Bipolar transistor

A technology of bipolar transistors and transistors, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of large device area, high cost, and complex deep trench isolation process, etc., to reduce the device area and reduce parasitic effects , the effect of reducing the number of photolithography layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

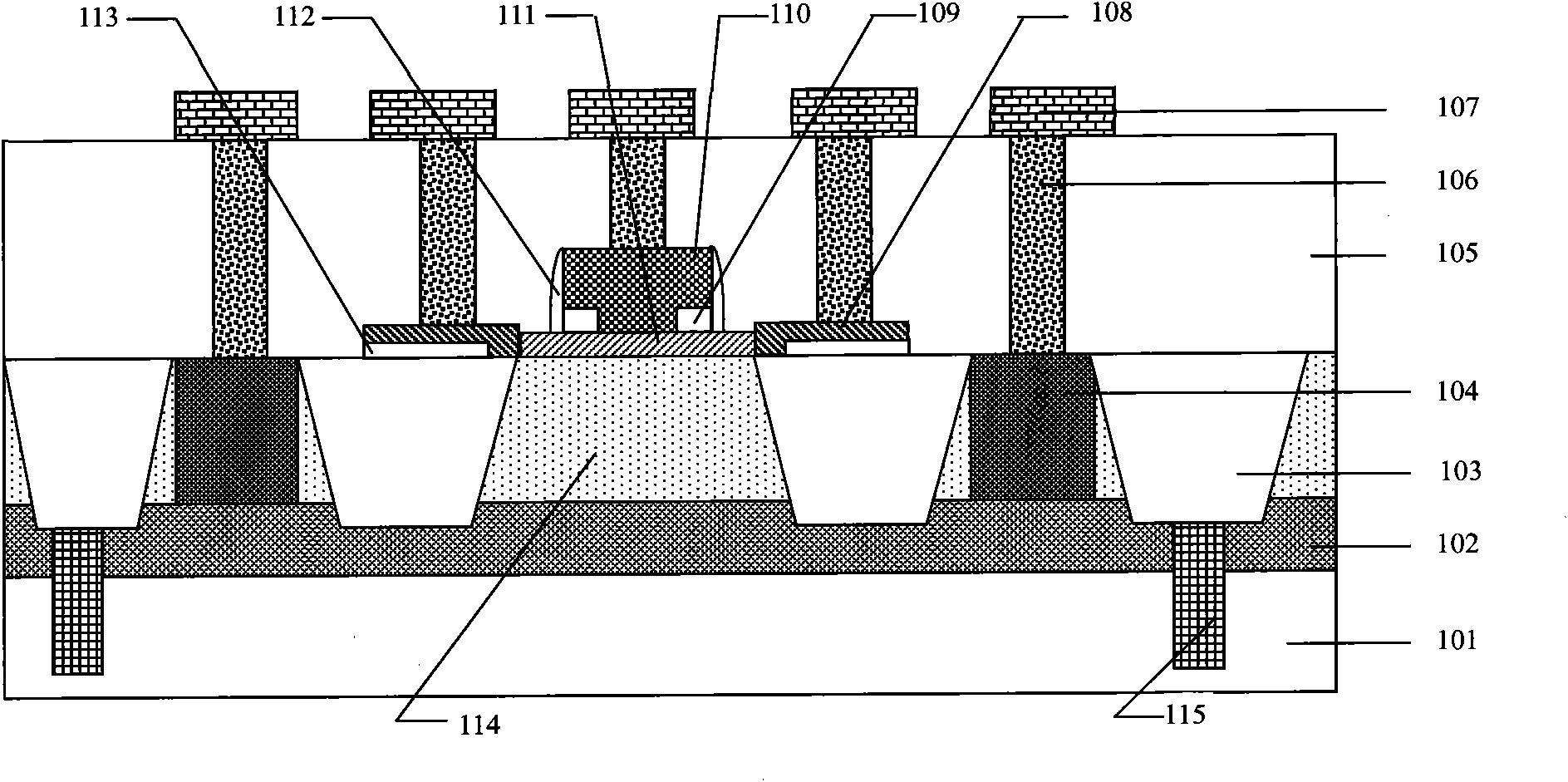

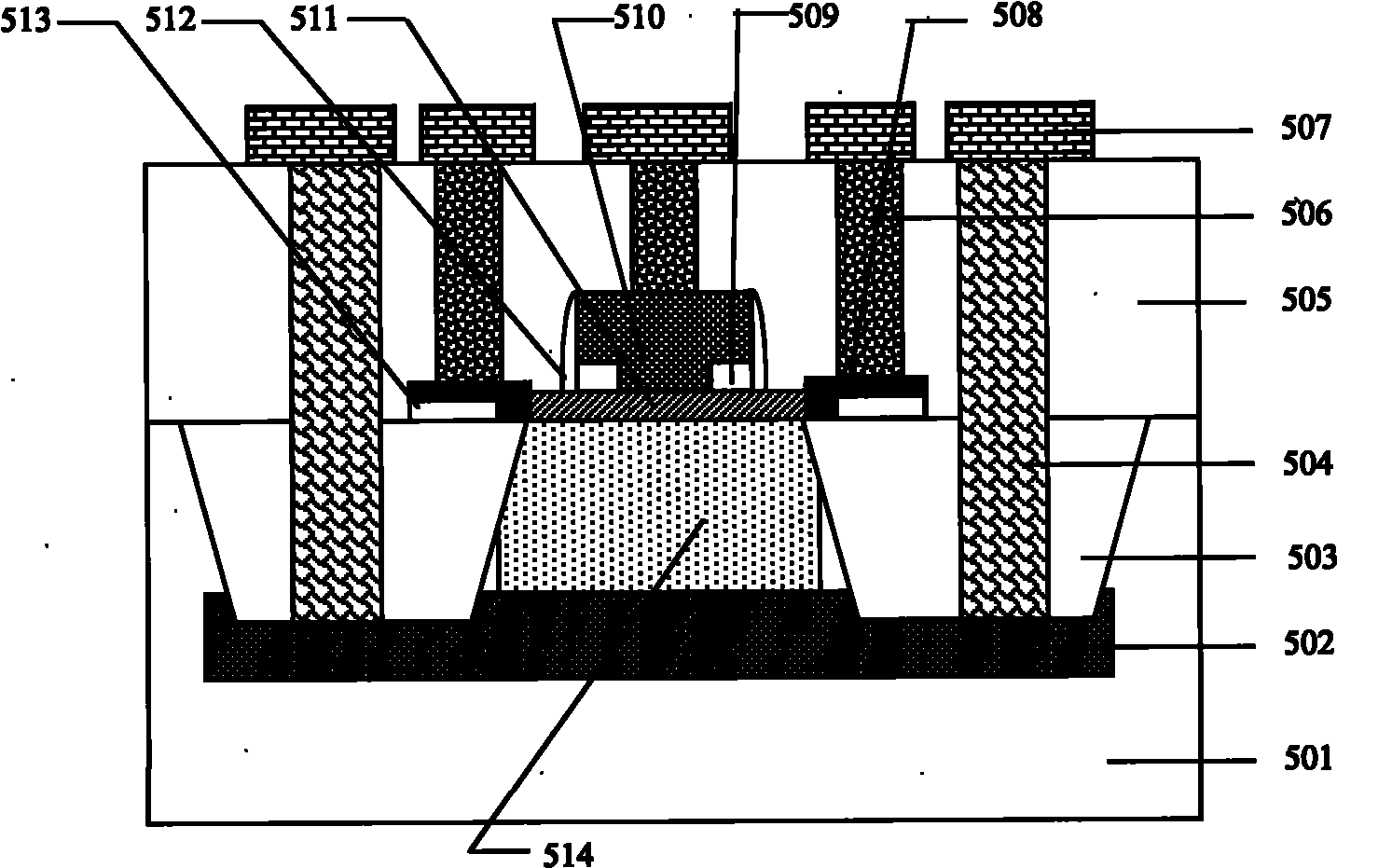

[0017] Such as figure 2 As shown, it is a schematic diagram of the device structure of the bipolar transistor of the present invention. An active region isolated by a shallow trench field oxygen 503 is formed on a silicon substrate 501. The bipolar transistor includes: a collector region 514, a base region 511, A launch area 510 .

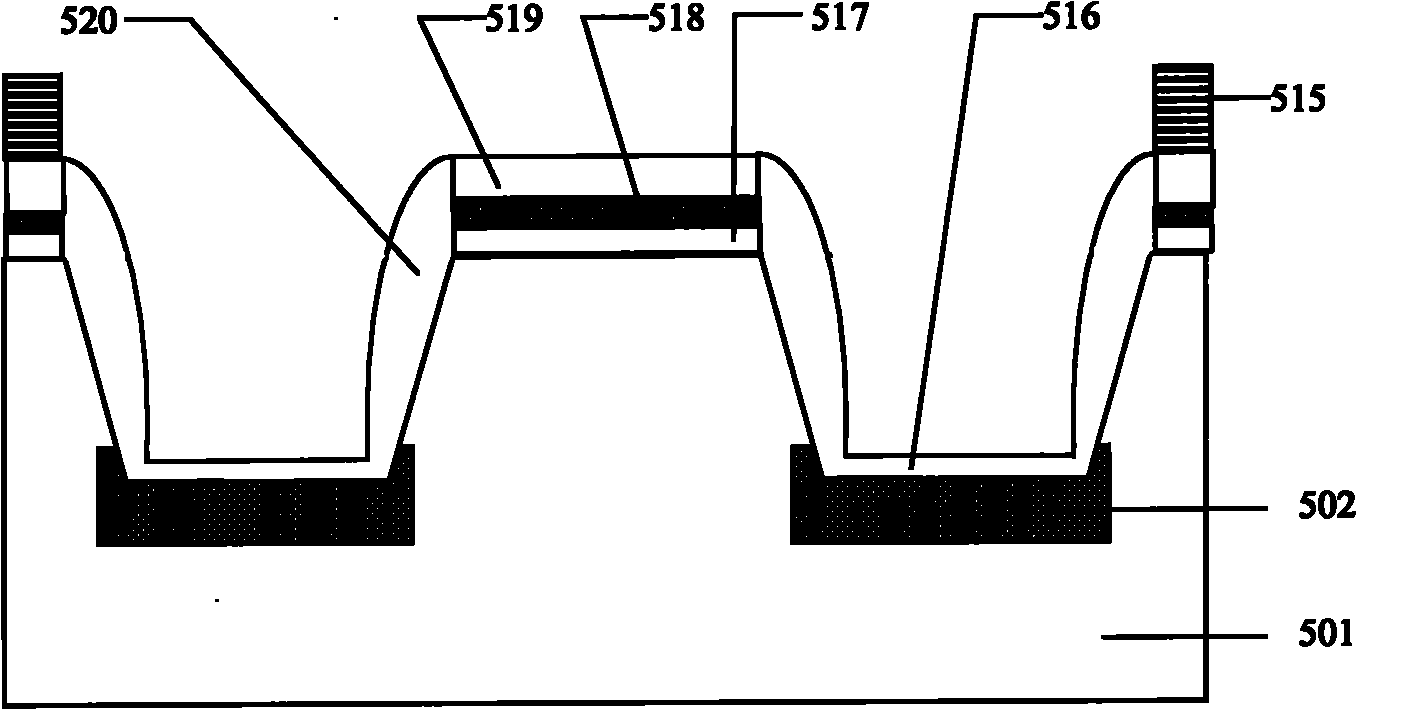

[0018] The collector region 514 is formed by performing single-step or multi-step implantation of impurity ions of the first conductivity type in the active region. The bottom of the collector region 514 is connected to a buried layer formed by connecting two pseudo-buried layers 502 at the bottom of shallow grooves on both sides of the active region; when the active region is smaller than 0.5 microns, the two pseudo-buried layers 502 Intersect in the active region by lateral diffusion to form the buried layer of the collector region 514; when the active region is greater than 0.5 microns, implant at the same depth as the two pseudo-buried layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com