential tube-fin screen adopts a circumferential tube-fin screen with an inner cylinder, that is, the annular fin screen 42 is connected with each heat pipe 41 on its outer circumferential surface. The annular fin screen 42 becomes the inner cylinder of the circumferential tube fin screen.

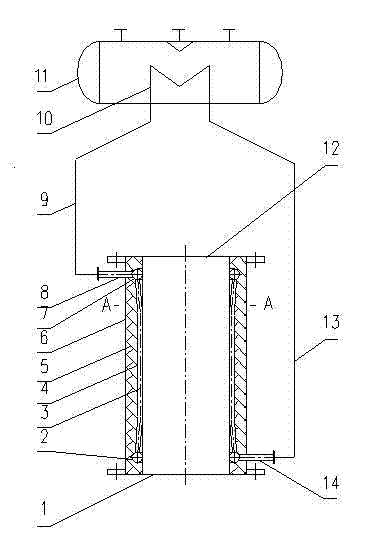

[0038] Such as Figure 4 , Figure 5 As shown, the waste heat recovery device for process gas at the top of the coking chamber of the present invention includes an annular circumferential tube-fin screen 4, an upper collection coil 7, a lower collection coil 2, a heat release pipe 10, and a steam drum 11. A process gas outlet 12 and a process gas inlet 1 are respectively provided at the upper and lower ports of the tube-fin screen 4, and the process gas inlet 1 is connected to the top of the coking chamber furnace; wherein, the lower ends of the heat pipes of the annular circumferential tube-fin screen 4 pass through The lower collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com