Medicinal composition containing ibuprofen and arginine and preparation method and application thereof

A composition and technology of arginine, applied in the field of medicine, can solve problems such as increased production cost and cycle, slow progress in the development of liquid preparations, and limited solubility of ibuprofen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1 ibuprofen injection

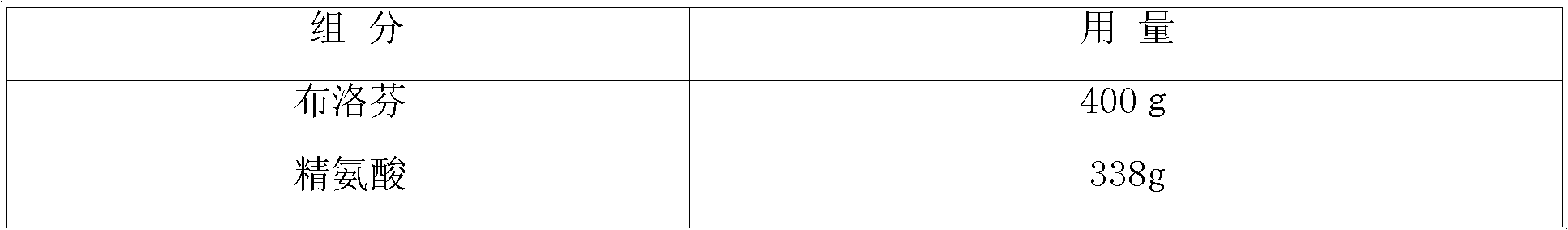

[0008] prescription:

[0009] components

Dosage

ibuprofen

400g

arginine

338g

pH

7.4

Water for Injection

q.s 4000ml

Co-made

1000 bottles or 8000 bottles

[0010] Preparation:

[0011] Take about 3200ml of water for injection, add arginine, stir to dissolve, add Dexibuprofen, stir to dissolve, add water to 4000ml, filter, and pack into ampoules.

Embodiment 2

[0012] Embodiment 2 ibuprofen injection

[0013] prescription:

[0014] components

Dosage

ibuprofen

800g

arginine

676g

pH

7.4

Water for Injection

q.s 8000ml

Co-made

1000 bottles or 400 bottles

[0015] Preparation:

[0016] Take about 3200ml of water for injection, add arginine, stir to dissolve, add ibuprofen, stir to dissolve, add water to 4000ml, filter, and pack into ampoules.

Embodiment 3

[0017] Embodiment 3: Ibuprofen freeze-dried powder injection

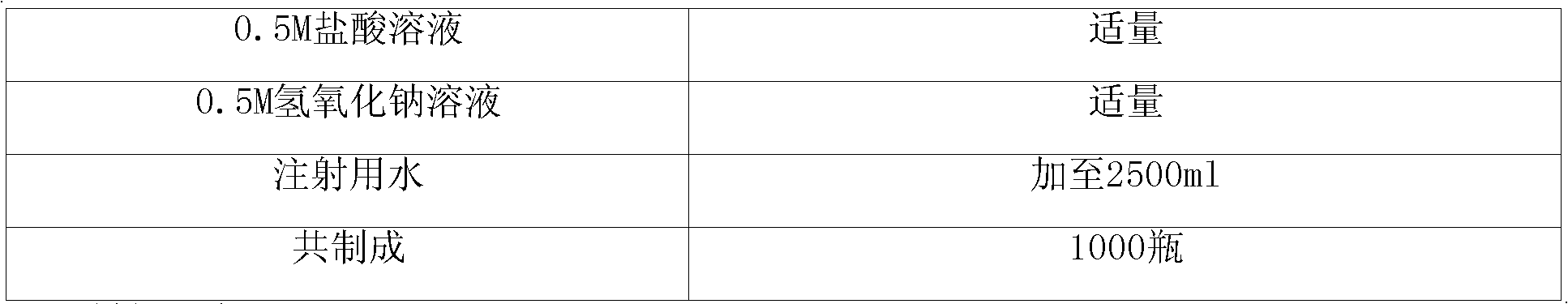

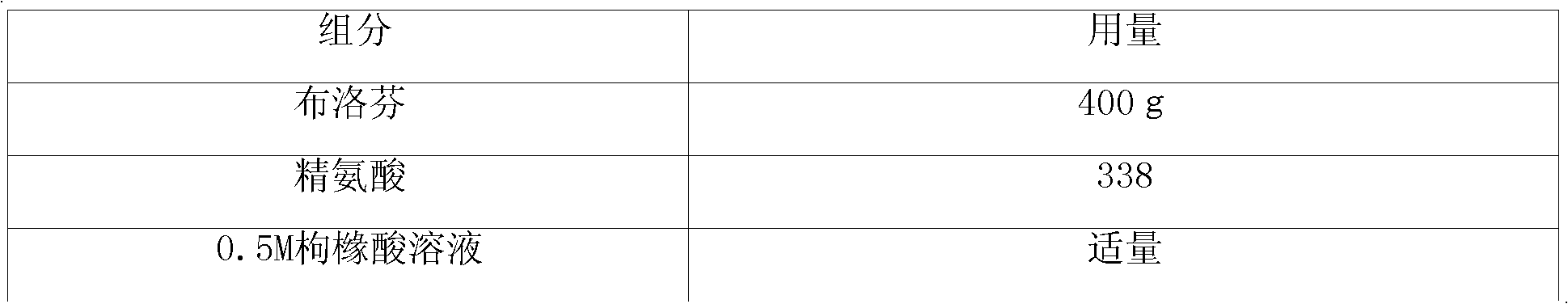

[0018] prescription:

[0019]

[0020]

[0021] Preparation:

[0022] Take 1250ml of water for injection, add the prescribed amount of ibuprofen and arginine, stir and dissolve, adjust the pH value to 6.5-7.5 with hydrochloric acid solution and sodium hydroxide solution, add 0.1% active carbon for injection according to the prepared amount, and heat the liquid medicine to about Stir at 60°C for 20 minutes, filter and decarburize, add water for injection to the total amount, and detect intermediates. After the intermediates pass the test, fine filter with a 0.22 μm microporous membrane, fill in vials, place the vials in a freeze dryer, and freeze dry.

[0023] Freeze-drying conditions: Pre-freeze at -40°C for 4 hours, heat up to -10°C in the first stage for 2 hours, vacuum dry for 20 hours, heat up in the second stage from -10°C to 30°C within 1 hour, and keep warm for 4 Hour.

[0024] After freeze-drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com