Method for assessing elastic modulus and strength of circular or circular-tube brittle material

A technology for brittle materials and elastic modulus, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the existing measurement methods cannot be used for the testing of elastic modulus and strength and other material properties, and have not been found. , to achieve quick evaluation, simple operation, saving test funds and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

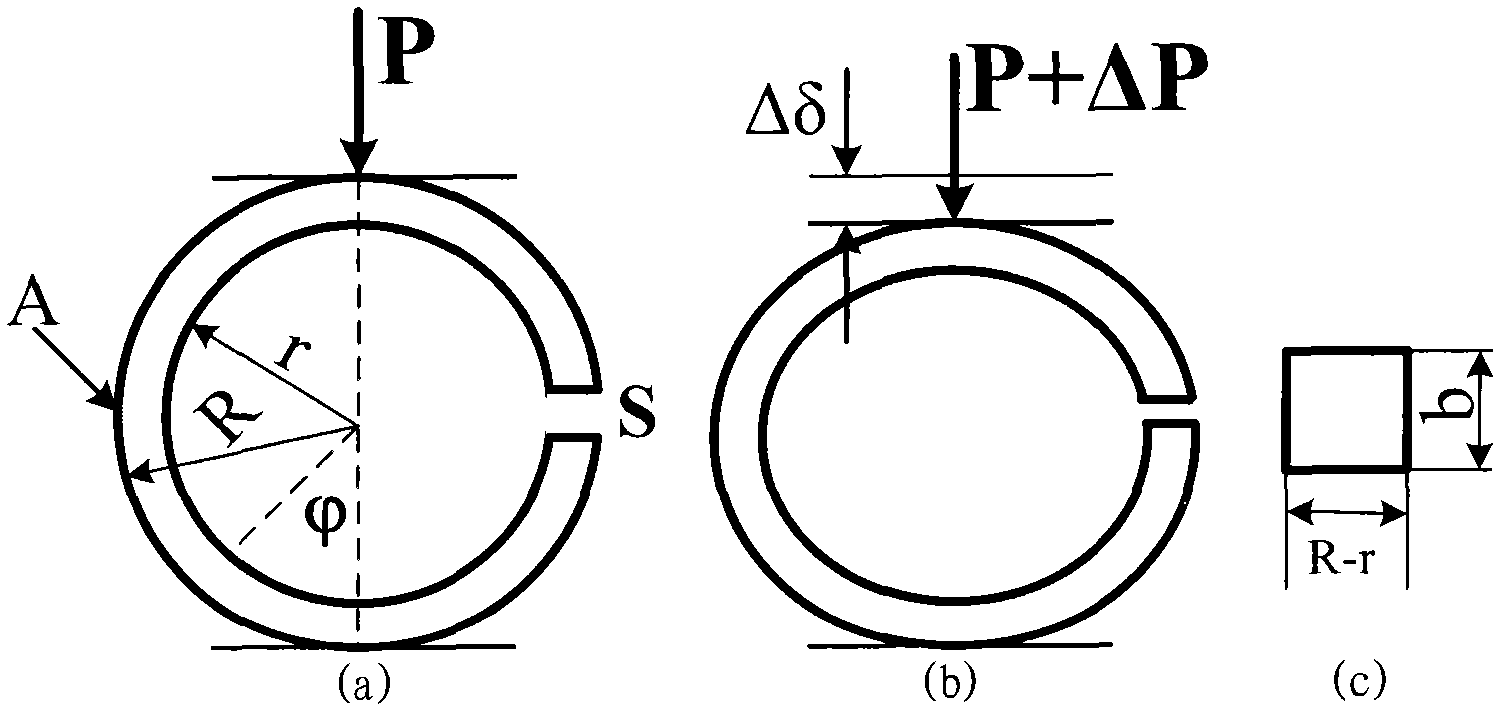

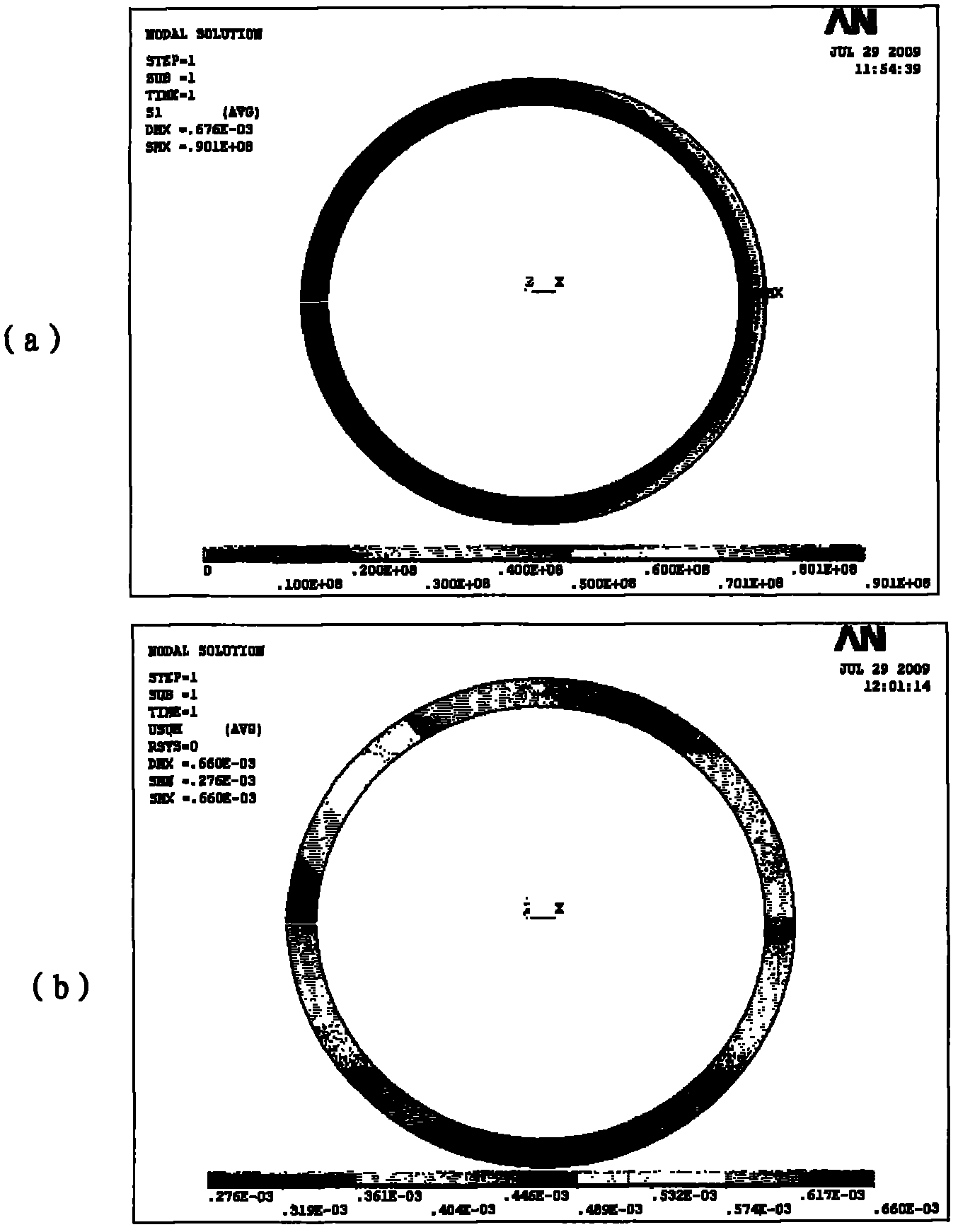

[0055] Embodiment 1: Measuring the elastic modulus and strength of the glass circular tube at room temperature

[0056] The specific operation process is:

[0057] 1) Select a glass circular tube with an inner diameter of 15.70mm (inner radius r is 7.85mm) and an outer diameter of 17.74mm (outer radius R is 8.87mm) as the research object, and cut it into a circle with a width of 3.94mm Ring, grind and polish the side of the ring, and then use a diamond blade to cut a gap of about 2mm to form a gap ring glass sample;

[0058] 2) Fix the notched ring glass sample on the support table of the universal testing machine, and the notch is located at half of the height direction of the sample;

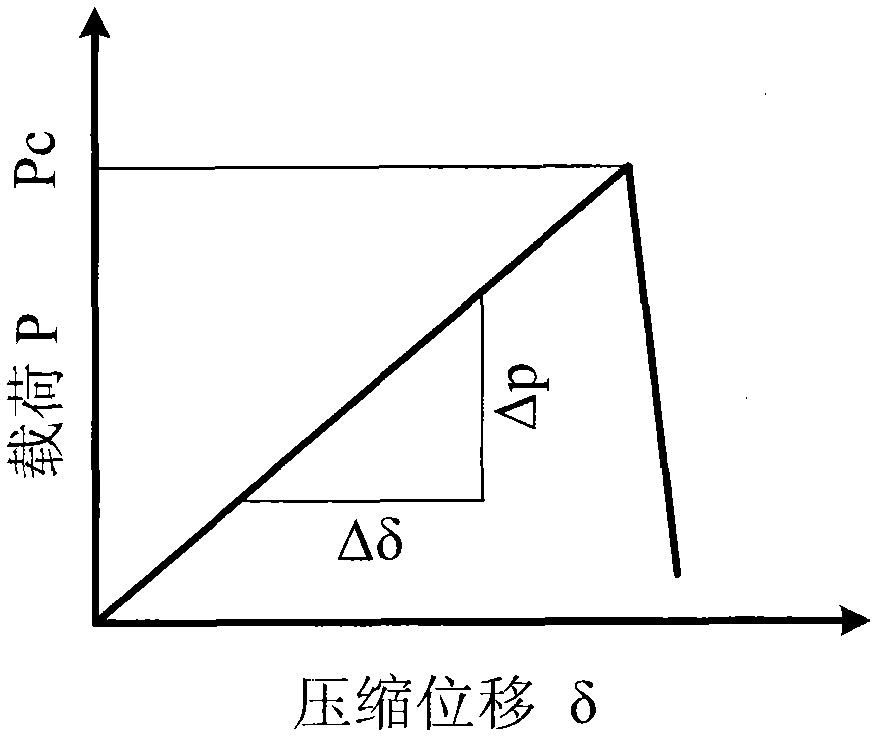

[0059] 3) Load the notched ring sample at a speed of 0.5 mm / min until the sample breaks, and use an inductance meter to record the compression amount Δδ of the sample in the direction of force application. Record that the critical load corresponding to the fracture of the sample is 6.76N, th...

Embodiment 2

[0062] Embodiment 2: measure aluminum oxide (Al 2 o 3 ) Elastic modulus and strength of ceramic tubes in different temperature ranges

[0063] The specific operation process is:

[0064] 1) When measuring the elastic modulus and strength at high temperature, the upper indenter and the supporting platform are both made of SiC. The upper indenter of the compression device is directly in contact with the sample support platform, which is used to calibrate the measurement error of the compression amount introduced by the fixture of the testing machine during the loading process. In this experiment, reach the test temperature and keep it warm for a period of time (generally 15 minutes) to keep the internal and external temperature of the sample consistent. Apply a load to 500N. The maximum load value can also be adjusted appropriately according to the load capacity of the test sample and the fixture. The loading rate is 0.5mm / min, record the load-displacement curve at this temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com