Distillation and purification method of o-nitroethylbenzene

A technology of o-nitroethylbenzene and a purification method, which is applied in the field of refining and purification of chemical products, can solve problems such as volatilization, and achieve the effects of high yield, simple equipment, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

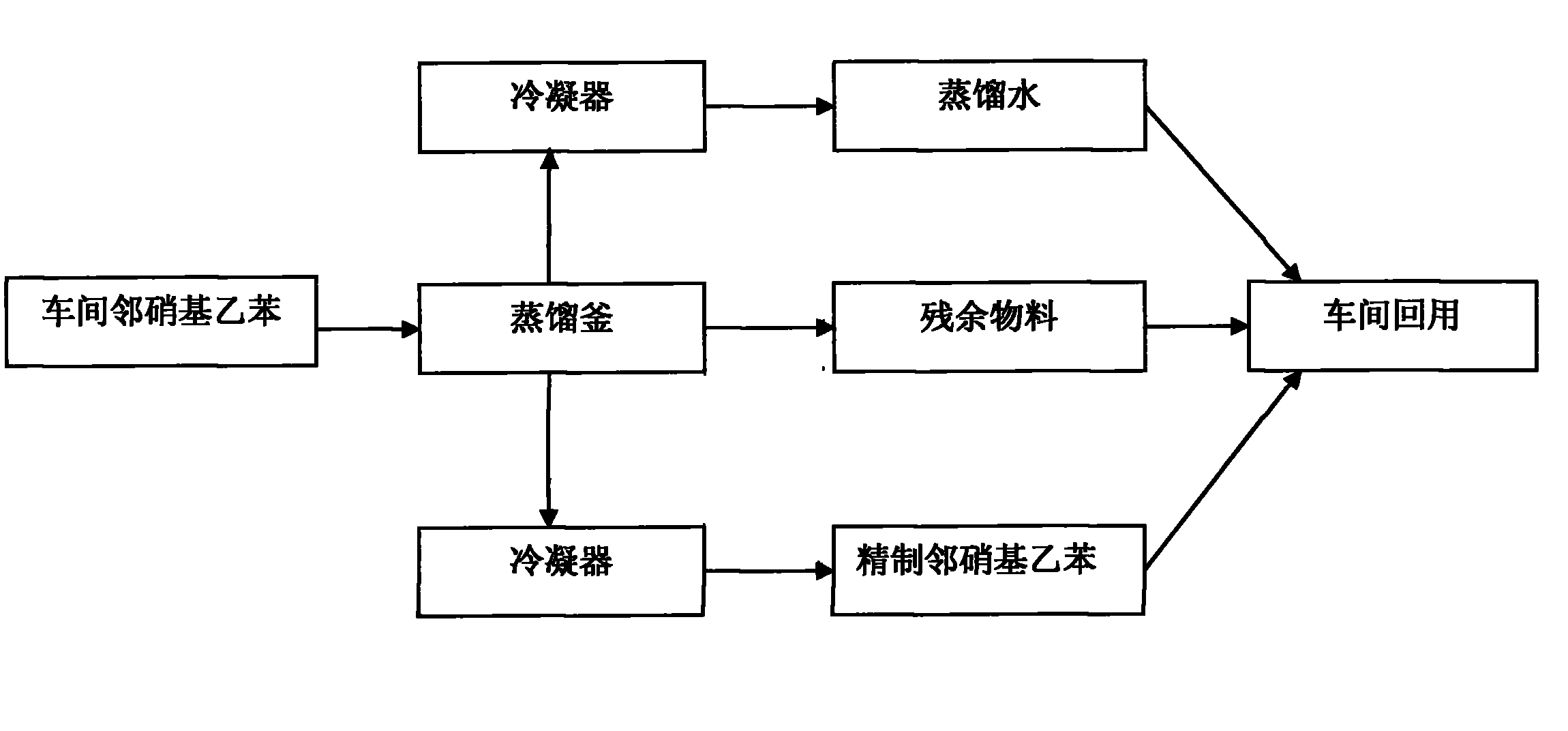

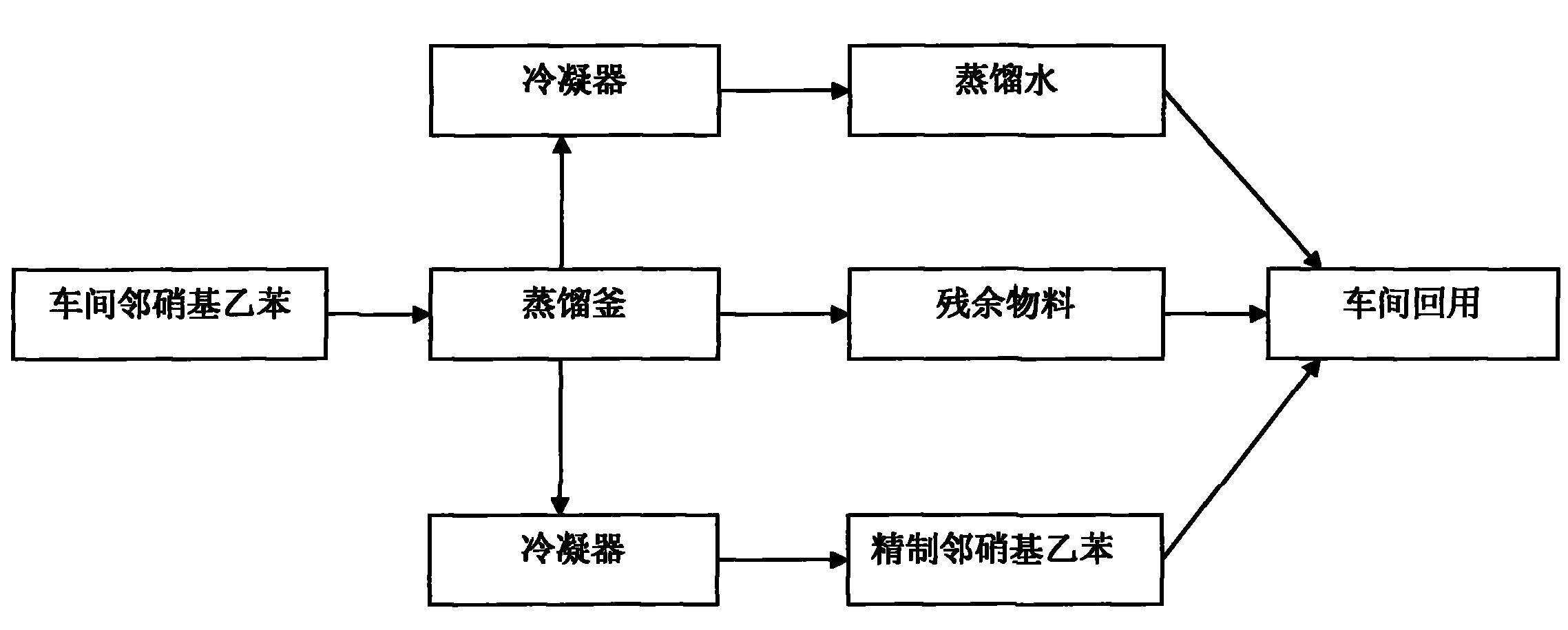

Image

Examples

Embodiment Construction

[0013] 1. Distillation and purification equipment: one 7000L still, one double-effect stainless steel tube evaporator, one condenser, one condensed water collection tank, one vacuum pump, one feed pump, one discharge pump, without 2 refined o-nitroethylbenzene storage tanks (14000L) 3 refined o-nitroethylbenzene storage tanks, the required steam temperature is 6-8kgmpa.

[0014] 2. Put the o-nitroethylbenzene in the workshop into the storage tank and put it into the still for 1 hour, then put it into the distillation pot, the evaporator starts to heat up, and after the feed liquid is heated to boiling in the heating tube, part of it starts to vaporize, so that the heat energy is converted into The kinetic energy of the upward movement, at the same time, due to the gravity difference between the vapor-liquid mixture in the heating tube and the unboiled feed liquid in the circulation tube, under the induction of the expansion kinetic energy and the gravity difference, the autonom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com