Method for preparing high-hydrophobic polyester

A hydrophobic, polyester technology, applied in nanotechnology for materials and surface science, fiber processing, textiles and papermaking, etc., can solve the limitations of large-scale application of hydrophobic materials, expensive raw material preparation conditions, insufficient hydrophobic surface effect ideals etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Take the PET film as a sample, put it in o-chlorophenol:dichloroethane (1:2) solution at 20°C, take it out after 15s, put it in acetone solution quickly, take it out after 1min, and dry it.

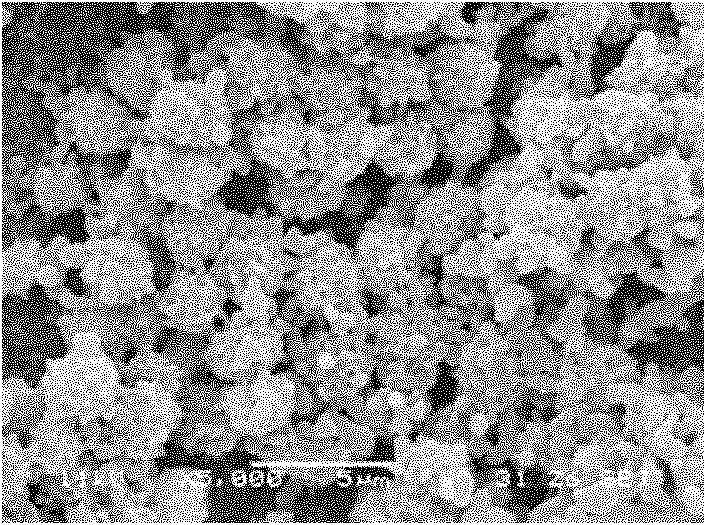

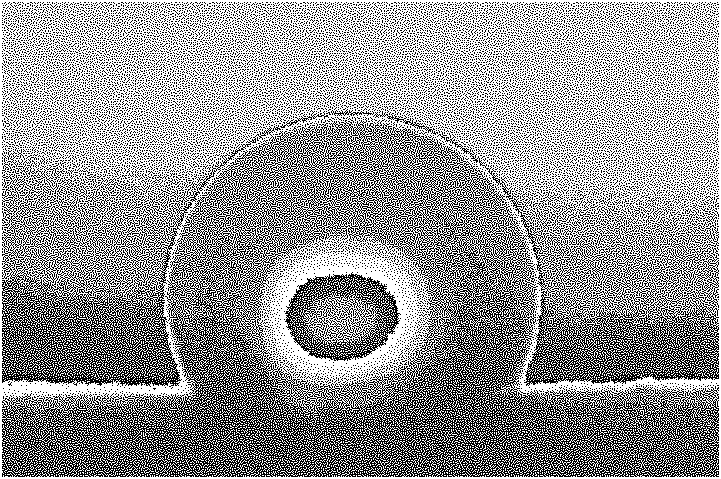

[0094] After the resulting treatment, the particles on the surface of the polyester film are evenly distributed, and observed under a scanning electron microscope at 5000 times, the surface SEM image is as follows figure 1 As shown, the measured diameter is 1.5-2 μm, the single particle is porous and honeycomb-shaped, and the contact angle is 118.4°. The photo of the contact angle is as follows figure 2 shown.

Embodiment 2

[0096] Take the polyester film in Patent Application No. 200910312659X as a sample. The structural formula of the polyester used is shown as IA. Put it in the nitrobenzene solution at 40°C, take it out after 30s, put it in the ethanol solution quickly, take it out after 1min, drying.

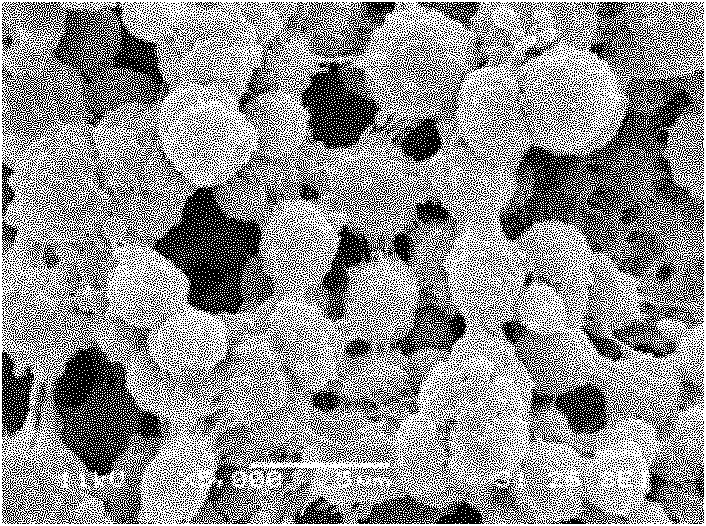

[0097] After the resulting treatment, the particles on the surface of the polyester film are evenly distributed, and observed under a scanning electron microscope at 5000 times, the surface SEM image is as follows image 3 As shown, the diameter is 2.5~3.5μm, the individual particles are distributed in flakes, and the contact angle is 144.5°. The contact angle photo is as follows Figure 4 shown.

[0098]

Embodiment 3

[0100] Taking the polyester film in the patent application number 200910312659X as a sample, the structural formula of the polyester used is as shown in IA, at 23°C, put it in cresol:tetrachloroethane (4:1) solution, take it out after 90s, and put it away quickly Put it into methanol solution, take it out after 1min, and dry it.

[0101] After the resulting treatment, the particles on the surface of the polyester film are evenly distributed, and observed under a scanning electron microscope at 5000 times, the surface SEM image is as follows Figure 5 As shown, the particle size is 1-2 μm, the surface morphology is tree-like, and the individual particles are flake-like; the contact angle is 140.5°, and the photo of the contact angle is as follows: Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com