Method for preparing 3-methoxy-4-hydroxy mandelic acid

A technology of hydroxymandelic acid and methoxyl group, applied in the field of preparing 3-methoxy-4-hydroxymandelic acid by glyoxylic acid method, can solve problems such as unsatisfactory yield, and achieve improved utilization rate and condensation product yield improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

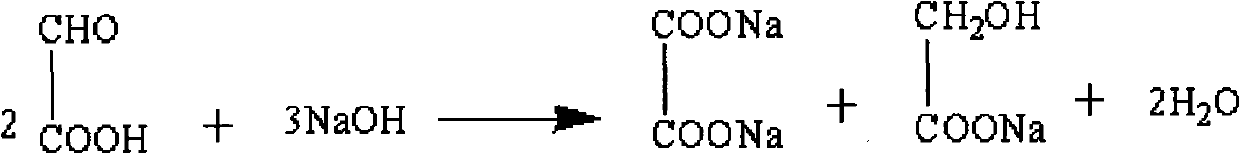

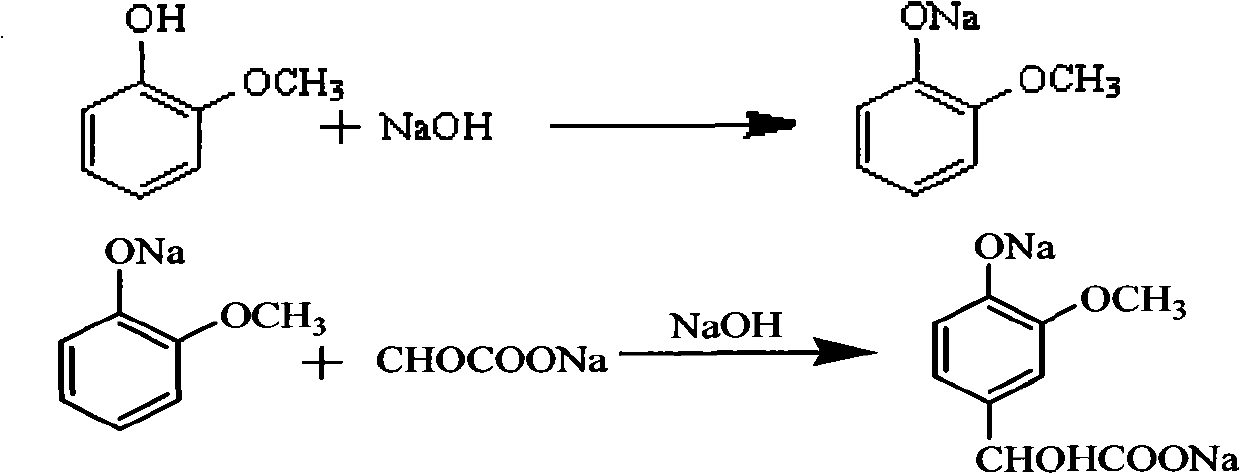

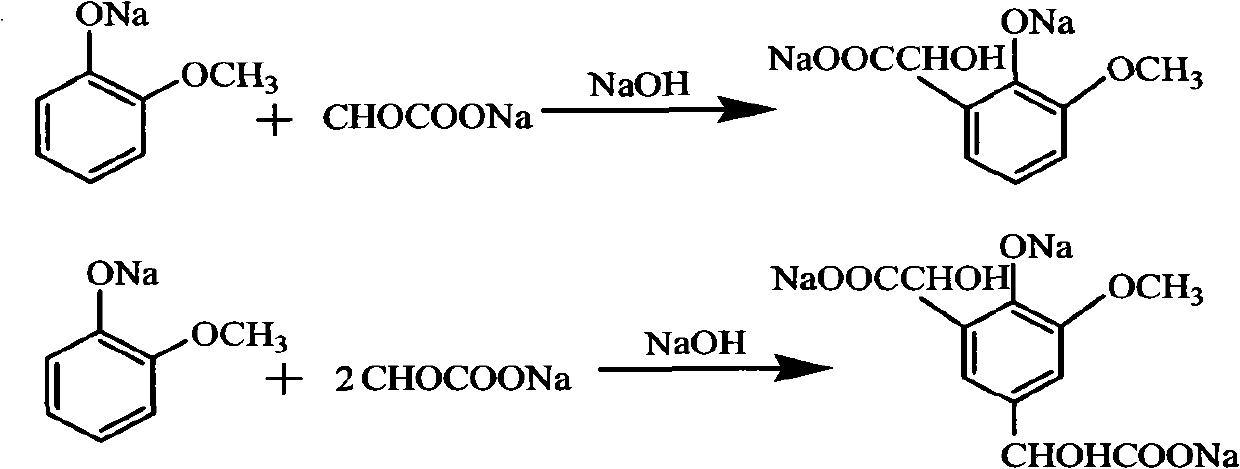

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 22.3g of glyoxylic acid with a content of 33.3wt%, add it into 48.5g of water under stirring to make 10.56wt% glyoxylic acid, and slowly add 30wt% sodium hydroxide solution dropwise at a temperature of 10°C , adjust the pH value of the solution to 4.5, and prepare the sodium glyoxylate solution for use.

[0028] (2) Weigh 16.0g of guaiacol with a content of 99wt%, add 180g of water under nitrogen protection and stirring, the reaction temperature is 10°C, slowly add 30wt% sodium hydroxide solution dropwise, and adjust the pH value of the solution to 11 , to prepare sodium guaiacol solution.

[0029] (3) Control the reaction temperature by a water bath at 10-13°C, slowly add the sodium glyoxylate solution prepared in the above (1) dropwise to the sodium guaiacol solution prepared in the above (2) under nitrogen protection and stirring In, add dropwise for 52min. Stirring was continued for 1 h, and the reaction temperature was static for 27 h. Then use 50wt% s...

Embodiment 2

[0031] (1) Take by weighing 22.3g content and be the glyoxylic acid of 33.3wt%, add under stirring in 48g water, be made into the glyoxylic acid of 10.56wt%, under 20 ℃ of reaction temperature, slowly add dropwise the sodium hydroxide solution of 30wt%, Adjust the pH value of the solution to 4.5 and set it aside.

[0032] (2) Take 20.1g of guaiacol with a content of 99wt%, add 180g of water under nitrogen protection and stirring, at a reaction temperature of 12°C, slowly add 30% sodium hydroxide solution dropwise, and adjust the pH value of the solution to 11, stand-by.

[0033] (3) Control the reaction temperature by a water bath at 10-13°C, under nitrogen protection and stirring, slowly add the sodium glyoxylate solution prepared in the above (1) dropwise to the sodium guaiacol prepared in the above (2) In the solution, after adding dropwise for 60 minutes, continue to stir for 1 hour, then react statically at the above reaction temperature for 27 hours, and then use 50 wt%...

Embodiment 3

[0035] (1) Take by weighing 22.3g content and be the glyoxylic acid of 33.3wt%, add under stirring in 48g water, be made into the glyoxylic acid of 10.56wt%, under the reaction temperature 25 ℃, slowly drop the sodium hydroxide solution of 30wt%, Adjust the pH value of the solution to 4.5 and set it aside.

[0036] (2) Take 20.1g of guaiacol with a content of 99wt%, add 180g of water under nitrogen protection and stirring, at a reaction temperature of 15°C, slowly add 30wt% sodium hydroxide solution dropwise, and adjust the pH value of the solution to 11, stand-by.

[0037] (3) Control the reaction temperature by a water bath at 12-15°C, under nitrogen protection and stirring, slowly add the sodium glyoxylate solution prepared in the above (1) dropwise to the sodium guaiacol prepared in the above (2) Add dropwise to the solution for 65 minutes, continue to stir for 1 hour, and react statically at the above temperature for 26 hours, then acidify the reaction solution with 50 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com