High-stability fuel-cell catalyst modified by oxide and preparation method thereof

A fuel cell, high-stability technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the low stability of transition metal cluster chalcogenides, Restrict the application of fuel cells and other issues to achieve the effects of reducing corrosion and shedding, improving metal utilization, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

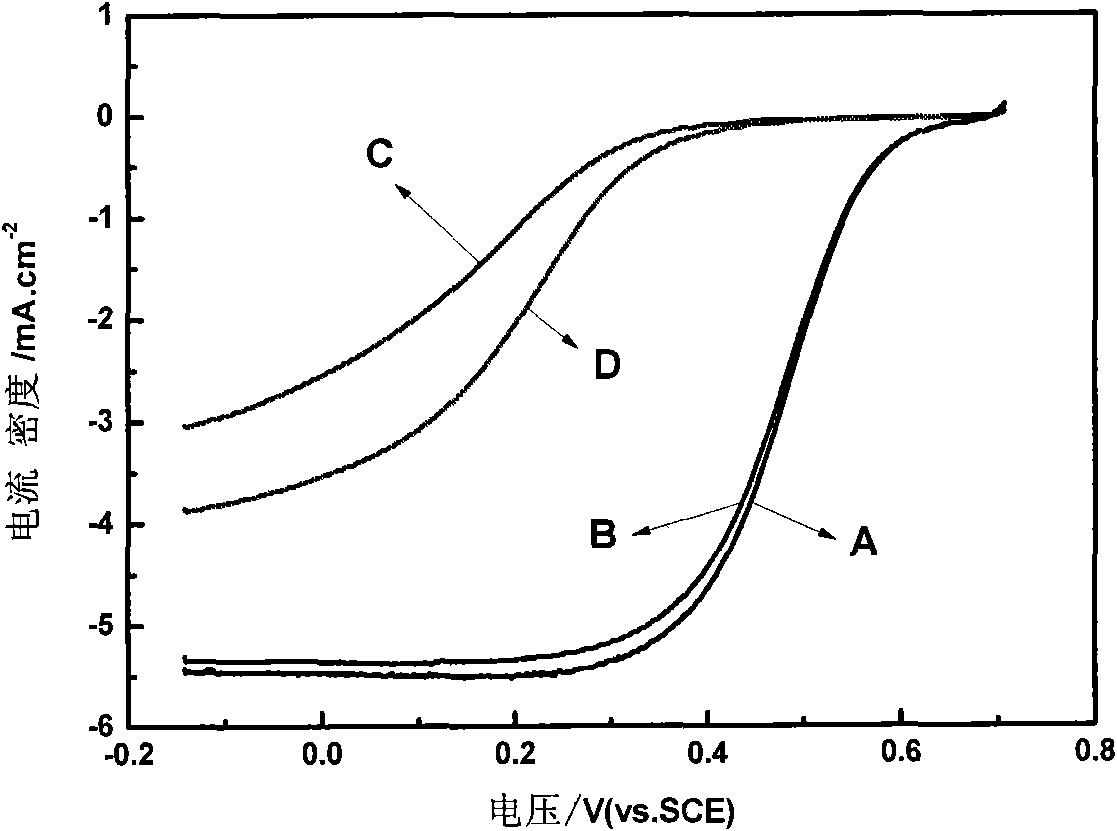

Embodiment 1

[0048] 1) Add 2ml ZrO(NO 3 ) 2 (10mg Zr / ml) aqueous solution was added to a 250ml beaker, then a mixture of 30ml ethanol and 20ml water was added, stirred evenly by ultrasonic, then 405.2mg XC-72 carbon powder was added, and mixed into a uniform slurry. Put this beaker into a water bath at 60°C, stir, and evaporate the solvent to dryness. The resulting black powder was heat-treated at 300°C in air for 3 hours to obtain ZrO 2 / C composite carrier.

[0049] 2) A. Accurately weigh 100 mg of the above-mentioned composite carrier, add it into 30 ml of ethylene glycol, and stir it ultrasonically to form a uniform slurry. Dilute 6.6ml RuCl3 (3.63mg Ru / ml) ethylene glycol solution and 1ml Na 2 SeO 3 (2.99mg Se / ml) solution was added to 50ml ethylene glycol, ultrasonically mixed evenly, added 2mol / L NaOH ethylene glycol solution, adjusted the pH value to 8, and microwaved for 2min. Add the homogeneous slurry of composite carrier while hot. The temperature was lowered to room tem...

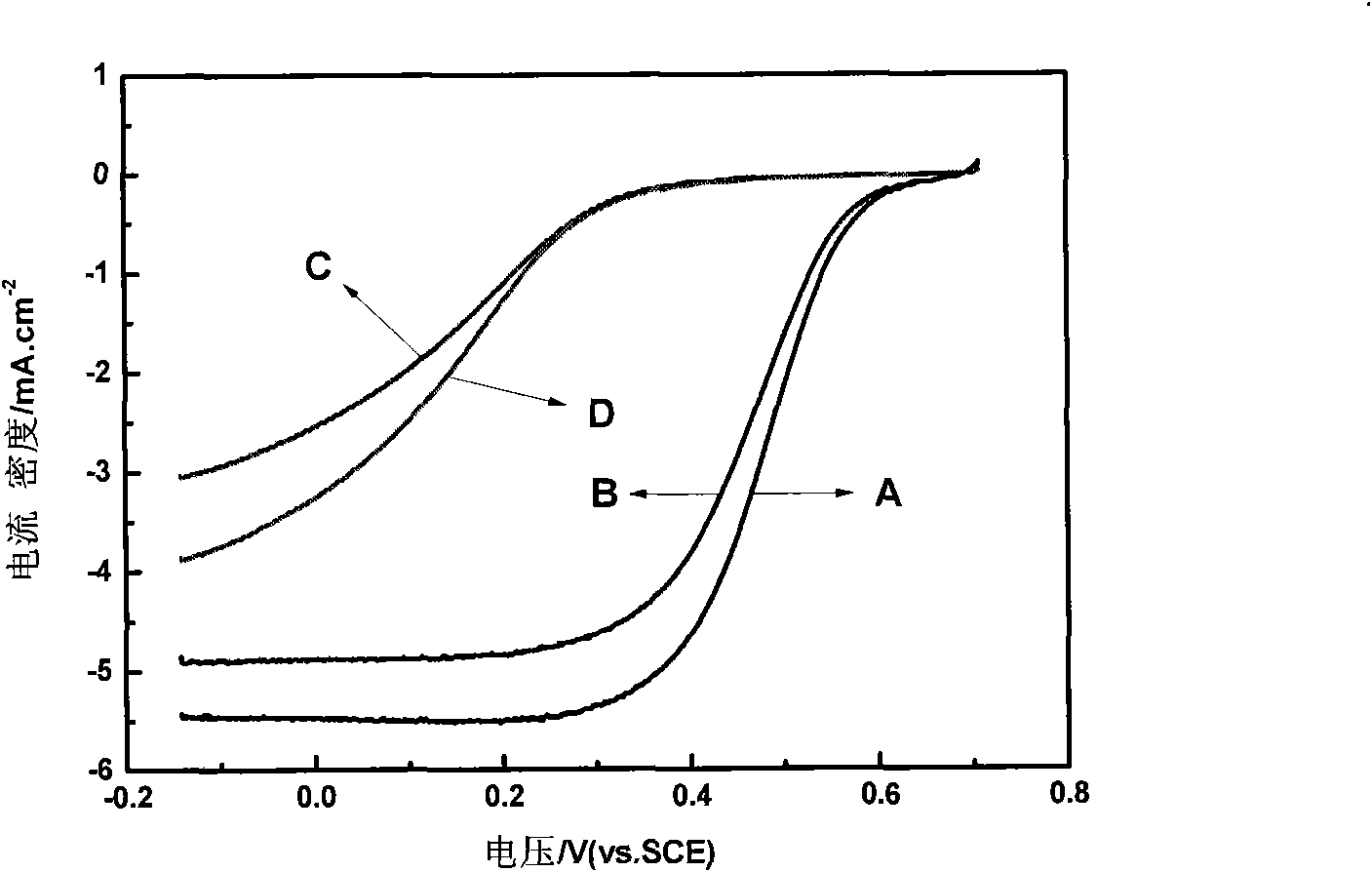

Embodiment 2

[0057] 1) Add 0.5ml ZrO(NO 3 ) 2 (10mg Zr / ml) aqueous solution was added to a 250ml beaker, then a mixture of 30ml ethanol and 20ml water was added, ultrasonically stirred evenly, then 263.3mg XC-72 carbon powder was added, and mixed into a uniform slurry. Put this beaker into a water bath at 60°C, stir, and evaporate the solvent to dryness. The resulting black powder was heat-treated at 300°C in air for 3 hours to obtain ZrO 2 / C composite carrier.

[0058] 2) A. Accurately weigh 100 mg of the above-mentioned composite carrier, add it into 30 ml of ethylene glycol, and stir it ultrasonically to form a uniform slurry. 6.9ml RuCl 3 Add (3.63mg Ru / ml) ethylene glycol solution into 50ml ethylene glycol, mix well by ultrasonic, add 2mol / L NaOH ethylene glycol solution, adjust the pH value to 8, and heat in microwave for 2min. Add the homogeneous slurry of composite carrier while hot. The temperature was lowered to room temperature, the pH value was adjusted to 4 with HCl sol...

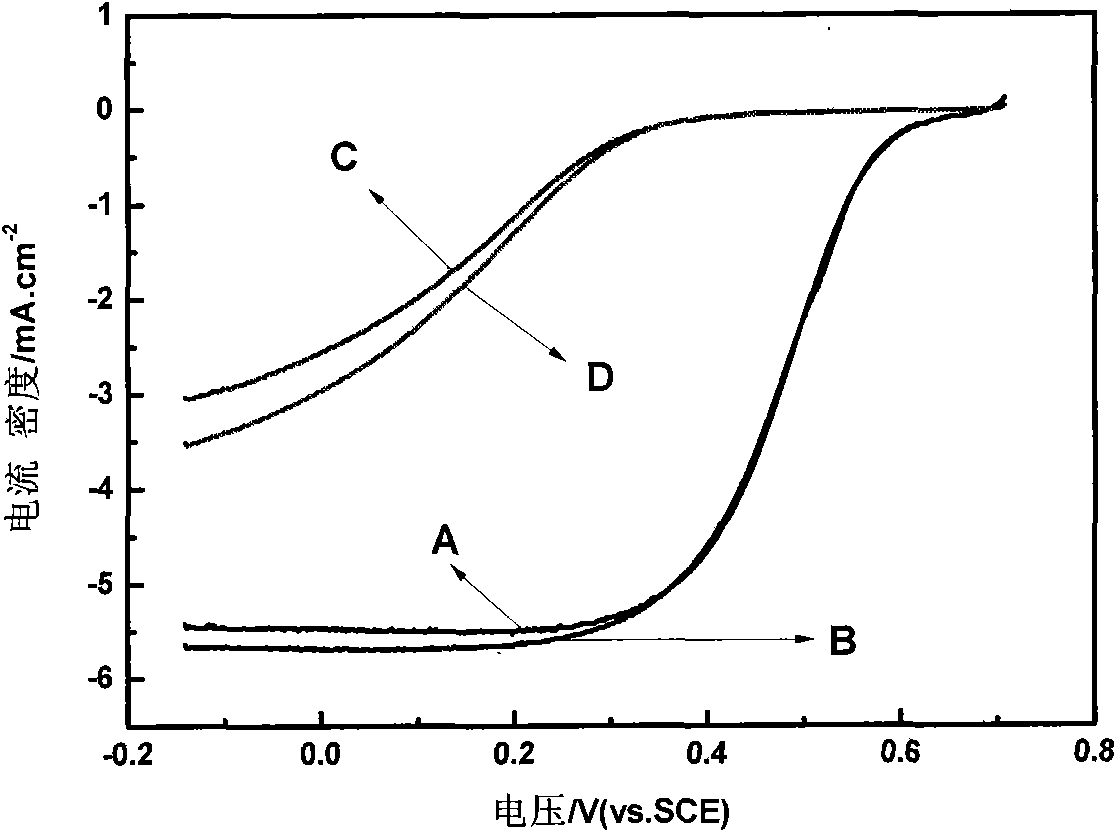

Embodiment 3

[0063] 1) Add 0.5ml ZrO(NO 3 ) 2 (10mg Zr / ml) aqueous solution was added to a 250ml beaker, then a mixture of 30ml ethanol and 20ml water was added, ultrasonically stirred evenly, then 263.3mg BP2000 carbon powder was added, and mixed into a uniform slurry. Put this beaker into a water bath at 60°C, stir, and evaporate the solvent to dryness. The resulting black powder was heat-treated at 300°C in air for 3 hours to obtain ZrO 2 / C composite carrier.

[0064] 2) A. Accurately weigh 200 mg of the above-mentioned composite carrier, add it into 60 ml of ethylene glycol, and stir it ultrasonically to form a uniform slurry. 6.9ml RuCl 3 (3.63mg Ru / ml) ethylene glycol solution was added to 50ml ethylene glycol, and ultrasonically mixed evenly, and 2mol / L NaOH ethylene glycol solution was added to adjust the pH value to 9, and microwaved for 2min. Add the homogeneous slurry of composite carrier while hot. The temperature was lowered to room temperature, the pH value was adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com