Method for oriented growth of one-dimensional inorganic nanowire array on metal substrate

A technology of metal substrates and nanowires, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of many surface defects, not very smooth, and expensive semiconductors on the surface of nanowires, and achieve simple preparation methods, The effect of cheap equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

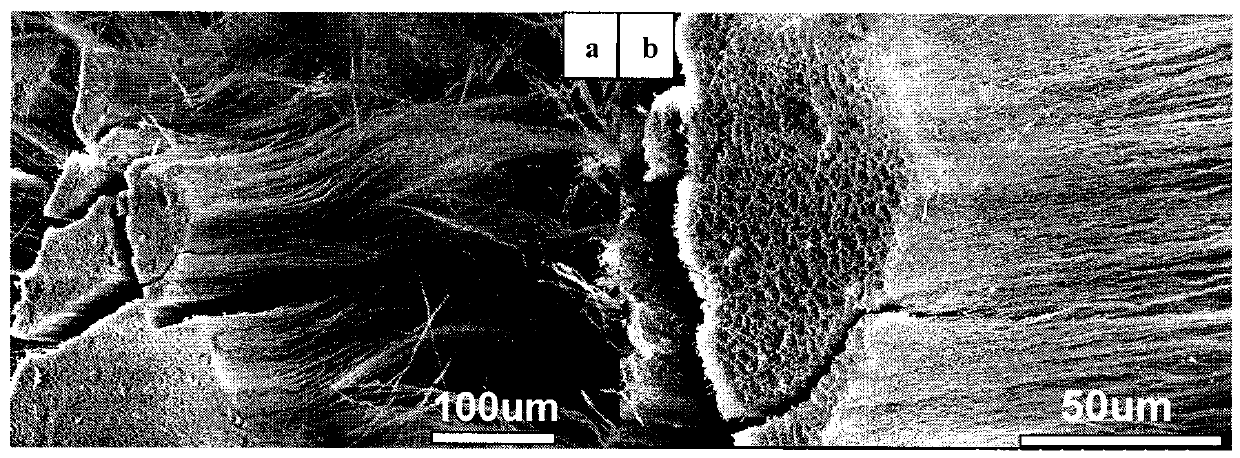

[0029] Embodiment 1, prepare SiO on Sn substrate 2 nanowire array

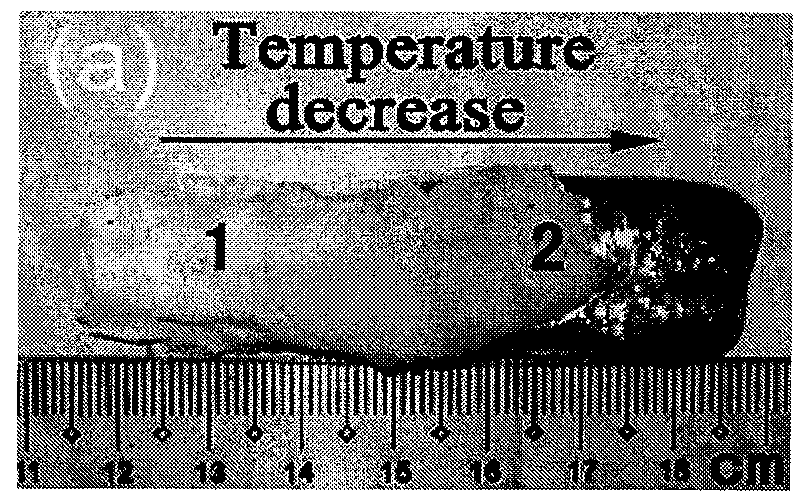

[0030] Take 0.2g-0.8g SiO powder, put it in a porcelain boat, put the porcelain boat in the high temperature zone of the vacuum tube furnace, take 90 grams of tin powder (the mass should be 100 times the mass of SiO, because the size of the furnace cavity is limited, so The appropriate mass of Sn that can be accommodated on both sides is about 50g) respectively placed in a porcelain boat container, placed on both sides of the high-temperature center 10-16cm, and the vacuum tube furnace is closed; the pressure in the furnace cavity is lower than 1x10 3 After Pa, argon gas is introduced until the pressure is (4-6)x10 4 Pa, and then evacuate until the pressure in the furnace chamber is lower than 1x10 3 Pa, after repeating this 3 times to ensure that the lumen is in an oxygen-free state, use argon to fill the lumen pressure to 1x10 3 Pa, sealed vacuum tube; start heating the high temperature zone of the furna...

Embodiment 2

[0032] Embodiment 2, prepare Si nanowire on Sn substrate

[0033] According to the method of Example 1, a hierarchical structure array of Si nanowires perpendicular to the metal tin substrate was prepared. The difference is that the amount of precursor SiO used in this example is 1.6-2g, the mass of tin powder is 80g (50 times lower than the mass of SiO), and the position is placed on both sides of the high temperature center 14-20cm area, the non-oxidizing protective gas used is argon-hydrogen mixed gas (volume ratio 95:5), and the duration of the SiO precursor in this embodiment at 1360°C is 50 minutes to 120 minutes.

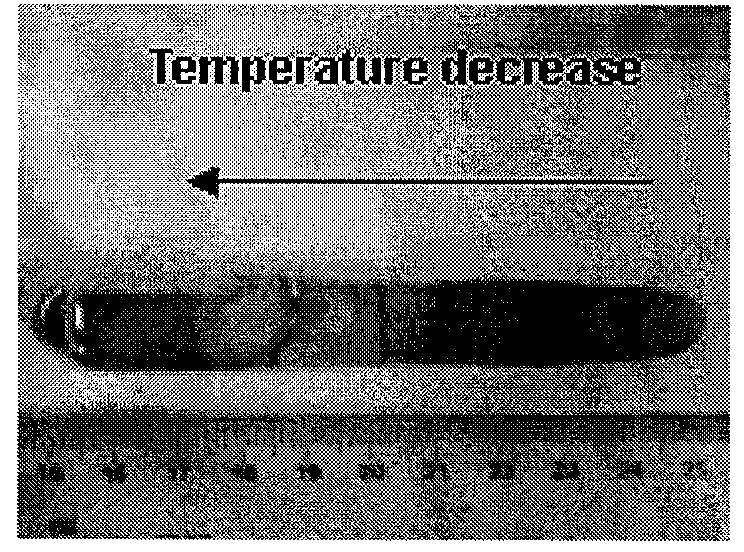

[0034] The product is directly taken out from the furnace cavity, and from its optical photograph (see image 3 ) It can be seen that along the direction of temperature drop, a product with a larger area is obtained from the left side of the high temperature to the right side of the low temperature, and the obtained product area is limited by the size of the v...

Embodiment 3

[0035] Embodiment 3, prepare SiO on Sn substrate 2 Nanowire and Si nanowire composite structure array

[0036] Prepare SiO perpendicular to the metal tin substrate according to the method of Example 1 2 Hierarchical composite structure arrays of nanowires and Si nanowires. The difference is: the amount of precursor SiO used in this embodiment is 0.9-1.5g, the mass of tin powder is 100g (50 times higher than SiO mass and lower than 100 times SiO mass), and it is placed at a distance In the area on both sides of the 10-20cm high temperature center, the non-oxidizing protective gas used is nitrogen, and the duration of the precursor SiO at 1360 degrees is 180 minutes to 300 minutes.

[0037] The product is directly taken out from the furnace cavity, and from its optical photos (such as Figure 5 ) It can be observed that along the direction of temperature drop, the length of the product obtained from the right side of the high temperature to the left side of the low temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com