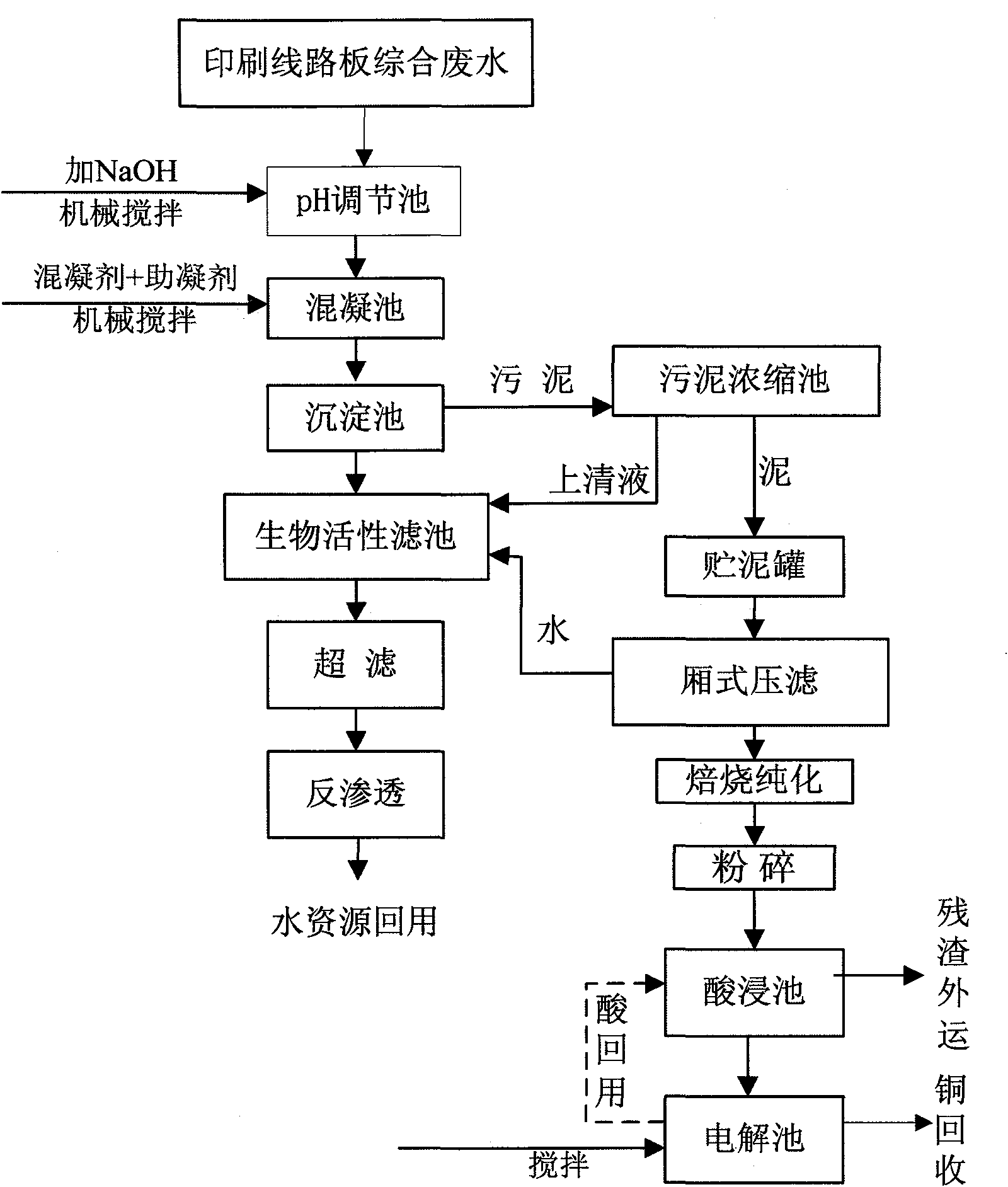

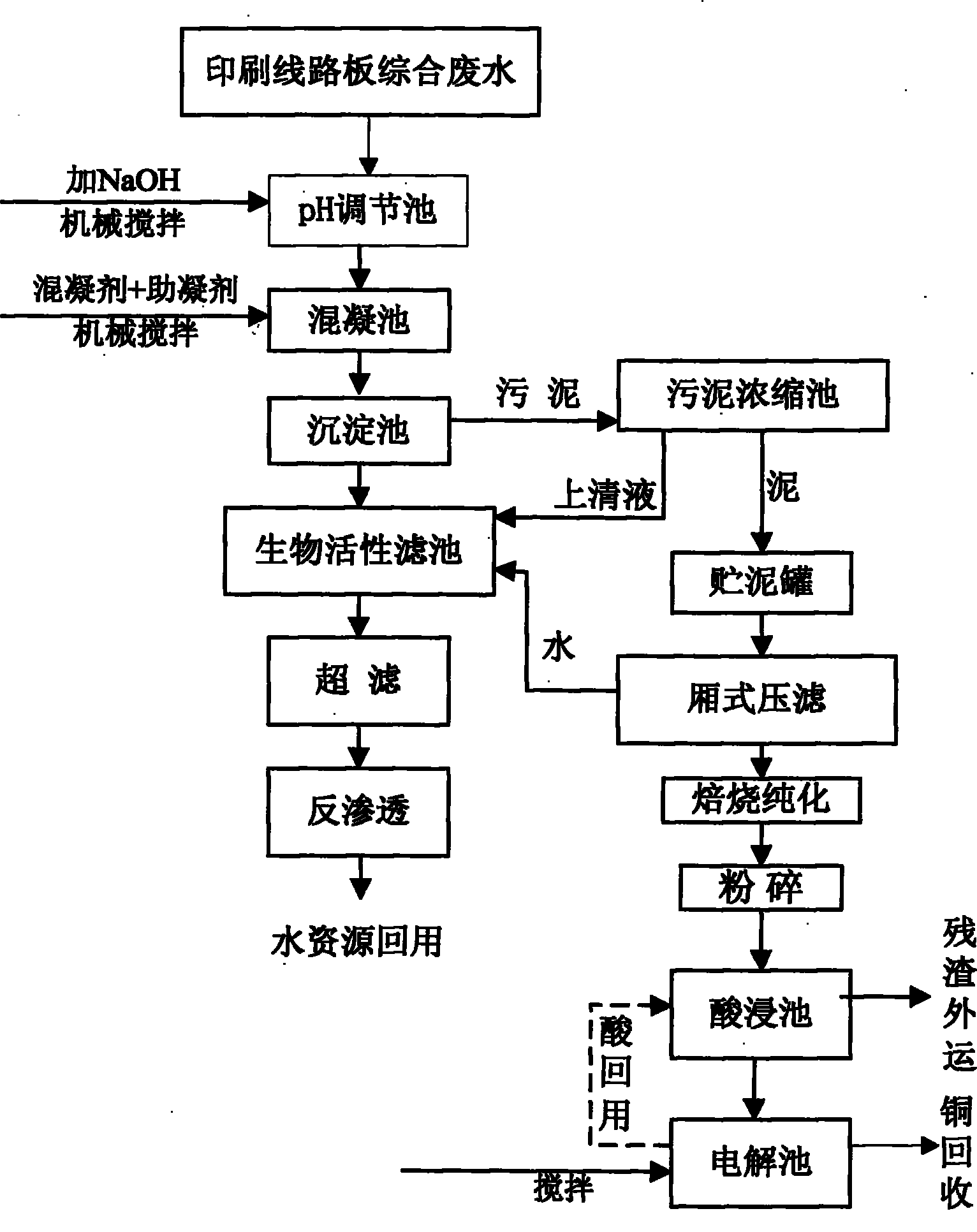

Printed circuit board integrated wastewater resource utilization method

A printed circuit board and comprehensive wastewater technology, which is applied in the field of environmental protection and environmental engineering, can solve the problems of large floor area, non-recyclable wastewater, and large sludge production, so as to realize recycling, complete system, and unified economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1) pH adjustment: The pH of PCB comprehensive wastewater is generally between 2 and 3. The adjustment tank is equipped with an automatic online pH control device and a mixer, and the pH is raised to about 8 to ensure the best coagulation and precipitation conditions for copper ions.

[0021] 2) Coagulation and sedimentation: the effluent from the pH adjustment tank is pumped into the high-level water tank, and then flows into the coagulation tank through the high-level water tank. Added in the pipeline, the concentrations of PAC and PAM were 5% and 0.1%, respectively. The mechanical coagulation tank is divided into three grids, the number of revolutions of the impeller can be adjusted according to the water quantity and quality, and the number of revolutions of the stirring impeller decreases step by step to facilitate the formation of flocs. The vertical partition walls with water holes are used to guide the flow between the cells of the coagulation tank. The positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com