Preparation method and application of nitrogen-doped carbon nanotube to preparing cathode of microbial fuel cell of

A fuel cell cathode, nitrogen-doped carbon technology, applied to battery electrodes, circuits, electrical components, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

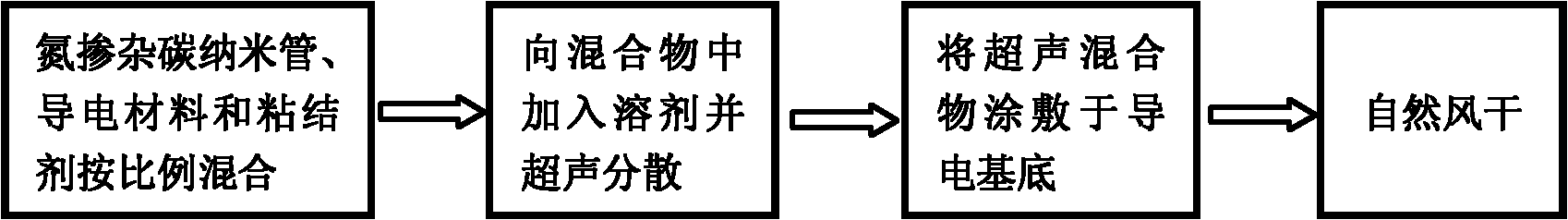

[0037] Step 1: Electrode Preparation

[0038] Mix nitrogen-doped carbon nanotubes, conductive materials, and binders in a mass ratio of 10:31:63, and add isopropanol reagent for ultrasonic dispersion for 30 minutes; spread the ultrasonic mixture evenly on carbon fiber cloth, and let it dry naturally for 24 minutes. Nitrogen-doped carbon nanotube catalytic electrodes were prepared within hours. Pt / C catalytic electrodes can be prepared by mixing conventional Pt / C catalysts, conductive materials and binders in the same way.

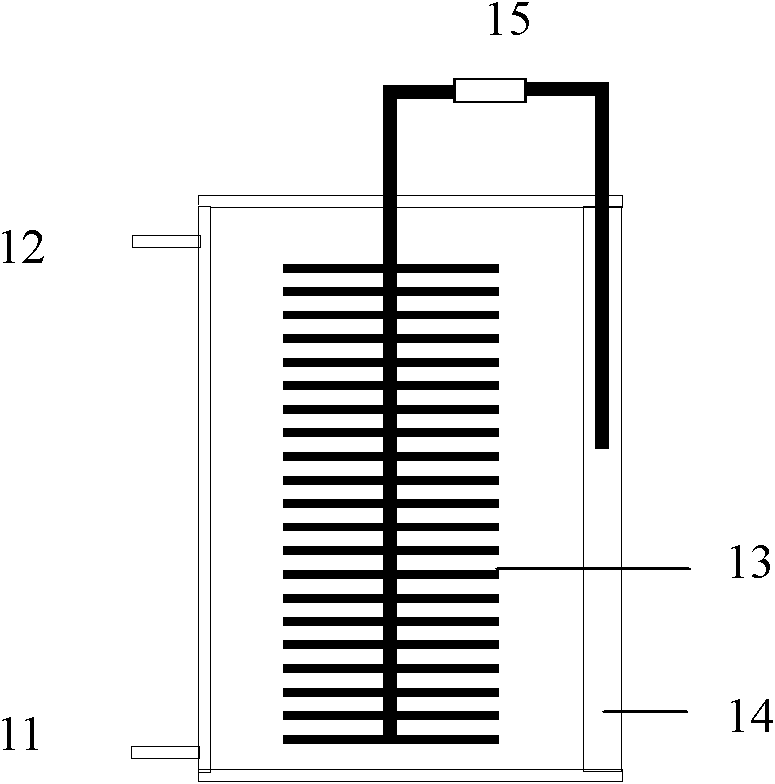

[0039] Step 2: Single-chamber microbial fuel cell performance test

[0040] as attached figure 2 As shown, 15mL of electrogenic microbial bacterial solution was loaded into a single-chamber microbial fuel cell from the inlet, and the nitrogen-doped carbon nanotube catalytic electrode and the Pt / C catalytic electrode prepared above were used as the cathode of the fuel cell. Connect the fuel cell to a 1000-ohm external resistance circuit, start recording ...

Embodiment 2

[0045] Step 1: Electrode Preparation

[0046] The electrode fabrication steps of Example 2 are as described in Example 1.

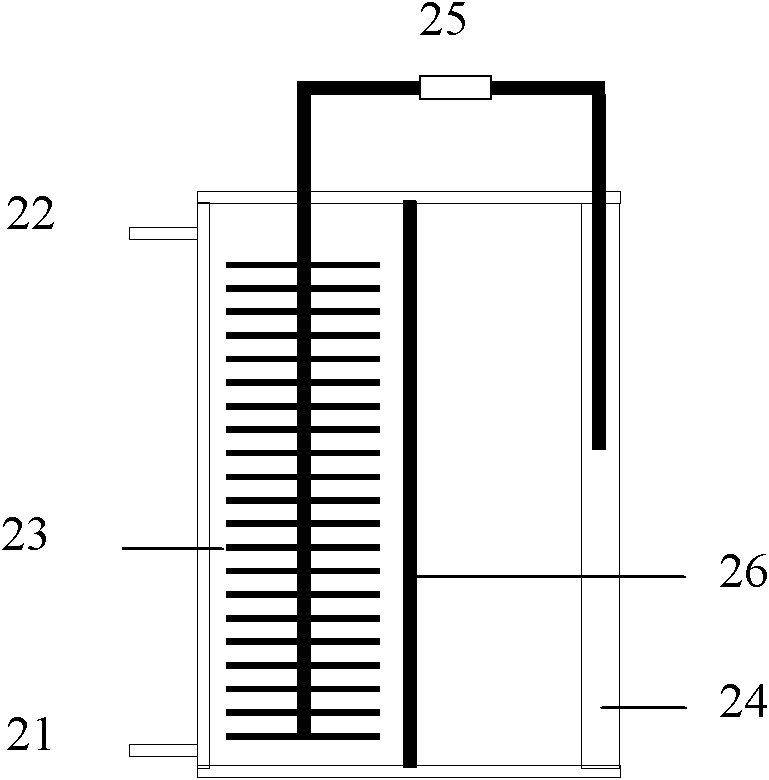

[0047] Step 2: Dual-chamber microbial fuel cell performance test

[0048] as attached image 3 As shown, 15mL of electrogenic microbial liquid was loaded into the anode of the dual-chamber microbial fuel cell from the inlet, and the nitrogen-doped carbon nanotube catalytic electrode and the Pt / C catalytic electrode prepared above were respectively used as the cathode of the fuel cell. The operating steps of the microbial fuel cell power generation performance test in Example 2 are as described in Example 1. The performance of microbial fuel cells with different catalytic electrodes is shown in Table 2.

[0049] Table 2 Performance comparison of dual-chamber microbial fuel cells with different catalytic electrodes

[0050]

[0051] It can be seen from Table 2 that, compared with conventional Pt / C catalysts, nitrogen-doped carbon nanotubes used as ox...

Embodiment 3

[0053] Step 1: Electrode Preparation

[0054] The electrode fabrication steps of Example 3 are as described in Example 1. The nitrogen-doped carbon nanotubes, the conductive material and the binder are fully mixed according to the mass ratio of 10:15:32.

[0055] Step 2: Single-chamber microbial fuel cell performance test

[0056] The operating steps of the microbial fuel cell power generation performance test in Example 3 are as described in Example 1. The performance of microbial fuel cells with different catalytic electrodes is shown in Table 3.

[0057] Table 3 Performance comparison of single-chamber microbial fuel cells with different catalytic electrodes

[0058]

[0059] It can be seen from Table 3 that compared with conventional Pt / C catalysts, nitrogen-doped carbon nanotubes have higher catalytic activity and stability as oxygen reduction catalysts for single-chamber microbial fuel cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com