Method for preparing high-purity zinc hydroxide and zinc white from filter residues discharged during producing sodium hydrosulfite

A technology of zinc hydroxide and hydrosulfite, applied in the direction of zinc oxide/zinc hydroxide, solid waste removal, etc., can solve the problems of not dealing with hydrosulfite and slag, not producing high-purity zinc hydroxide and zinc white, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

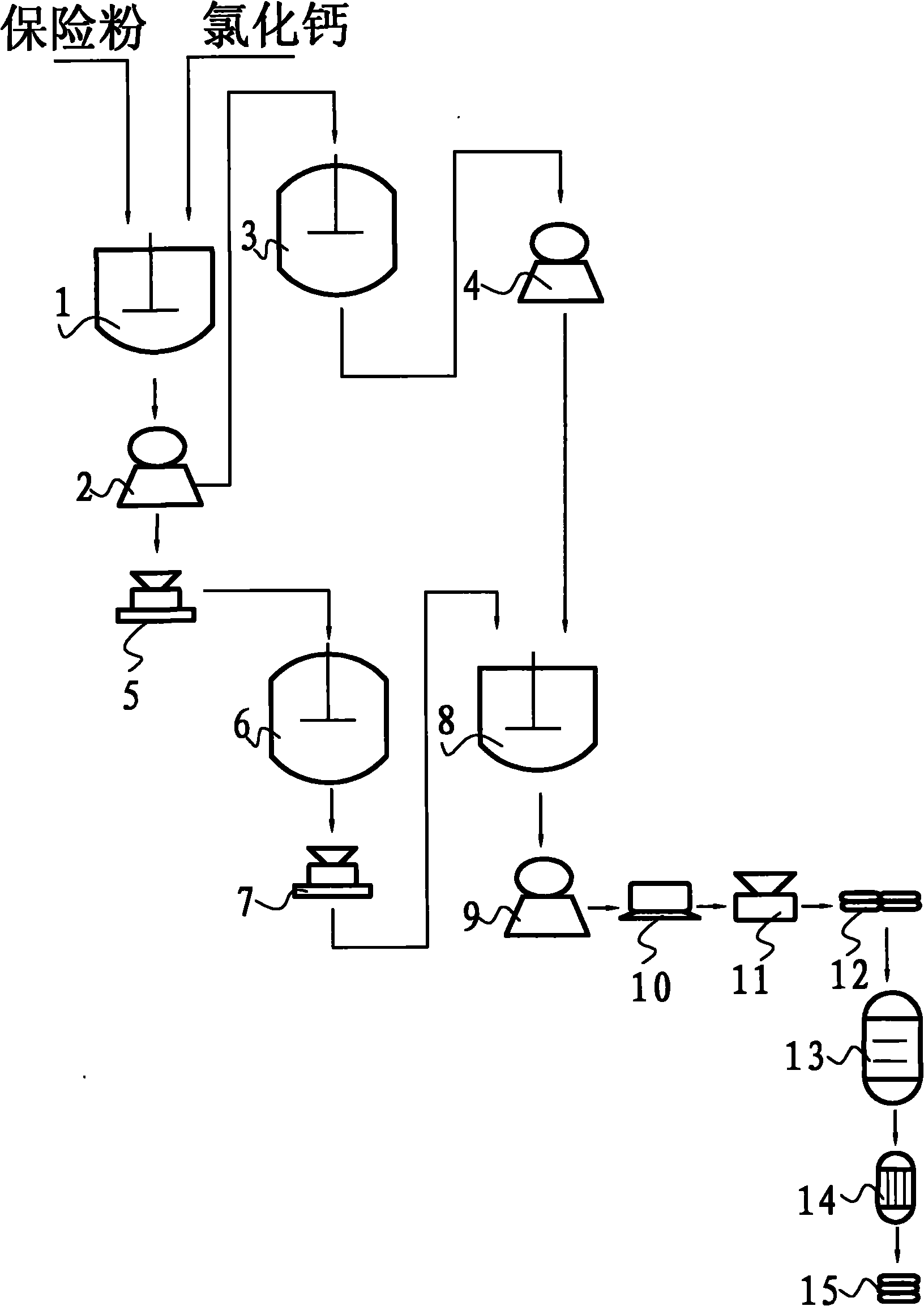

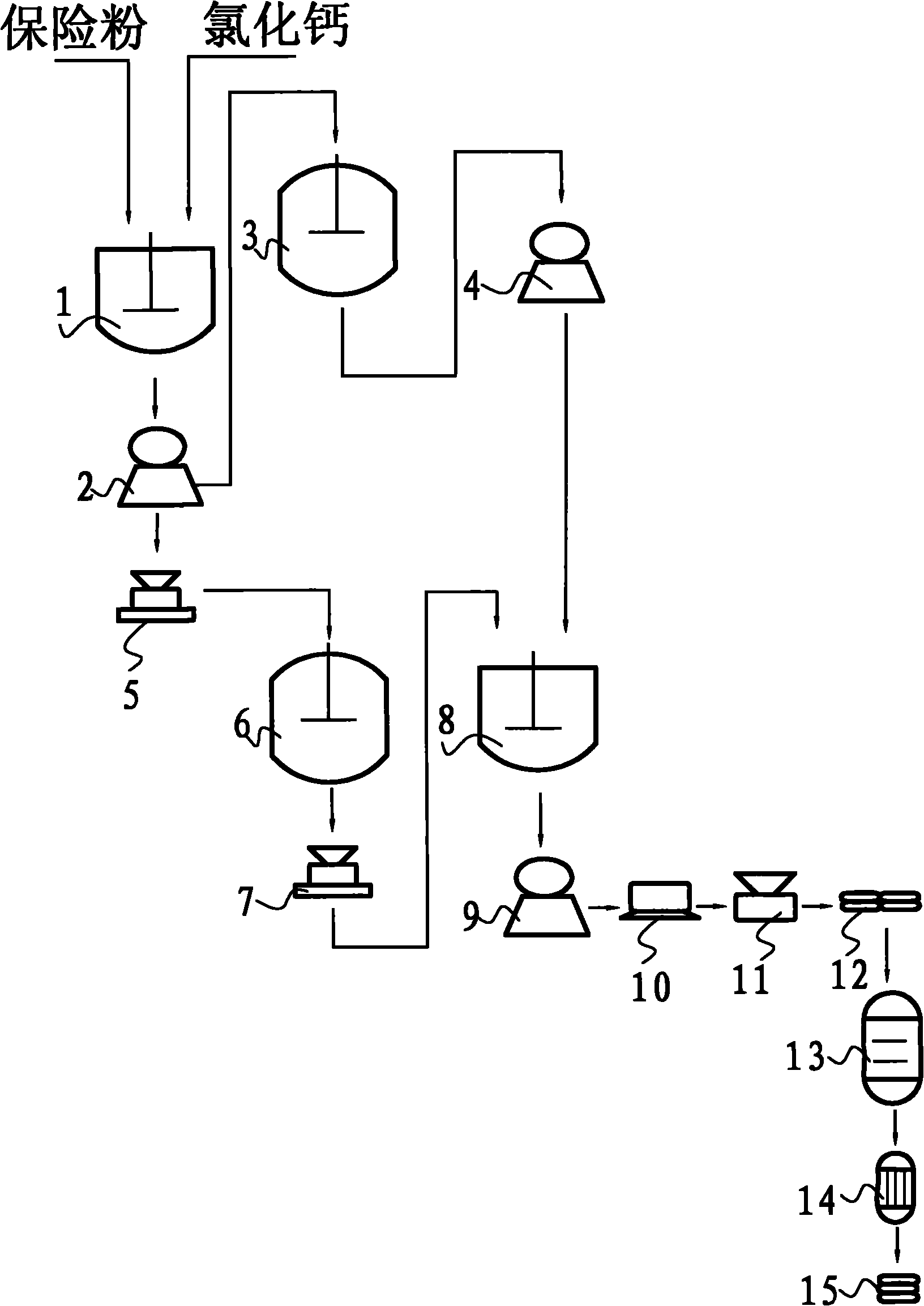

[0027] A method for manufacturing high-purity zinc hydroxide and zinc white with hydrosulfate slag, the preparation steps are as follows:

[0028] Step A, drop into the first anti-corrosion reactor 1 successively with pure mass ratio 1: 0.92 to carry out agitation reaction with the hydrosulfite filter that has been converted and the ammonia-alkali waste liquid that contains calcium chloride, (wherein calculate by pure 500kg hydrogen oxidation Calculation of zinc, wherein the water content is 40%, and the side pure zinc hydroxide is 300kg) reacts to obtain calcium hydroxide solid and zinc chloride liquid, and the described hydrosulfite is converted according to pure zinc hydroxide, and the ammonia-alkali waste liquid case is pure Calcium chloride is converted;

[0029] Step B, the reaction mixture obtained in the step A is filtered with the first filter 2, the filtrate is transferred in the first reactor 3, then in the first reactor 3, drop into zinc hydroxide to remove impurit...

Embodiment 2

[0036] A method for manufacturing high-purity zinc hydroxide and zinc white with hydrosulfate slag, the preparation steps are as follows:

[0037] A method for manufacturing high-purity zinc hydroxide and zinc white with sodium hydrosulfate slag, the preparation steps are as follows:

[0038] Step A, put the converted hydrosulfite filter and the ammonia-alkali waste liquid containing calcium chloride into the first corrosion-resistant reactor 1 successively with a pure mass ratio of 1: 1.12 to carry out stirring reaction, (wherein calculate by pure 500kg hydrogen oxidation Calculation of zinc, wherein the moisture content is 40%, and the side pure zinc hydroxide is 300kg), the reaction obtains calcium hydroxide solid and zinc chloride liquid, and the described sodium hydrochloride is converted according to pure zinc hydroxide, and the ammonia-alkali waste liquid case Pure calcium chloride is converted;

[0039] Step B, the reaction mixture obtained in the step A is filtered w...

Embodiment 3

[0046] A method for manufacturing high-purity zinc hydroxide and zinc white with hydrosulfate slag, the preparation steps are as follows:

[0047] Step A, drop into the first anti-corrosion reactor 1 successively with pure mass ratio 1: 1.32 to carry out agitation reaction with the ammonia-alkali waste liquid that converted good sodium hydrochloride filter and containing calcium chloride, (wherein calculate by pure 500kg hydrogen oxidation Calculation of zinc, wherein the moisture content is 40%, and the side pure zinc hydroxide is 300kg), the reaction obtains calcium hydroxide solid and zinc chloride liquid, and the described sodium hydrochloride is converted according to pure zinc hydroxide, and the ammonia-alkali waste liquid case Pure calcium chloride is converted;

[0048] Step B, the reaction mixture obtained in the step A is filtered with the first filter 2, the filtrate is transferred in the first reactor 3, then in the first reactor 3, drop into zinc hydroxide to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com