Sea tangle ultrafine powder fortified bread and preparation method thereof

A technology of ultra-fine flour and kelp, which is applied in the processing of dough, baking, and baked goods, etc., can solve problems such as unfavorable storage and loss of nutrients, and achieve the effects of improving bioavailability, rich flavor, and good color and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1 Materials and methods

[0049] 1.1 Experimental materials

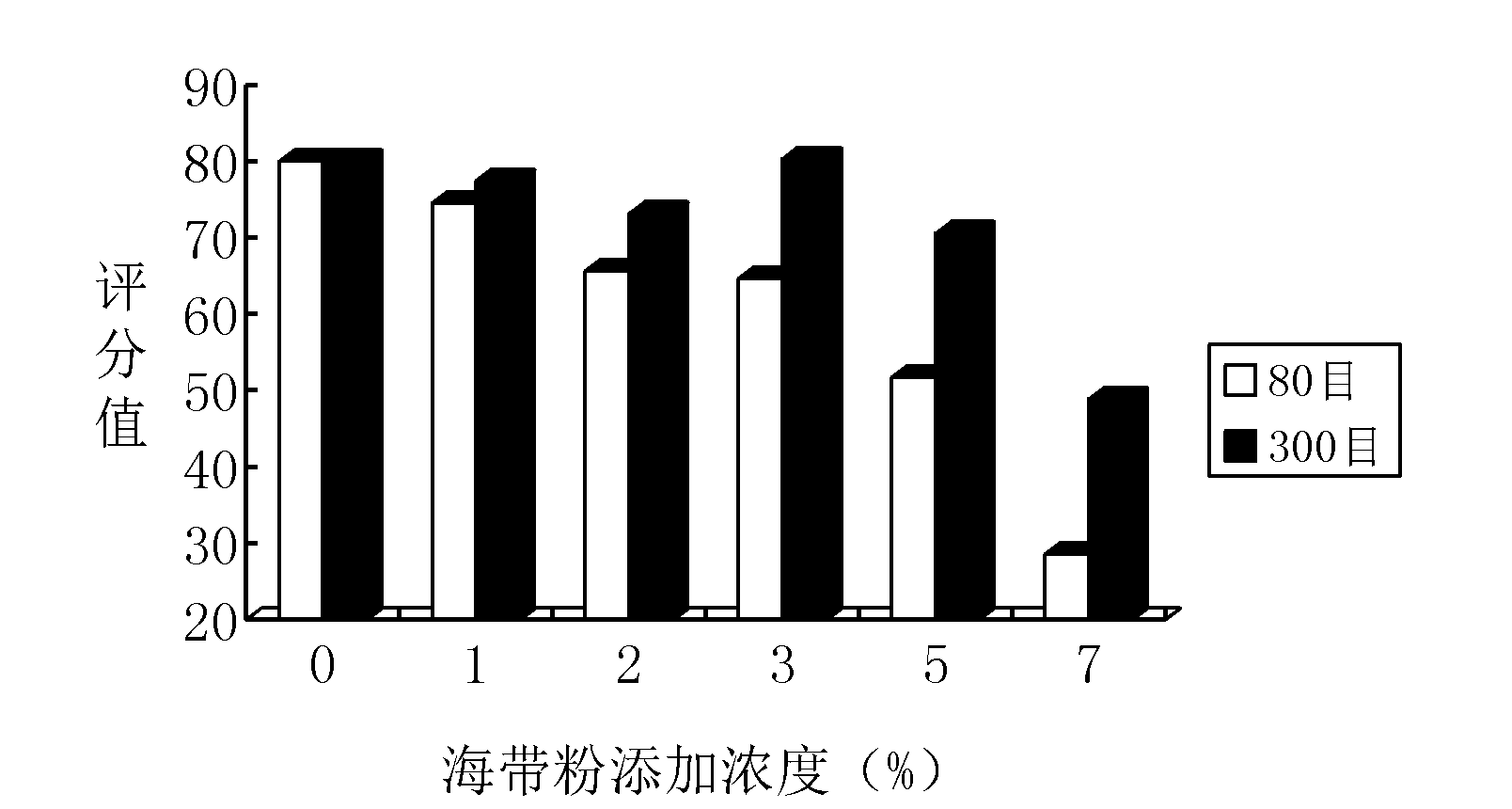

[0050] Kelp superfine powder: 80 mesh and 300 mesh kelp powder.

[0051] High-gluten flour, bread improver, high-active dry yeast, milk powder, salt, vegetable oil, sugar, water, eggs.

[0052] 1.2 Test equipment

[0053] WJZ-6 Bailey powder machine, electric bread fermentation box, far-infrared electric food oven, electronic balance, measuring cylinder, beaker, ruler.

[0054] 1.3 Test method

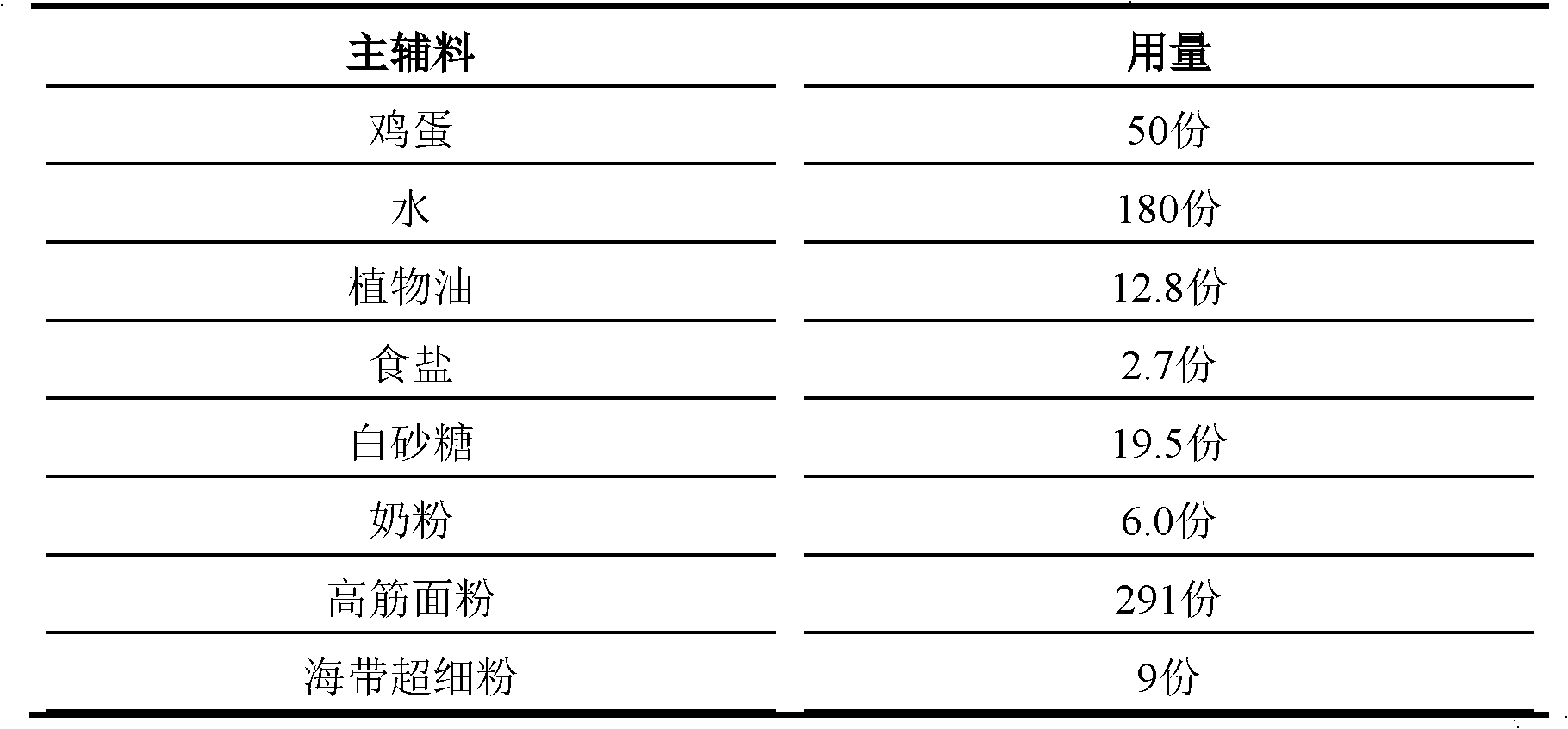

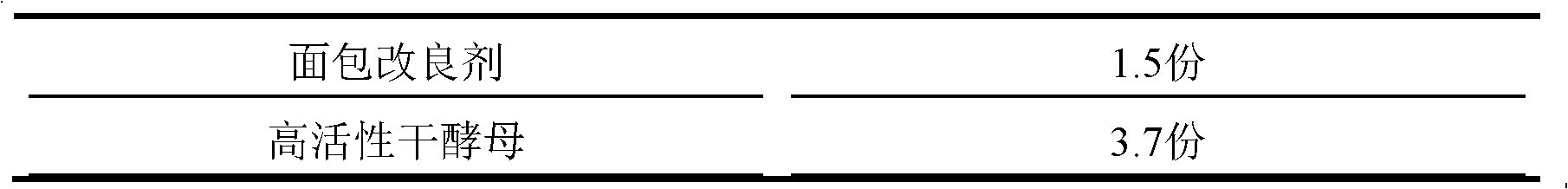

[0055] 1.3.1 Basic formula of bread

[0056] The selected basic formula is shown in Table 1

[0057] The basic formula of table 1 bread

[0058]

[0059]

[0060] 1.3.2 Bread making process

[0061] The one-time fermentation method is adopted, and the technological process is as follows: preparation of kelp superfine powder→dough preparation→dough fermentation→standing proof→baking.

[0062] 1.3.3 Key points of process operation

[0063] (1) Dough preparation

[0064] First add 150 parts of water into ...

Embodiment 2

[0113] Embodiment 2: a kind of kelp superfine powder nutritious bread comprises the following components by weight:

[0114] 280 parts of high-gluten flour;

[0115] 3 parts kelp superfine powder;

[0116] 0.5 parts of bread improver;

[0117] 3 parts high active dry yeast;

[0118] 1 part milk powder;

[0119] 1 part table salt;

[0120] 10 parts vegetable oil;

[0121] 16 parts white sugar;

[0122] 150 parts of water;

[0123] 10 servings of eggs.

[0124] The kelp superfine powder is 300 mesh kelp superfine powder.

[0125] A preparation method of kelp superfine powder nutritious bread adopts a fermentation method, comprising the following steps:

[0126] 1) Preparation of kelp superfine powder; use WJZ-6 Bailey micronizer to grind kelp to 300 mesh;

[0127] 2) Dough preparation, according to the aforementioned weight requirements, first add 130 parts of water to the dough mixer, then add refined salt, white sugar, milk powder and bread improver, stir well, emuls...

Embodiment 3

[0134] Embodiment 3: a kind of kelp superfine powder nutritious bread comprises the following components by weight:

[0135] 297 parts of high-gluten flour;

[0136] 20 parts of superfine kelp powder;

[0137] 1.5 parts of bread improver;

[0138] 4 parts high active dry yeast;

[0139] 6 servings of milk powder;

[0140] 5 parts table salt;

[0141] 16 parts vegetable oil;

[0142] 25 parts white sugar;

[0143] 190 parts of water;

[0144] 50 servings of eggs.

[0145] The kelp superfine powder is 300 mesh kelp superfine powder.

[0146] The preparation method of kelp superfine powder nutritious bread adopts a fermentation method, comprising the following steps:

[0147] 1) Preparation of kelp superfine powder; use WJZ-6 Bailey micronizer to grind kelp to 300 mesh;

[0148] 2) Dough preparation, according to the aforementioned weight requirements, first add 150 parts of water to the dough mixer, then add refined salt, white sugar, milk powder and bread improver, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com