Low-temperature demulsifier for crude oil emulsion and production method thereof

A production method and technology of demulsifiers, applied in the field of low-temperature demulsifiers, can solve problems such as poor applicability, poor solubility, poor dispersion performance, and excess, and achieve the effects of enhanced application performance and effect, clear oil-water interface, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0022] Crude oil emulsion low temperature demulsifier composition: polyether type demulsifier (brand: BP2040), 10%; phenolic resin type polyether demulsifier (brand: AR36), 20%; phenolic resin type polyether demulsifier (brand: BASOROL P DB-9945), 20%; dodecylbenzenesulfonic acid, 0.5%; mixed aromatic solvent (brand: S-1000), 48.5%; isopropanol, 1%.

[0023] Heat the demulsifier dry agent to 80°C in a water bath to make it have better fluidity. Add 485 kg of mixed aromatic solvent S-1000 and 10 kg of isopropanol into a reaction kettle with a heat preservation jacket, and add 100 kg of heated functional demulsifier BP2040 in batches at a stirring speed of 120 r / min. Kilogram, 200 kilograms of AR36, 200 kilograms of BASOROL P DB-9945, finally add 5 kilograms of additive dodecylbenzenesulfonic acid, and continue to stir to obtain the final product after 15 minutes.

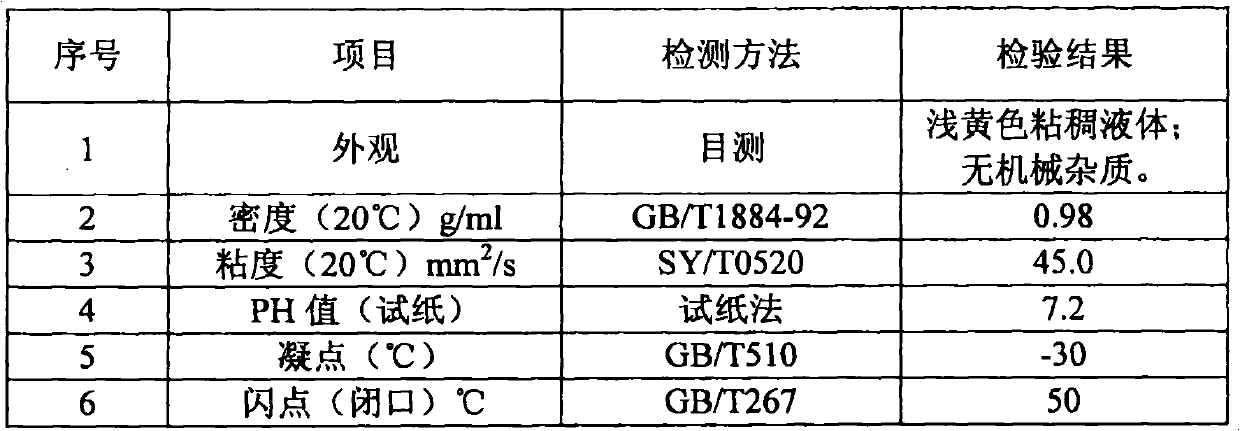

[0024] The performance index of obtained crude oil emulsion low temperature demulsifier is as follows:

[0025] ...

Embodiment B

[0027] Crude oil emulsion low temperature demulsifier composition: polyether type demulsifier (brand: AP121), 15%; Phenolic resin type polyether demulsifier (brand: BASOROL P DB-9947), 20%; Polyamine polyether demulsifier ( Brand: BASOROL 701), 20%; dodecylbenzenesulfonic acid, 0.55%; mixed aromatic solvent (brand: S-1500), 42.45%; isopropanol, 2%.

[0028] Heat the demulsifier dry agent to 80°C in a water bath to make it have better fluidity. Add 424.5 kg of mixed aromatic solvent S-1500 and 20 kg of isopropanol into a reaction kettle with a heat preservation jacket, and add 150 kg of heated functional demulsifier AP121 in batches at a stirring speed of 120 r / min. Kilogram, 200 kilograms of BASOROL P DB-9947, 200 kilograms of BASOROL701, finally add 5.5 kilograms of additive dodecylbenzenesulfonic acid, and continue to stir to obtain the final product after 15 minutes.

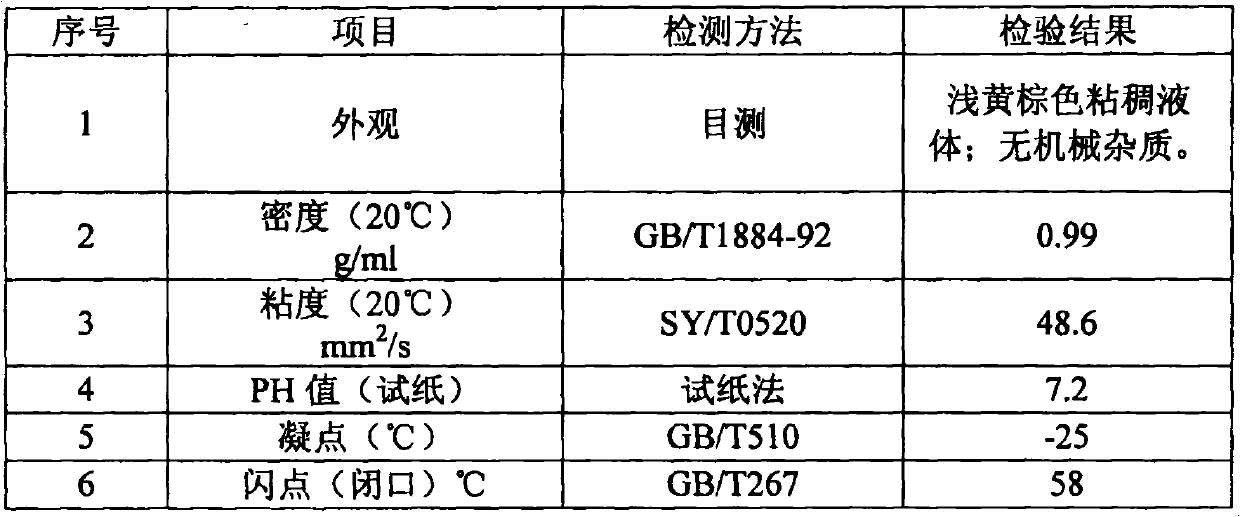

[0029] The performance index of obtained crude oil emulsion low temperature demulsifier is as follows:

...

Embodiment C

[0032] Crude oil emulsion low temperature demulsifier composition: phenolic resin type polyether demulsifier (brand: BASOROL P DB-9935), 15%; PO / EO block polyether demulsifier (brand: BASOROL 150R1), 15%; multifunctional type Polyether demulsifier (brand: BASOROLE9289), 20%; dodecylbenzenesulfonic acid, 0.5%; mixed aromatic solvent (brand: S-1500), 48%; isopropanol, 1.5%.

[0033] Heat the demulsifier dry agent to 80°C in a water bath to make it have better fluidity. Add 480 kg of mixed aromatic solvent S-1500 and 15 kg of isopropanol into a reaction kettle with a heat preservation jacket, and add the heated functional demulsifier BASOROL P DB in batches at a stirring speed of 120 r / min -9935 counts 150 kg, BASOROL 150R1 counts 150 kg, BASOROLP E9289 counts 200 kg, finally adds 5 kg of additive dodecylbenzenesulfonic acid, and continues stirring for 15 minutes to obtain the final product.

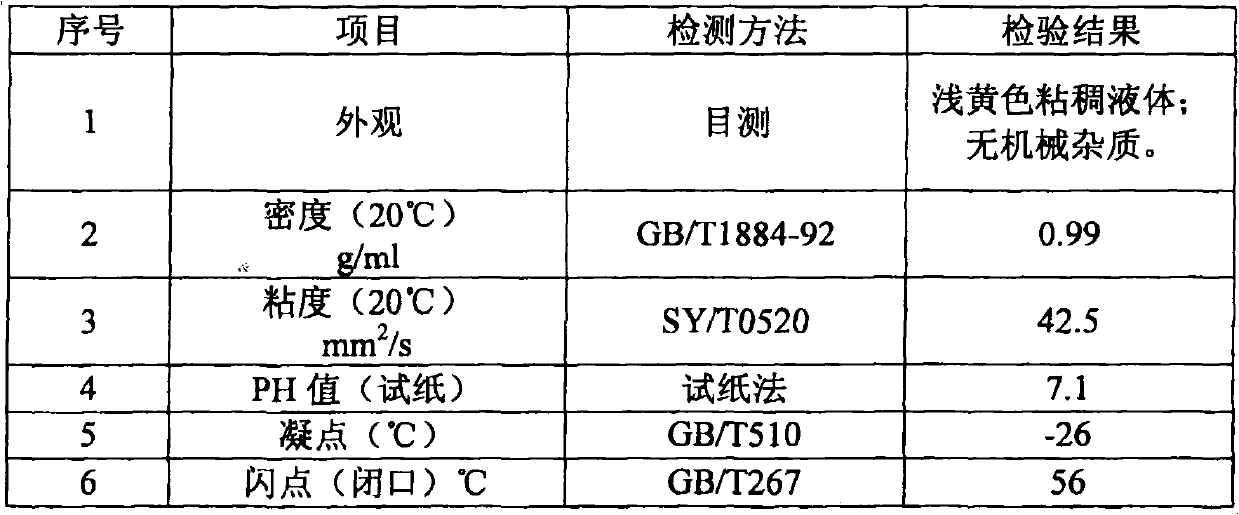

[0034] The performance index of obtained crude oil emulsion low temperature demulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com