Barium titanate and barium ferrite composite powder with nucleus shell structure and preparation method thereof

A technology for structuring barium titanate and barium ferrite, which is applied in the fields of ferroelectric-ferromagnetic multifunctional composite powder materials and their preparation, core-shell structure barium titanate-barium ferrite composite powder materials and their preparation fields It can solve the problems of complicated operation, limited product purity, and difficult to control the supersaturation of the solution, and achieve the effect of simple preparation method and strong magnetoelectric coupling coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

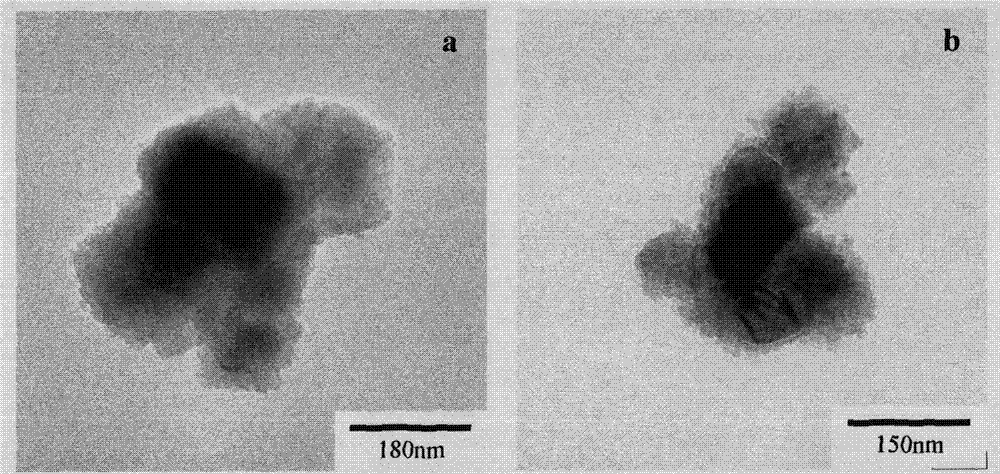

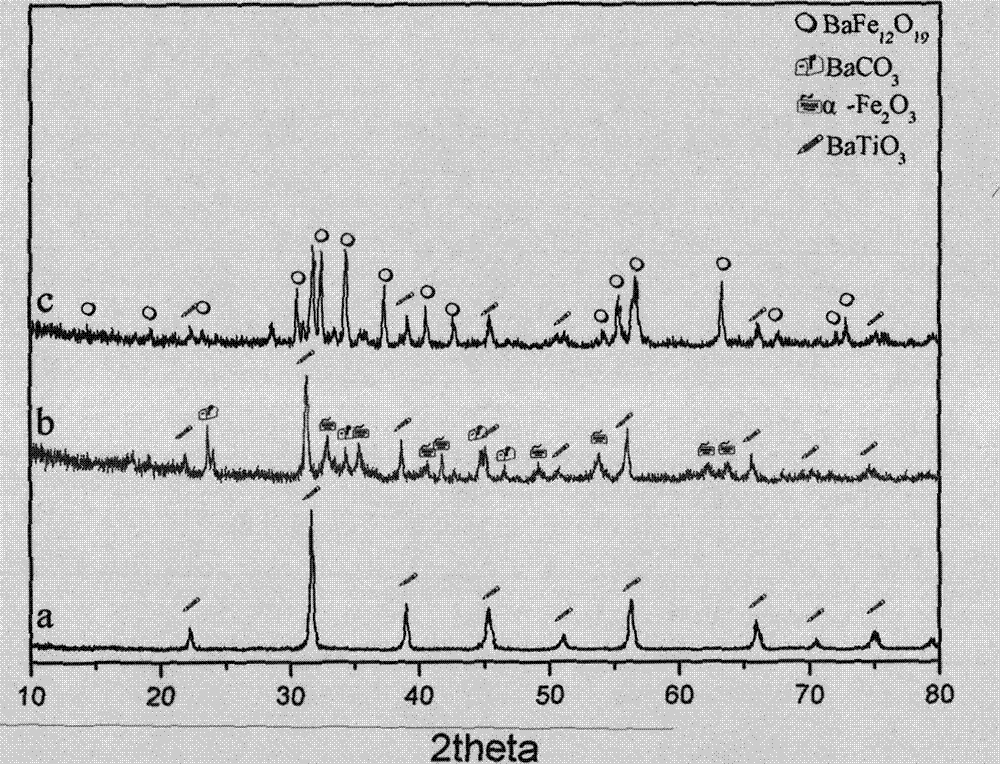

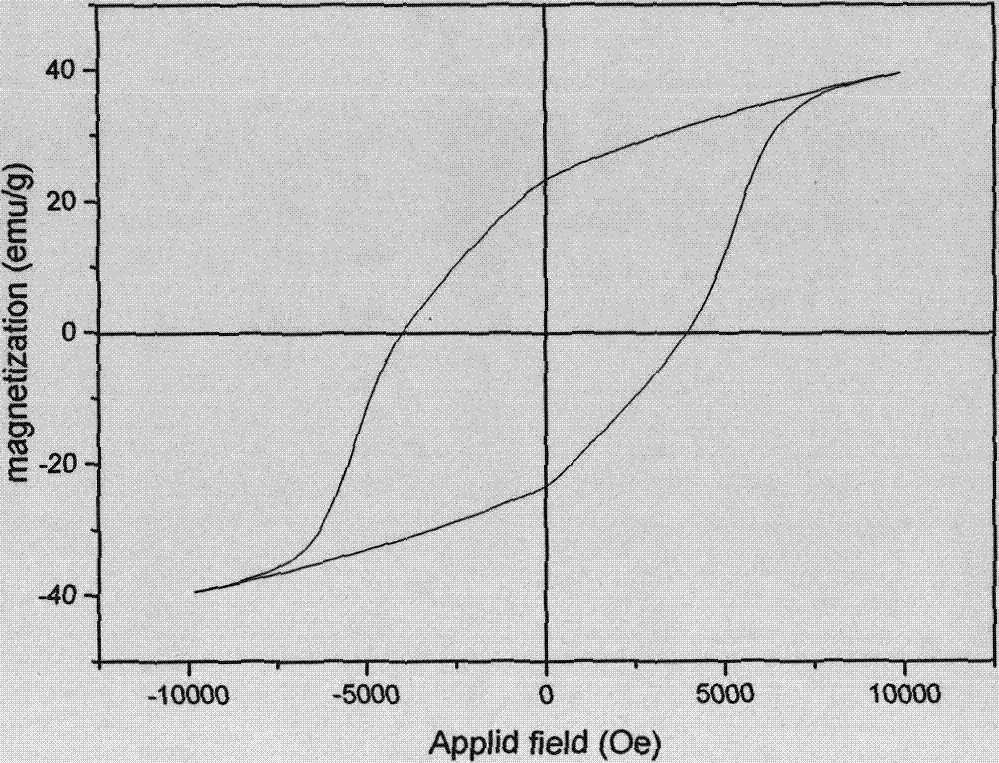

Embodiment 1

[0034] Weigh an appropriate amount of Fe(NO 3 ) 3 9H 2 O, Ba(NO 3 ) 2 Dissolve urea and urea in deionized water so that the molar concentrations of the three are 0.006mol / L, 0.0005mol / L, and 0.8mol / L respectively, weigh 0.5g of barium titanate powder that has been cleaned and degreased, and add it to 200ml of the above-mentioned In the reaction solution, 3wt% polyvinylpyrrolidone was added simultaneously as a dispersant. After the above solution was ultrasonically treated for 30 minutes, it was placed in an airtight container and reacted under stirring conditions. The reaction temperature was 100°C and the reaction time was 12 hours; Add ultrapure water to the supernatant to redisperse, then centrifuge, repeat the above process three times with deionized water first, and then with absolute ethanol, and put the coated precursor after cleaning and separation into a vacuum drying oven at 80°C Drying for 12 hours at 100°C; put the dried coating precursor into a muffle furnace...

Embodiment 2

[0036] Weigh an appropriate amount of Fe(NO 3 ) 3 9H 2 O, Ba(NO 3 ) 2 Dissolve urea and urea in deionized water so that the molar concentrations of the three are 0.006mol / L, 0.0005mol / L, and 0.8mol / L respectively. Weigh 0.1g of barium titanate powder that has been cleaned and degreased, and add it to 200ml of the above-mentioned In the reaction solution, 3wt% polyvinylpyrrolidone was added simultaneously as a dispersant. After the above solution was ultrasonically treated for 30 minutes, it was placed in an airtight container and reacted under stirring conditions. The reaction temperature was 100°C and the reaction time was 12 hours; Add ultrapure water to the supernatant to redisperse, then centrifuge, repeat the above process three times with deionized water first, and then with absolute ethanol, and put the coated precursor after cleaning and separation into a vacuum drying oven at 80°C Drying for 12 hours at 100°C; put the dried coating precursor into a muffle furnace...

Embodiment 3

[0038] Weigh an appropriate amount of Fe(NO 3 ) 3 9H 2 O, Ba(NO 3 ) 2 Dissolve urea and urea in deionized water so that the molar concentrations of the three are 0.024mol / L, 0.002mol / L, and 0.8mol / L respectively, weigh 0.5g of barium titanate powder that has been cleaned and degreased, and add it to 200ml of the above-mentioned In the reaction solution, 3wt% polyvinylpyrrolidone was added simultaneously as a dispersant. After the above solution was ultrasonically treated for 30 minutes, it was placed in an airtight container and reacted under stirring conditions. The reaction temperature was 90°C and the reaction time was 24 hours; Add ultrapure water to the supernatant to redisperse, then centrifuge, repeat the above process three times with deionized water first, and then with absolute ethanol, and put the coated precursor after cleaning and separation into a vacuum drying oven at 80°C Dry at 800°C for 12 hours; put the dried coating precursor into a muffle furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com