Microbial feed additives and preparation method thereof

A technology of microbial feed and additives, applied in the field of microbial fermentation, can solve problems such as the decline of livestock and meat varieties, the increase of bacterial resistance, and the impact on human health, so as to improve immunity, reduce breeding costs, and alleviate intestinal flora. unbalanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

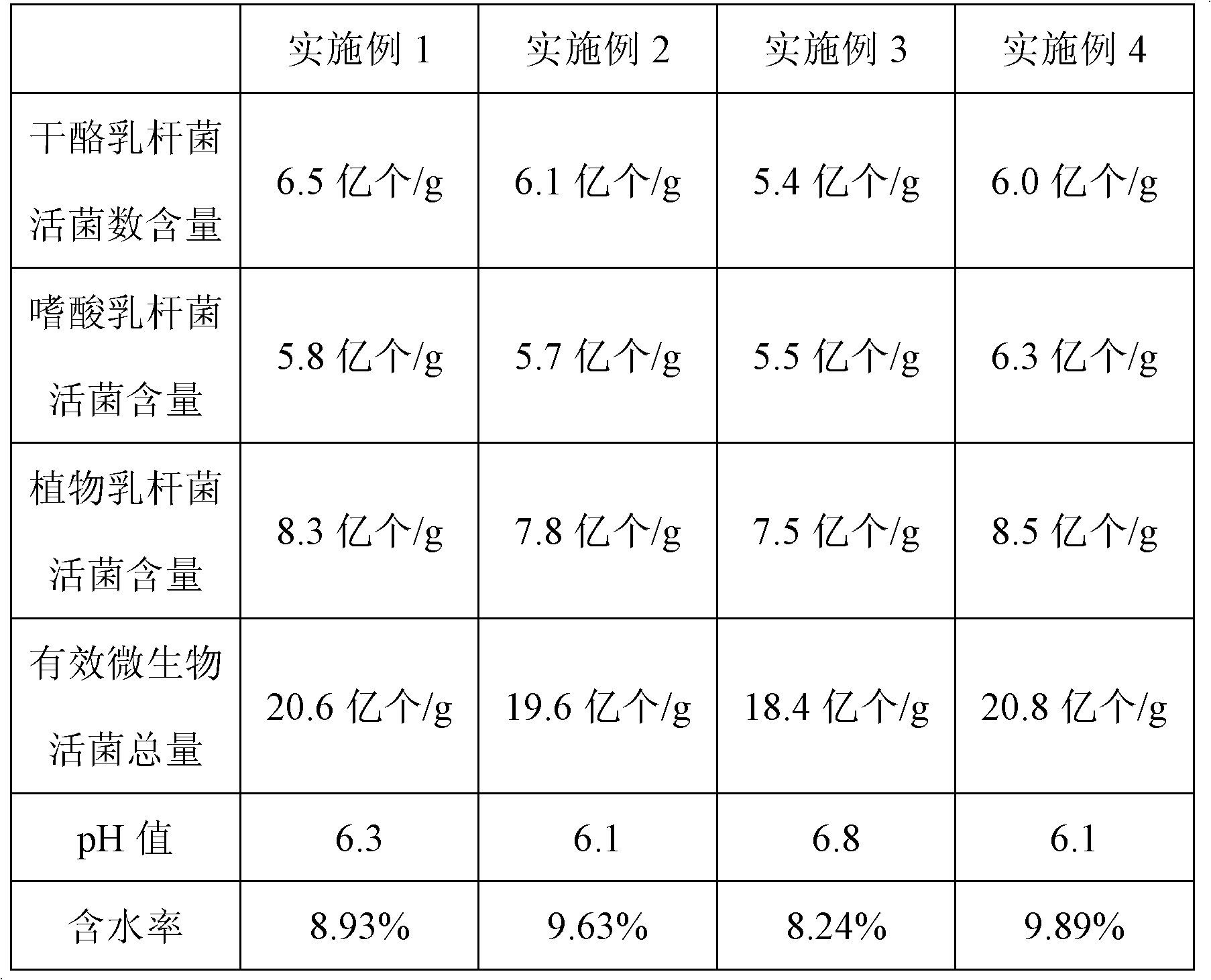

Embodiment 1

[0026] (1) Separating, purifying and fermenting the components of each bacterial strain, making the corresponding culture solution for subsequent use;

[0027] (2) Get Lactobacillus casei fermented liquid 970mL, Lactobacillus acidophilus fermented liquid 920mL, Lactobacillus plantarum fermented liquid 1160mL carry out fully mixing, make total amount and be the mixed fermented liquid of 3050mL, the ratio of the three is 1: 0.95: 1.20;

[0028] (3) Take 3850g food-grade cornstarch, 200g white sugar, and 350g brown sugar to fully mix to make a carrier with a total amount of 4400g, wherein the proportion of sugars is (200+350) / (3850+200+350)=12.5 %;

[0029] (4) fully mixing the mixed fermentation broth of (2) and the adsorption carrier of (3), the volume-to-mass ratio of the fermentation broth to the adsorption carrier is 3050:4400=1:1.44;

[0030] (5) Put the above mixture into a low-temperature drying equipment for continuous drying at low temperature, take it out after 8 hour...

Embodiment 2

[0032] (1) Separating, purifying and fermenting the components of each bacterial strain, making the corresponding culture solution for subsequent use;

[0033] (2) Get Lactobacillus casei fermented liquid 1125mL, Lactobacillus acidophilus fermented liquid 1000mL, Lactobacillus plantarum fermented liquid 1425mL carry out fully mixing, make total amount and be the mixed fermented liquid of 3550mL, three ratios are 1: 0.89: 1.27;

[0034] (3) Take 4150g food-grade cornstarch, 350g white sugar, and 350g brown sugar to fully mix to make a carrier with a total amount of 4850g, wherein the proportion of sugars is (350+350) / (4150+350+350)=14.43 %;

[0035] (4) fully mixing the mixed fermentation broth of (2) and the adsorption carrier of (3), the volume-mass ratio of the fermentation broth to the adsorption carrier is 3550:4850=1:1.366;

[0036] (5) Put the above mixture into a low-temperature drying equipment for low-temperature continuous drying, take it out after 7 hours and 51 mi...

Embodiment 3

[0038] (1) Separating, purifying and fermenting the components of each bacterial strain, making the corresponding culture solution for subsequent use;

[0039] (2) Get Lactobacillus casei fermented liquid 1000mL, Lactobacillus acidophilus fermented liquid 1125mL, Lactobacillus plantarum fermented liquid 1350mL are fully mixed, make total amount and be the mixed fermented liquid of 3475mL, three ratios are 1: 1.13: 1.35;

[0040] (3) Get 3980g food grade cornstarch and 410g syrup to fully mix to make a carrier with a total amount of 4390g, wherein the proportion of carbohydrates is 410 / (3980+410)=9.34%;

[0041] (4) fully mixing the mixed fermentation broth of (2) and the adsorption carrier of (3), the volume-to-mass ratio of the fermentation broth to the adsorption carrier is 3475:4390=1:1.263;

[0042] (5) Put the above mixture into a low-temperature drying equipment for low-temperature continuous drying, take it out after 8 hours and 43 minutes, the measured moisture content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com