Method for preparing high-purity manganese carbonate and co-producing gypsum by processing waste sulfuric acid with manganese spar

A technology of manganese carbonate and rhodochrosite, applied in chemical instruments and methods, calcium/strontium/barium sulfate, manganese compounds, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

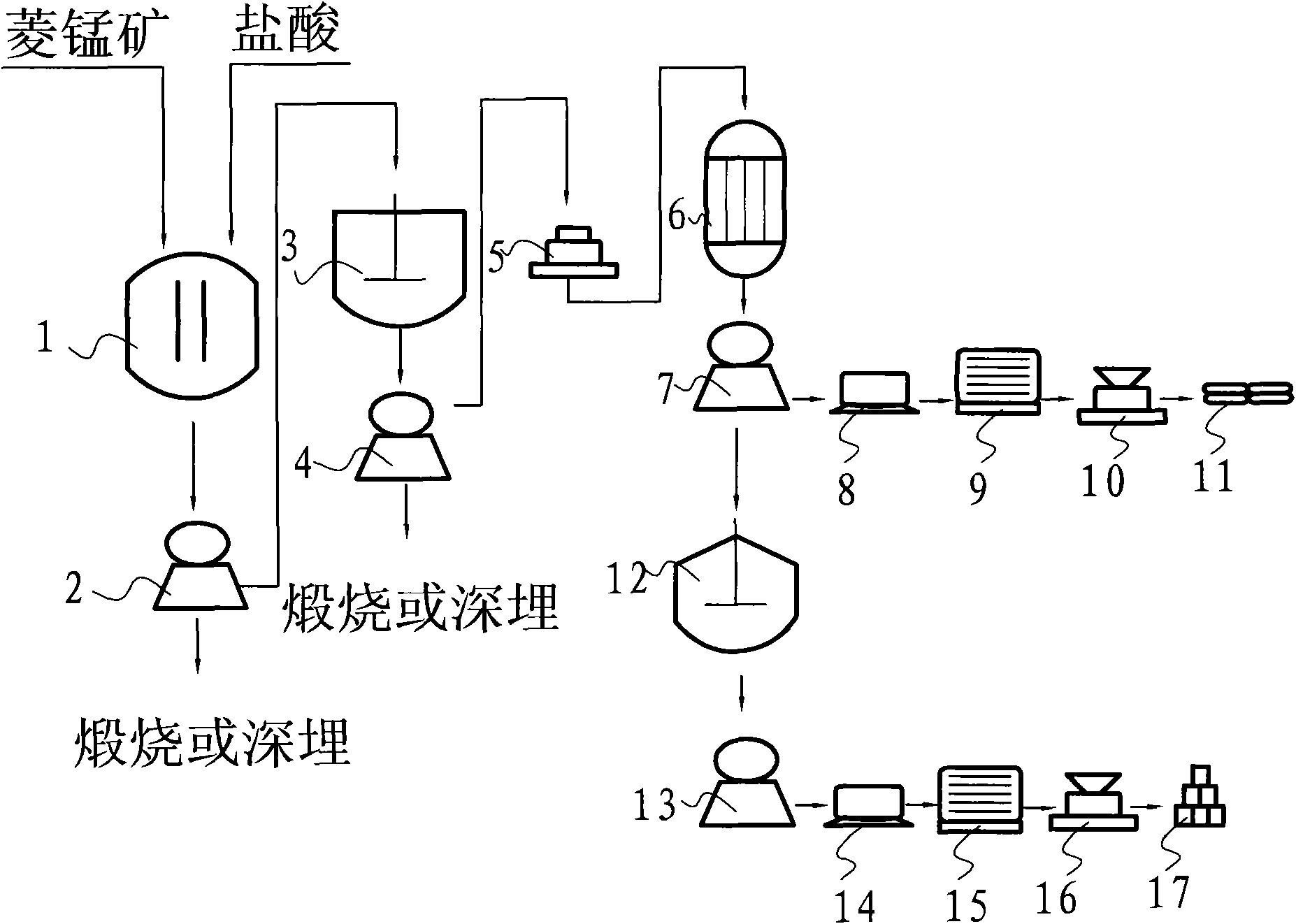

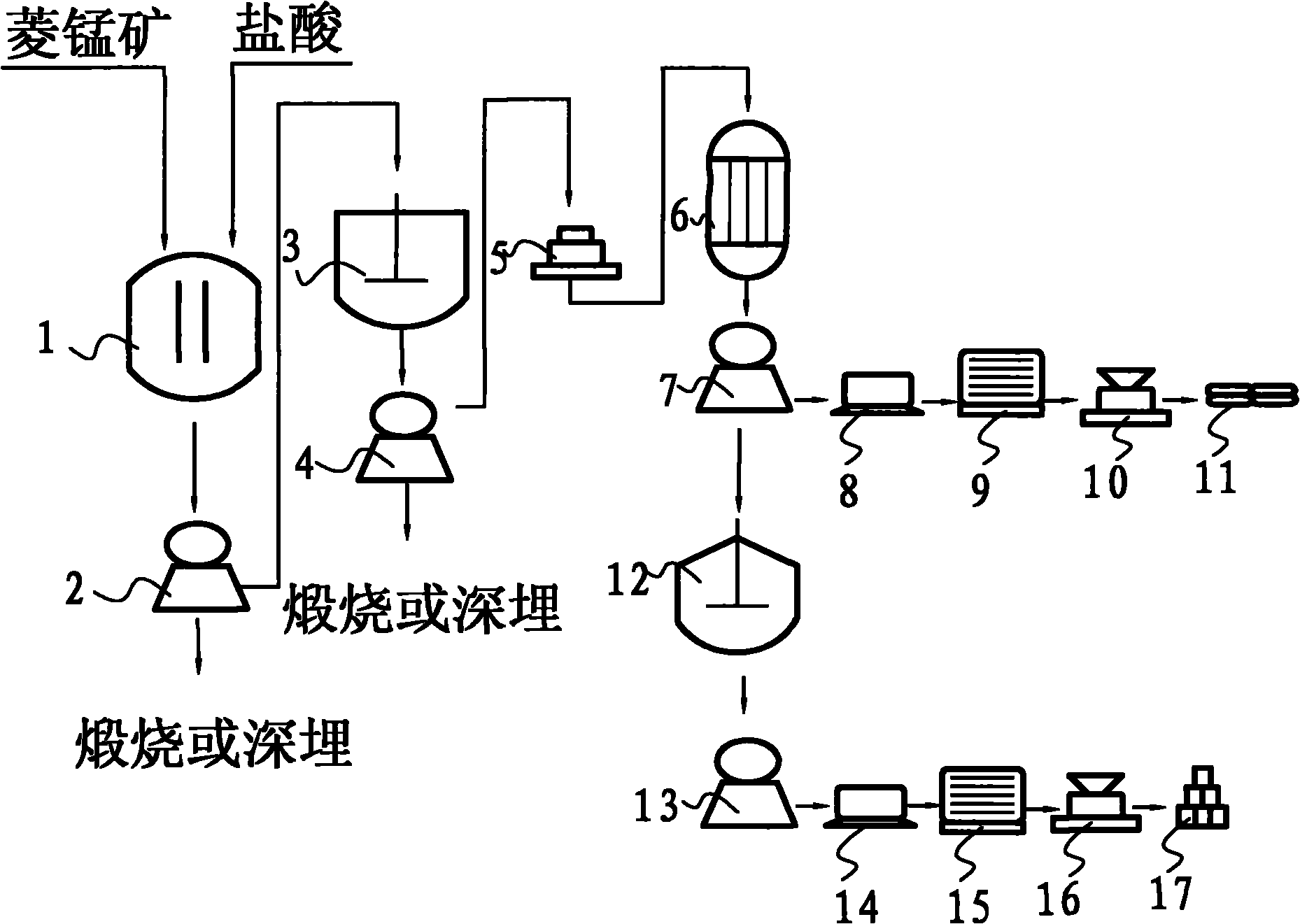

Method used

Image

Examples

Embodiment 1

[0034] The method for preparing high-purity manganese carbonate and producing gypsum by treating waste sulfuric acid with rhodochrosite, the preparation steps are as follows:

[0035] Step A, 800kg rhodochrosite is pulverized into 60 mesh coarse powder.

[0036] Step B, putting the rhodochrosite coarse powder into the leaching tank 1 equipped with hydrochloric acid, and leaching for 6 hours with a pure mass ratio of 1:0.43; The concentration is 15%.

[0037] Step C, the solid-liquid mixture leached in step B is filtered with the first filter 2, and the filter cake impurities are calcined or buried deeply.

[0038] Step D, the filtrate obtained by filtering in step C and sulfuric acid are successively dropped into the anticorrosion reactor 3 with a pure mass ratio of 1: 0.58 for stirring reaction; before the filtrate is reacted with sulfuric acid, the filtrate can also be treated with an appropriate amount of manganese hydroxide Pretreatment; the sulfuric acid used is the was...

Embodiment 2

[0047] The method for preparing high-purity manganese carbonate and producing gypsum by treating waste sulfuric acid with rhodochrosite, the preparation steps are as follows:

[0048] Step A, 800kg rhodochrosite is pulverized into 80 mesh coarse powder.

[0049] Step B, putting the rhodochrosite coarse powder into the leaching tank 1 equipped with hydrochloric acid, and leaching for 8 hours with a pure mass ratio of 1:0.63; The concentration is 17%.

[0050] Step C, the solid-liquid mixture leached in step B is filtered with the first filter 2, and the filter cake impurities are calcined or buried deeply.

[0051]Step D, the filtrate obtained by filtering in step C and sulfuric acid are successively dropped into the anticorrosion reactor 3 with a pure mass ratio of 1: 0.78 for stirring reaction; before the filtrate is reacted with sulfuric acid, the filtrate can also be treated with an appropriate amount of manganese hydroxide Pretreatment; the sulfuric acid used is the wast...

Embodiment 3

[0060] The method for preparing high-purity manganese carbonate and producing gypsum by treating waste sulfuric acid with rhodochrosite, the preparation steps are as follows:

[0061] Step A, 800kg rhodochrosite is pulverized into 120 mesh coarse powder.

[0062] Step B, put the rhodochrosite coarse powder into the leaching tank 1 equipped with hydrochloric acid, and leach for 10 hours with a pure mass ratio of 1:0.83; wherein, the rhodochrosite coarse powder (calculated as containing 13% manganese), the volume of The concentration is 20%.

[0063] Step C, the solid-liquid mixture leached in step B is filtered with the first filter 2, and the filter cake impurities are calcined or buried deeply.

[0064] Step D, the filtrate obtained by filtering in step C and sulfuric acid are successively dropped into the anticorrosion reactor 3 with a pure mass ratio of 1: 0.98 for stirring reaction; before the filtrate is reacted with sulfuric acid, the filtrate can also be treated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com