Safflower oil tea seed low-temperature cold pressing technique

A safflower camellia, low-temperature technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem of loss of active ingredients and achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

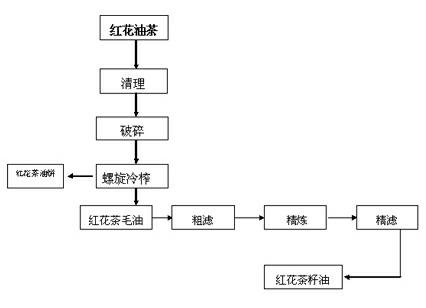

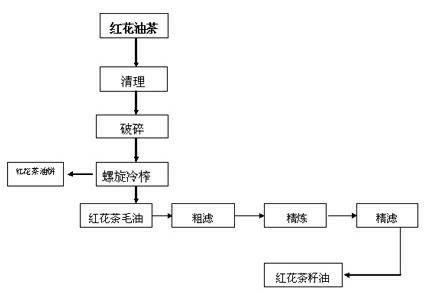

Image

Examples

Embodiment 1

[0019] A low-temperature cold pressing process for safflower camellia seed, the steps of which are:

[0020] a. removing impurities and cleaning the safflower camellia seed, drying after cleaning, and drying the safflower camellia seed until the water content is less than 8%;

[0021] b. The dried safflower camellia seeds are sent to the crusher for crushing until the safflower camellia seeds are broken into 6 to 8 petals with a particle size of 2-4mm. The speed of the crushing blade of the crusher is 1500-1900 rpm. The diameter of the belt pulley of the crusher motor is 110-130mm, and the diameter of the screen mesh is 9-11mm;

[0022] c. Start the screw oil press and run in rapeseed cake. The motor of the screw oil press is a 10KW four-stage motor, and the speed of the screw oil press is controlled at 30-40 rpm. 80-120mm;

[0023] d. After the rapeseed cake to be squeezed out is formed, send the crushed safflower camellia seeds into the screw oil press for cold pressing to...

Embodiment 2

[0026] After drying, the safflower camellia seeds with a moisture content of less than 8% are cleaned to remove the large impurities, small impurities and dust in the safflower camellia seeds. Measure 1000 kg, pour it into the crusher, and break it into 6 to 8 petals of granules. After running the oil press with rapeseed cake, pour the broken safflower camellia seed granules into the oil press and start pressing safflower camellia Seed oil, through 8 hours of continuous oil extraction, get 210 kilograms of safflower camellia seed crude oil, 720 kilograms of safflower camellia seed oil cake. Measure 2000 kg, pour it into the crusher, break it into 6 to 8 petals of particles, add it to the oil press continuously, and continue to produce for 16 hours to get 430 kg of safflower camellia seed crude oil and 1420 kg of safflower camellia seed oil. Camellia oleifera seed oil cake, weighing 3000 kg, poured into the crusher, crushed into 6 to 8 petals of particles, continuously added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com