Method for extracting water-soluble alpha-glucosidase inhibitor

A technology of glucosidase and extraction method, which is applied in the directions of drug combination, medical raw materials derived from fungi, metabolic diseases, etc., can solve the problems of low application safety, not directly involved in the inhibitory function of α-glucosidase, etc., and achieves safety High, less toxic and side effects, good active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

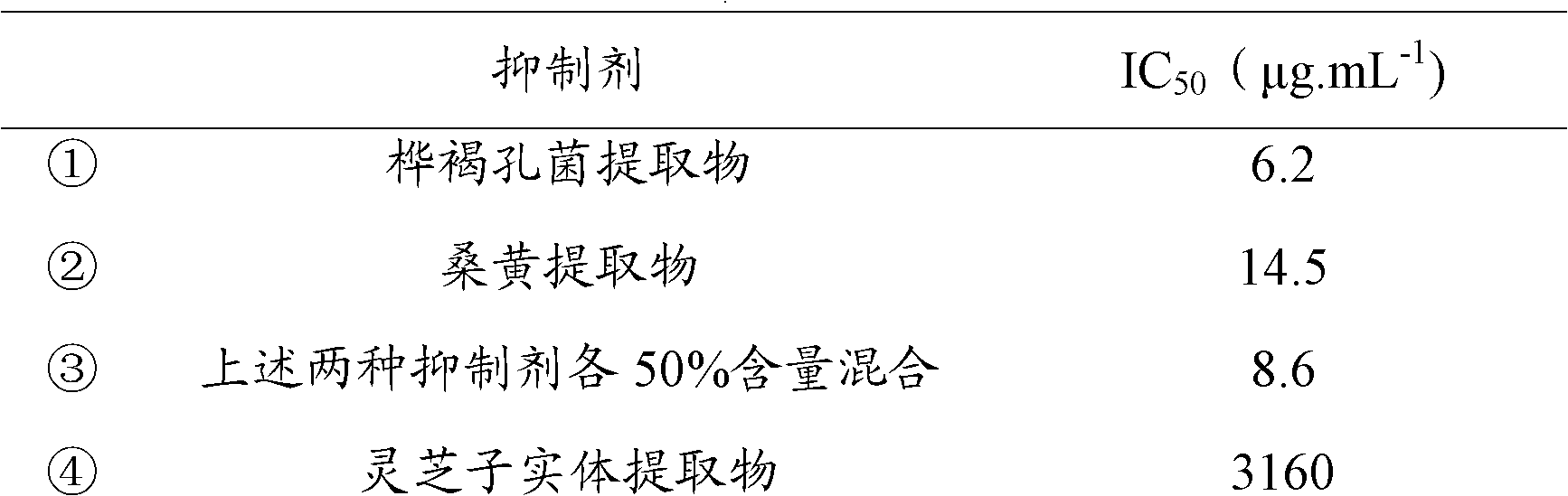

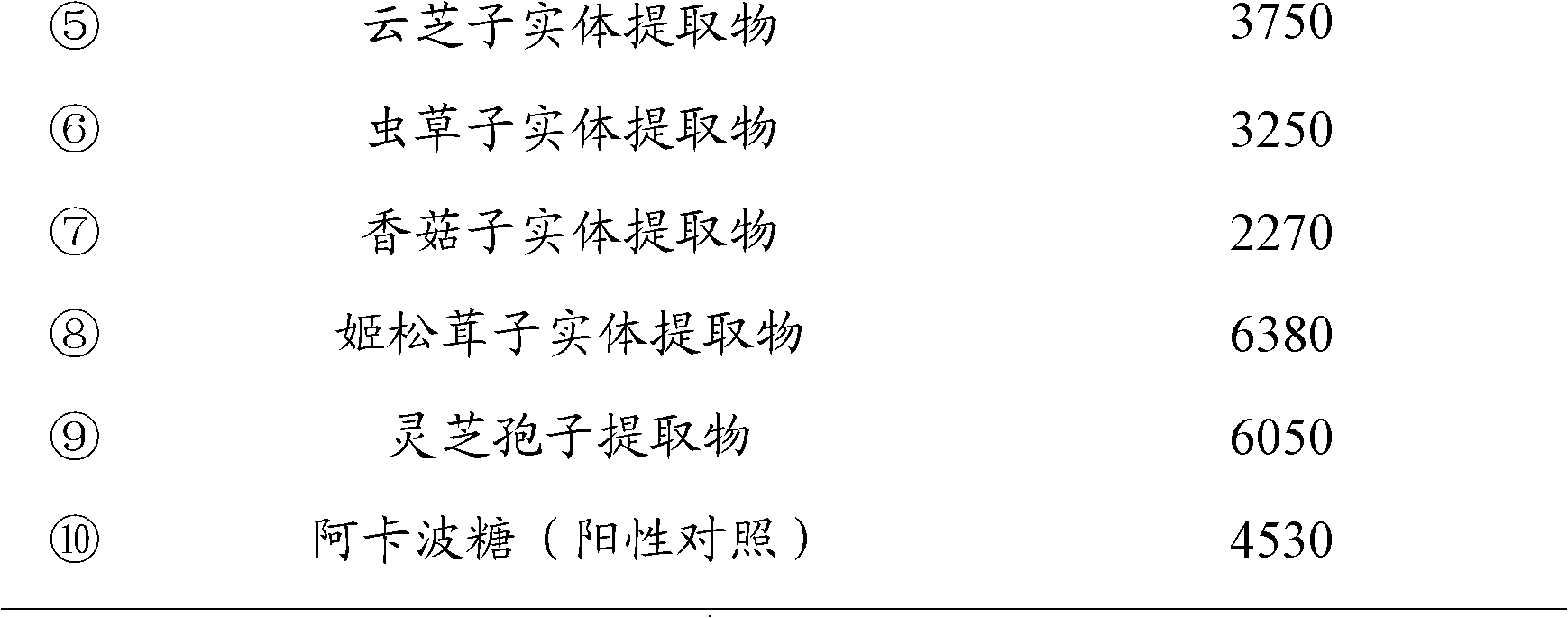

Method used

Image

Examples

Embodiment 1

[0034] Inonotus obliquus fruiting bodies → crushed and sieved to 80 mesh → weigh 100g → add 3000mL water → ultrasonic treatment (Shanghai Shengxi Ultrasonic Instrument Co., Ltd., FS1200PV ultrasonic processor, 20KHz, 360W) for 30 minutes → add 1mL liquid high temperature α- Amylase (20,000 U.mL -1 , Zaozhuang Jienuo Bioenzyme Co., Ltd.), boiling water extraction for 3h→5400g centrifugation to remove slag→vacuum concentration of the supernatant (pressure below 0.08Mpa, temperature 45℃~60℃, the same below) to the original 1 / 15 volume→add 95% ethanol to a final concentration of 80%, ethanol precipitation for 8h → precipitation plus 2000mL distilled water to redissolve → 10,000 molecular weight cut-off membrane (Millipore, USA, labscale TFF system, PXB010A50 polyethersulfone 10KD ultrafiltration membrane bag) ultrafiltration for 24h → filtrate vacuum concentration (pressure 0.08Mpa below, temperature 45 ℃ ~ 60 ℃, the same below) to 30mL → freeze-drying → 10.2g Inonotus obliquus wa...

Embodiment 2

[0036] Inonotus obliquus fruiting bodies → smashed and sieved to 60 mesh → weighed 100g → added 3000mL water → ultrasonic (20KHz, 360W) treatment for 30 minutes → added liquid high-temperature α-amylase (20,000 U.mL) with a raw material weight of 0.8mL -1 ), extract with boiling water for 3 hours→3800g centrifuge to remove slag→vacuum concentrate the supernatant to the original 1 / 10 volume→add 95% ethanol to the final concentration of 80%, ethanol precipitation for 8h→precipitate add 1500mL distilled water to redissolve→10,000 molecular weight cut-off membrane Ultrafiltration for 12 hours → vacuum concentration of the filtrate to 30 mL → freeze drying → 11.3 g of Inonotus obliquus water-soluble α-glucosidase inhibitor (polysaccharide content 21.6%) → semi-inhibitory activity IC of α-glucosidase 50 =7.1 μg / mL.

Embodiment 3

[0038] Inonotus obliquus fruiting bodies → crushed and sieved to 100 mesh → weigh 100g → add 4000mL water → ultrasonic (20KHz, 360W) treatment for 40 minutes → add 1mL liquid high temperature α-amylase (20,000 U.mL -1 ), boiling water extraction for 4 hours→5400g centrifugation to remove slag→supernatant concentrated in vacuum to 1 / 10 of the original volume→add 95% ethanol to final concentration of 80%, ethanol precipitation for 8h→precipitate plus 3000mL distilled water to redissolve→10,000 molecular weight cut-off membrane Ultrafiltration for 24 hours → vacuum concentration of the filtrate to 40 mL → freeze drying → 11.6 g of Inonotus obliquus water-soluble α-glucosidase inhibitor (polysaccharide content 23.4%) → semi-inhibitory activity IC of α-glucosidase 50 = 6.5 μg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com