Method for adjusting real-time monitor device in exposure path of concave holographic grating

A holographic grating and real-time monitoring technology, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, diffraction gratings, etc. The effect of misalignment of light, improving the production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

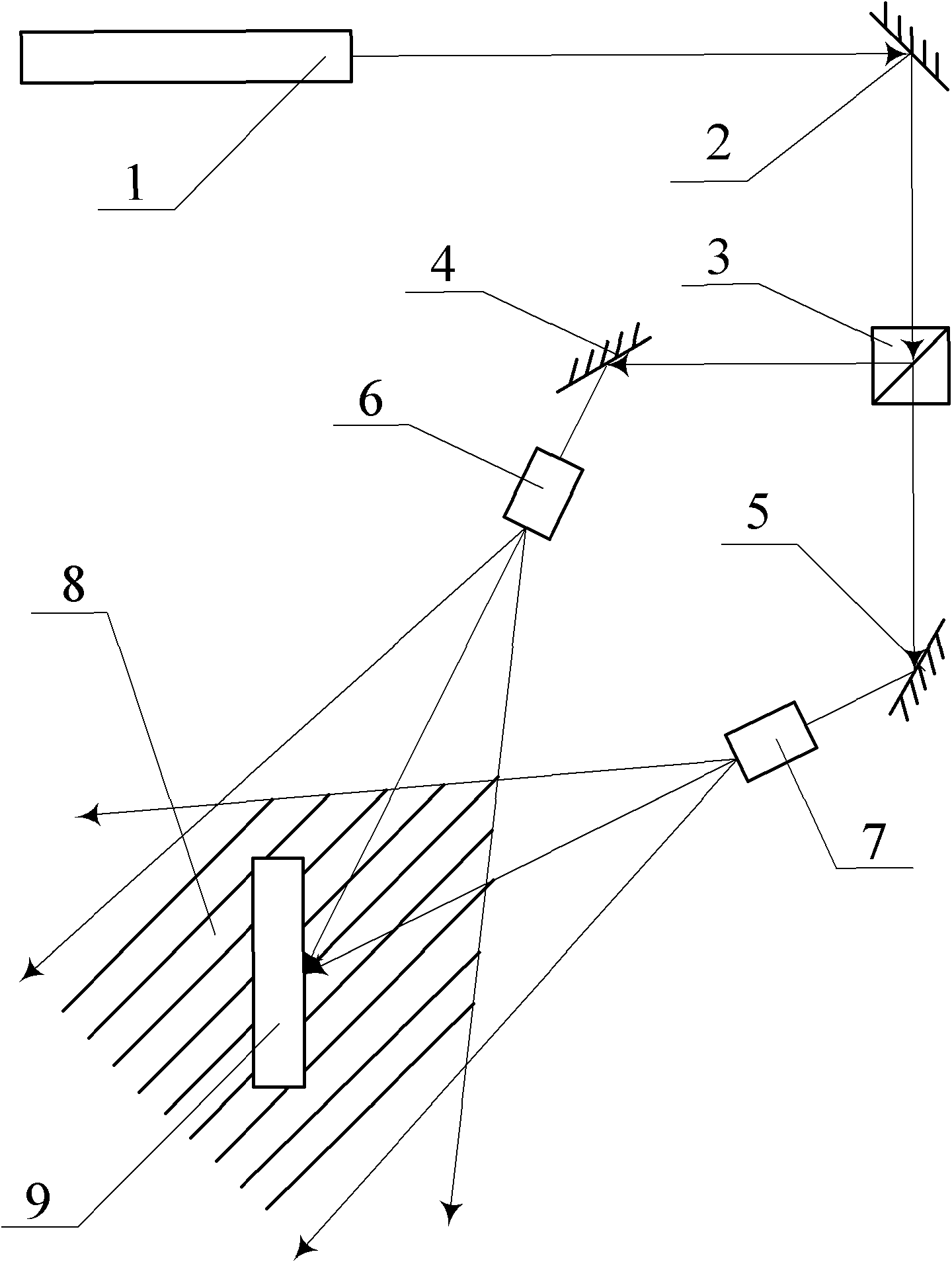

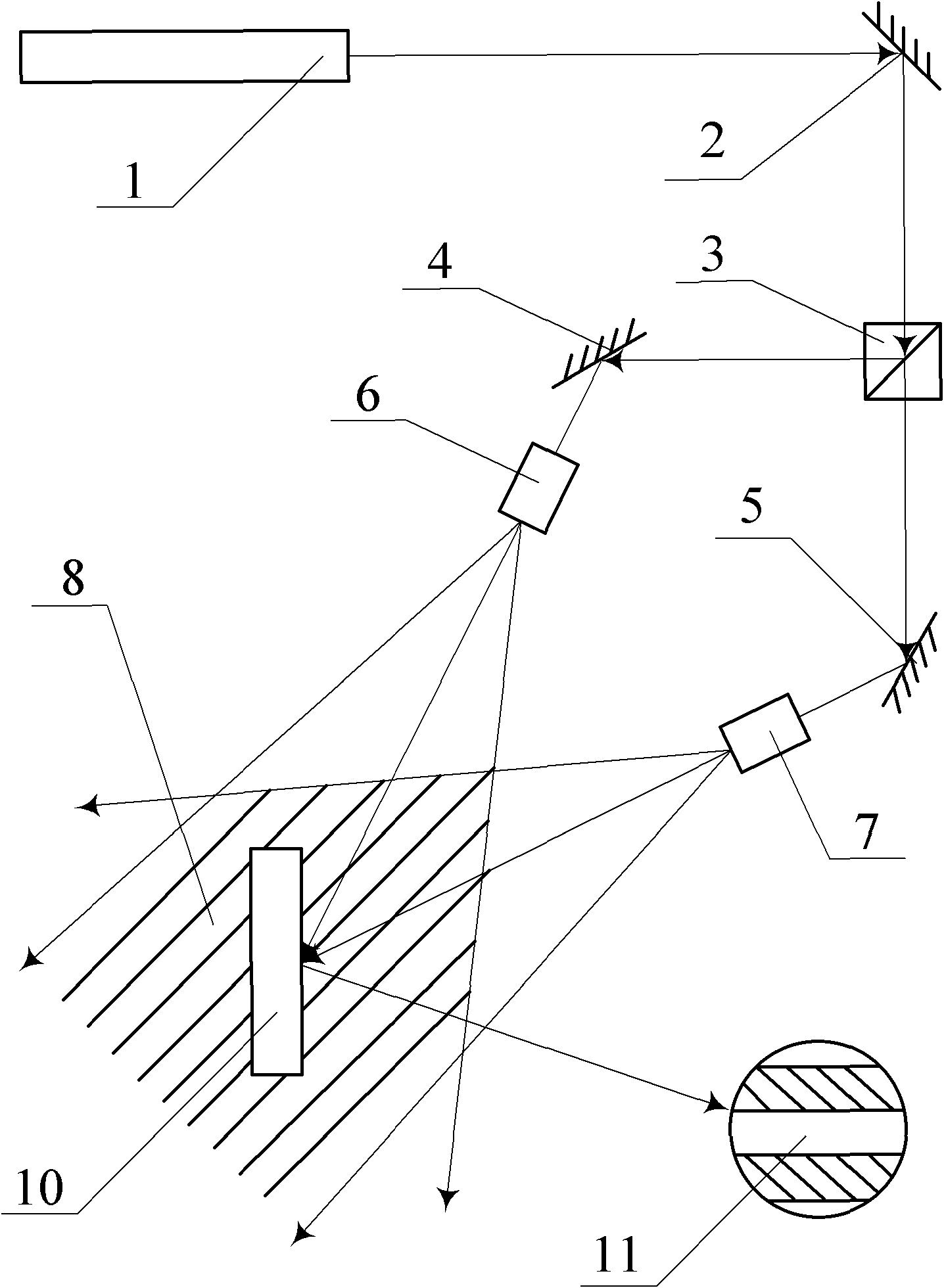

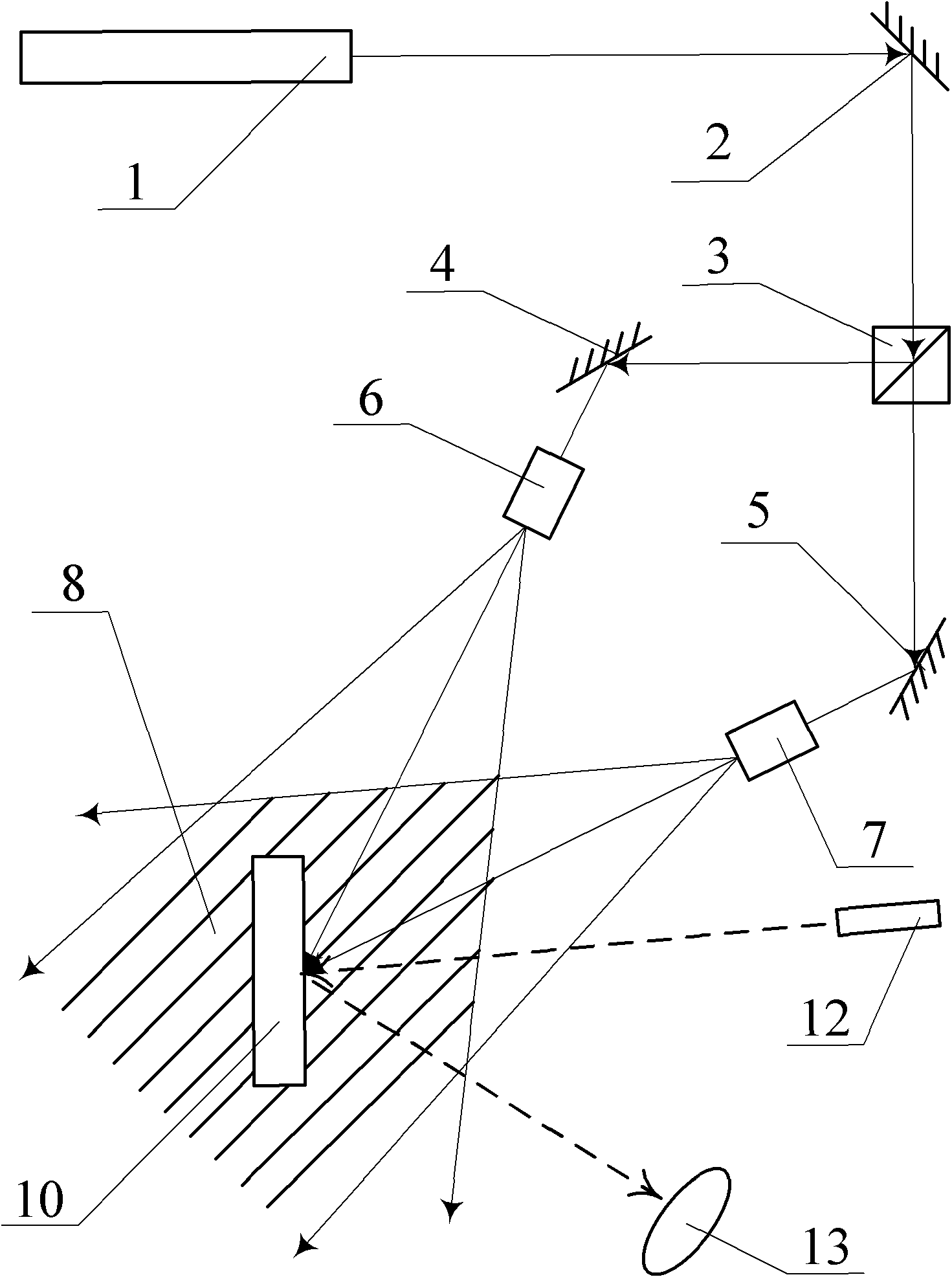

[0011] The present invention is implemented according to three method steps of step 1, step 2 and step 3 established in the technical solution to be solved. Among them, the light source laser 1 adopts Kr + Laser, the emission wavelength is 413.1nm; the first plane mirror 2, the second plane mirror 4 and the third plane mirror 5 are aluminum-plated mirrors on glass substrates; the beam splitter 3 adopts double-glued glass prisms; 6 and the second spatial filter 7 are composed of a microscope objective lens and a pinhole; the grating substrate 9 and the holographic grating 10 are made of K9 optical glass, and the photoresist coated on the K9 optical glass is Japanese Shipley 1805 positive photoresist etchant; the receiving screen 11 is made of white frosted glass; the monitoring laser 12 is a He-Ne laser with an emission wavelength of 632.8nm; the photodetector 13 is a photomultiplier tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com