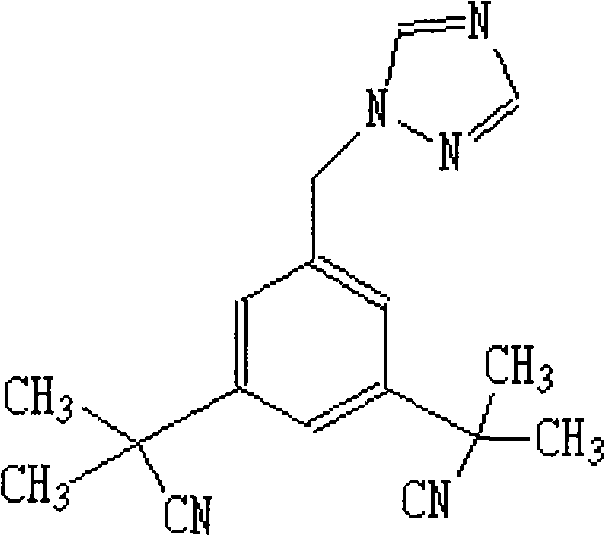

Method for synthesizing anastrozole

A synthesis method and technology of anastrozole, applied in the field of preparation of anastrozole, can solve the problems of unfavorable industrial production, increased risk and high cost, and achieve the effects of promoting development and application, reducing solvent consumption and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

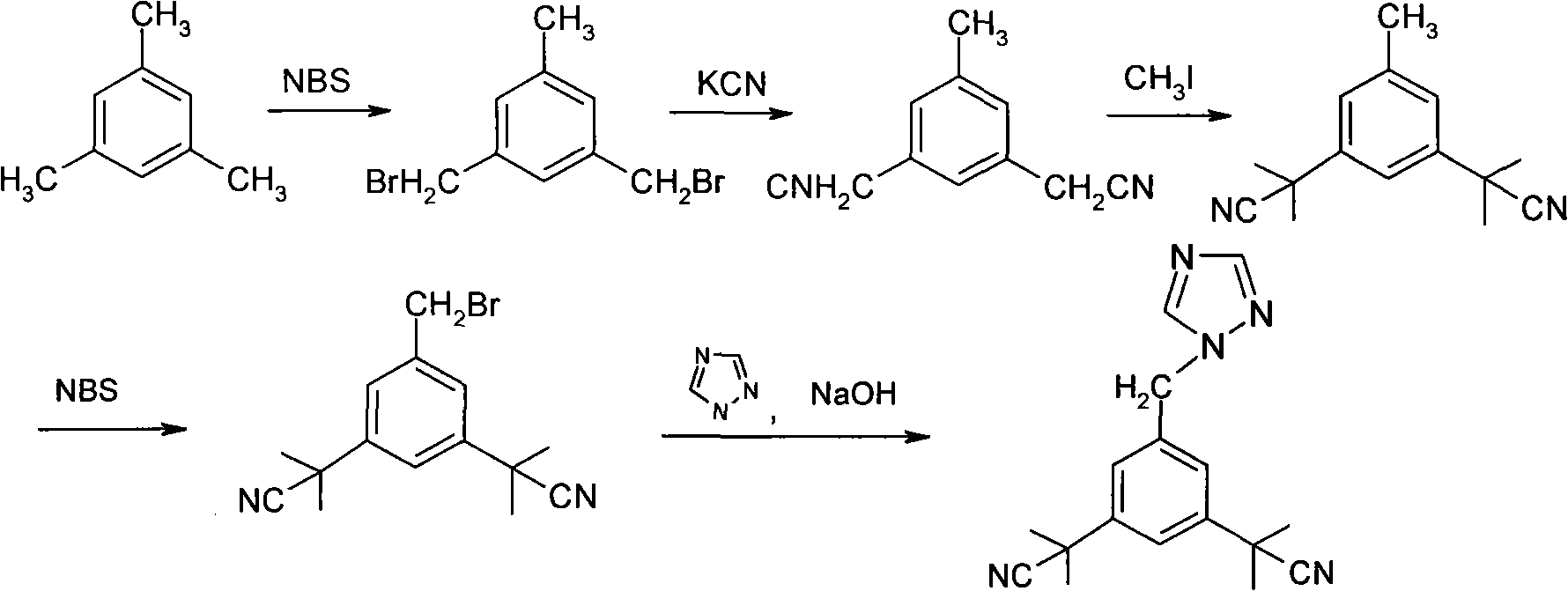

Method used

Image

Examples

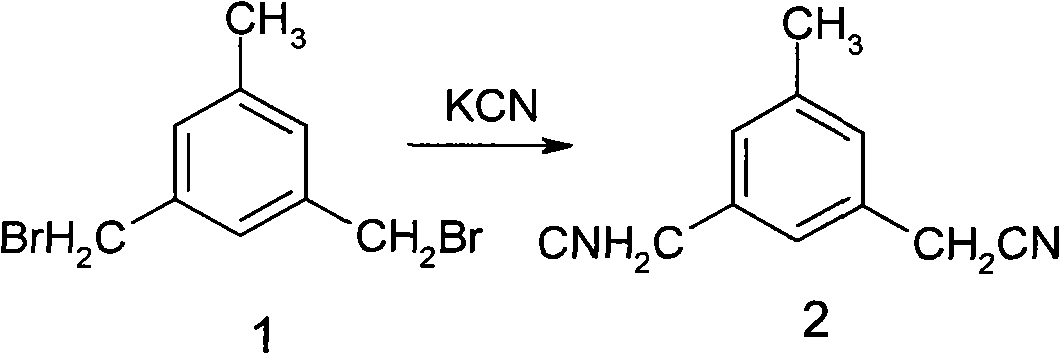

Embodiment 1

[0024] Get 8.10kg of intermediate 1 (29.2mol) and be dissolved in 81L of methylene chloride, 4.18kg of KCN (64.24mol) are dissolved in 50L of water, the resulting solution is added to the reactor respectively, then Tween-20 is added, and the reaction is stirred at 40°C , and react for 2 hours. After the reaction, the dichloromethane layer was separated, washed with water (20 L*2), dried and concentrated. The residue was crystallized with absolute ethanol to obtain 4.12 kg of white solid crystals of intermediate 3,5-dicyanomethyltoluene with a yield of 83.06%.

Embodiment 2

[0026] Get 8.10kg of intermediate 1 (29.2mol) and dissolve in 81L of chloroform, 4.18kg of KCN (64.24mol) is dissolved in 50L of water, the resulting solution is added to the reactor respectively, then polyethylene glycol 600 is added, and the reaction is stirred at 60 ° C, React for 2 hours. After the reaction, the chloroform layer was separated, washed with water (20 L*2), dried and concentrated. The residue was crystallized with absolute ethanol to obtain 4.29 kg of white solid crystals of intermediate 3,5-dicyanomethyltoluene with a yield of 86.42%.

Embodiment 4

[0028] Get 8.10kg intermediate 1 (29.2mol) and be dissolved in 81L carbon tetrachloride, 4.18kgKCN (64.24mol) is dissolved in 50L water, the solution of gained is added in the reactor respectively, then add 15-crown-5, in 50 The reaction was stirred at °C for 2 hours. After the reaction, the carbon tetrachloride layer was separated, washed with water (20 L*2), dried and concentrated. The residue was crystallized with absolute ethanol to obtain 4.37 kg of white solid crystals of intermediate 3,5-dicyanomethyltoluene with a yield of 88.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com